Upward-pulling type broaching machine toolchanger

A tool changing device and tool feeding technology, which is applied in the field of broaching machines, can solve the problems of high labor intensity of operators, inability to realize automation, and reduce production efficiency, etc., and achieve the goal of solving uneven broaching, realizing manufacturing automation, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

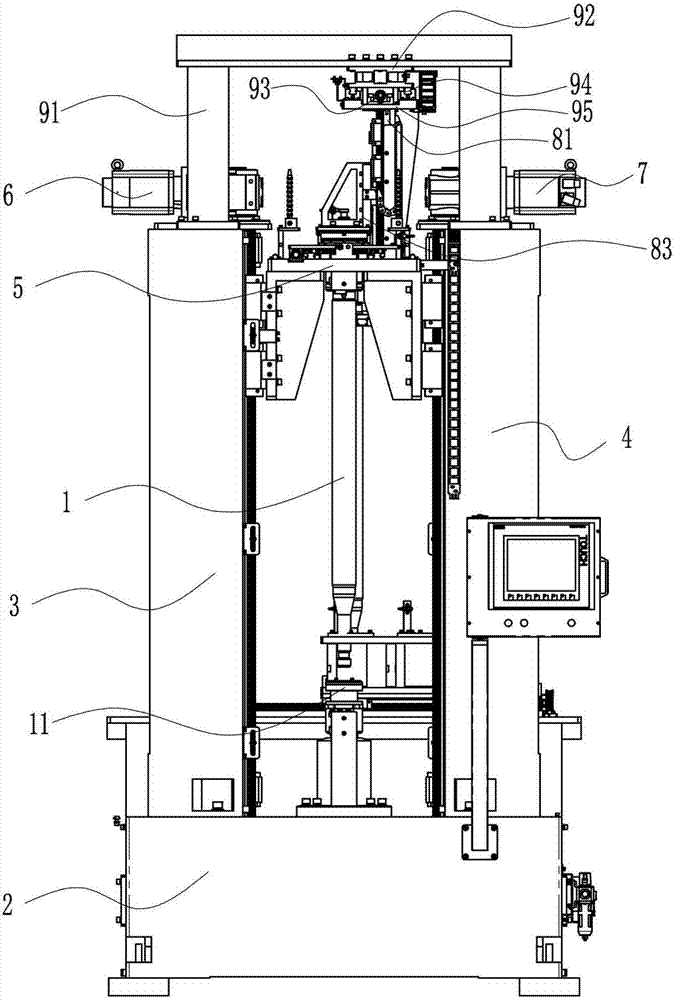

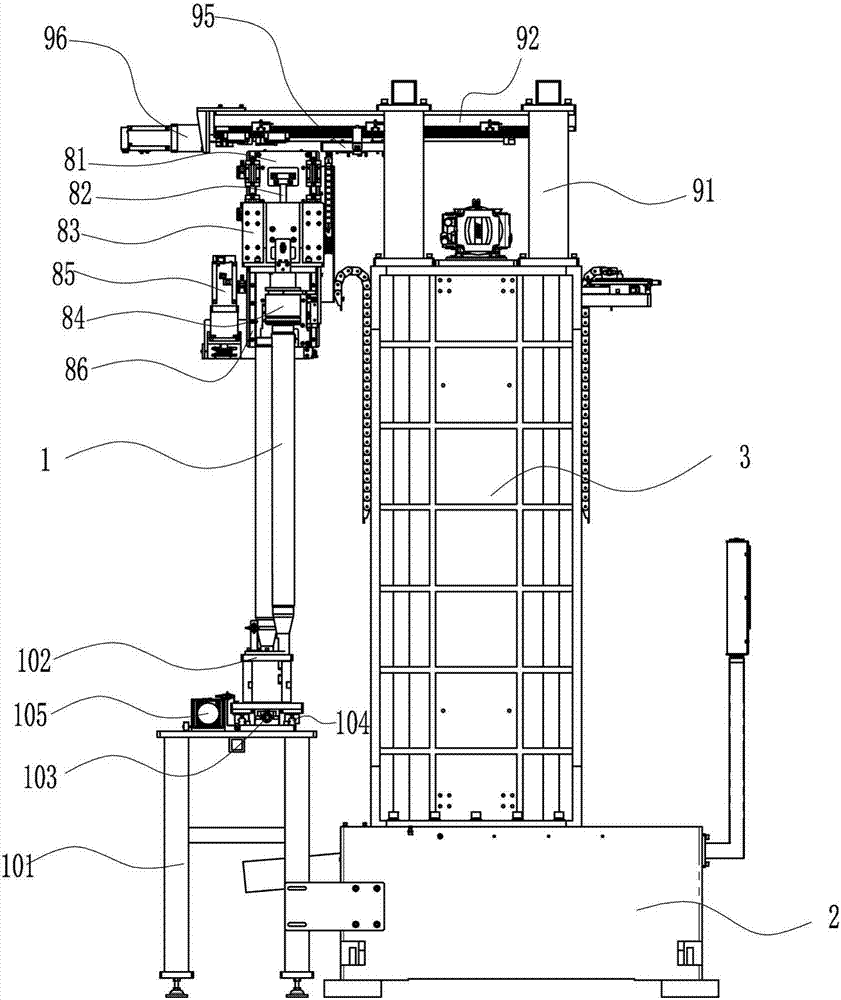

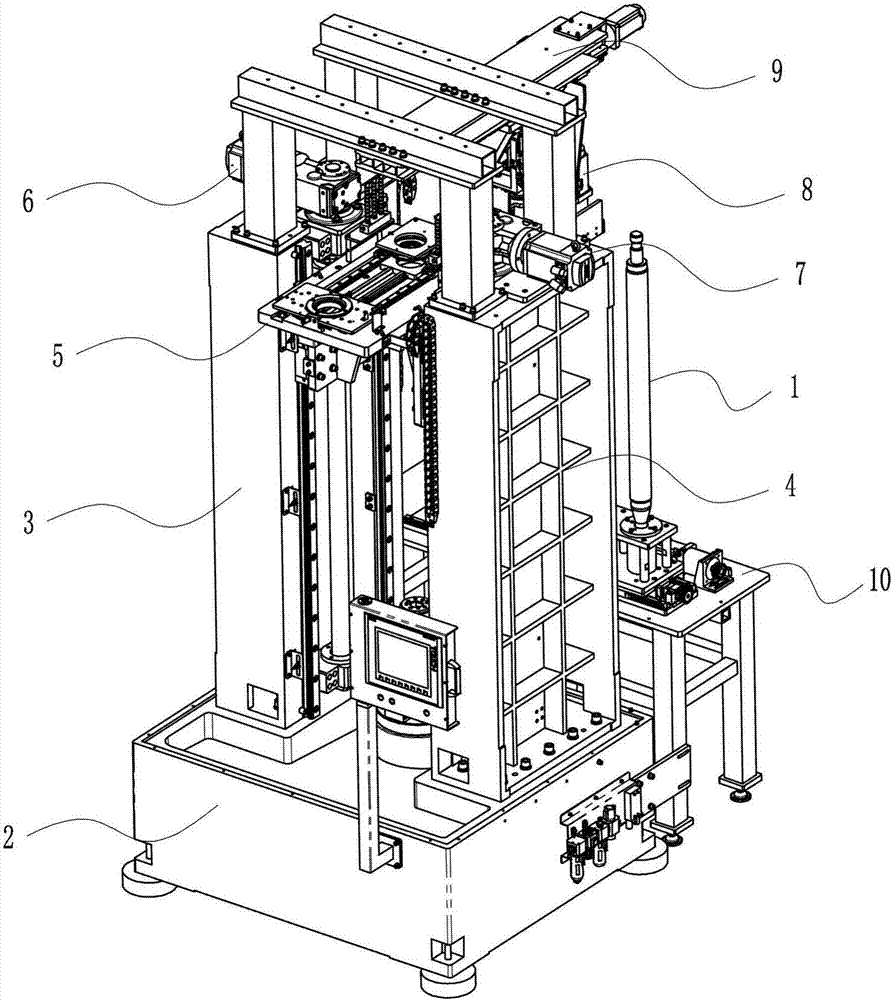

[0028] A tool changing device for a pull-up broaching machine, such as Figure 1 to Figure 4 As shown, it includes a base 2, a bed vertically fixed on the base 2, a lifting knife assembly 8, a tool changing assembly 9, and a tool magazine assembly 10 arranged beside the base 2; the tool changing assembly 9 is arranged on the bed, and The knife feeding assembly 8 is suspended and connected with the knife changing assembly 9;

[0029] The lifting knife assembly 8 includes a lifting knife bracket 81, a ball screw pair I82, a lifting knife slide plate 83, a clamping knife body I84 and a motor I85; the ball screw pair I82 and the motor I85 are installed on the lifting knife bracket On 81, the motor I85 is connected with the ball screw pair I82; the lifting knife slide plate 83 is connected with the ball screw screw set I82, and the lifting knife slide plate 83 is provided with a clamping knife body I84 matched with the top of the broach 1; The knife feeding bracket 81 is also prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com