Cleaning type cutting device

A technology for cutting devices and cleaning devices, which is applied in the direction of shearing devices, attachments of shearing machines, maintenance and safety accessories, etc., and can solve problems such as cutter wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

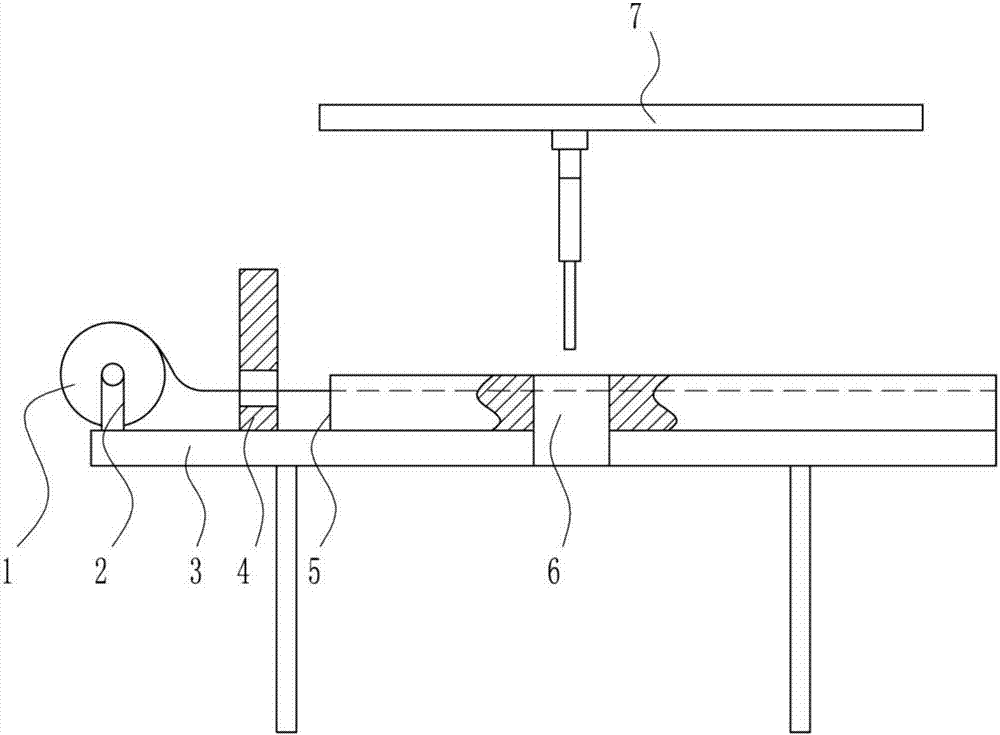

[0033] A clean cutting device such as Figure 1-9 As shown, it includes a winding reel 1, a first pole 2, a workbench 3, a rubber guide sleeve 4, a guide device 5 and a cutting device 7, and the first pole 2 is arranged on the workbench 3 from left to right. , rubber guide sleeve 4 and guide device 5, the first pole 2 tops are rotatably provided with take-up reel 1, the middle part of guide device 5 and workbench 3 has perforation 6, and guide device 5 is provided with cutting device 7 right above.

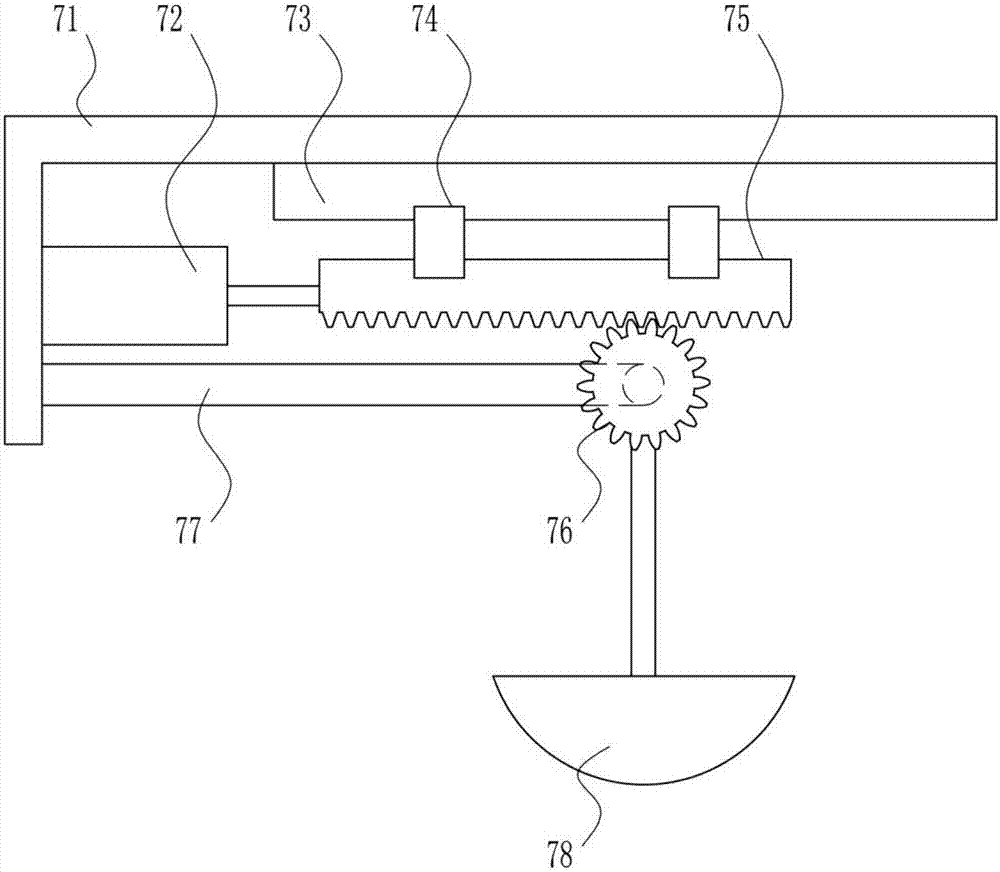

[0034] Cutting device 7 comprises support 71, cylinder 72, slide rail 73, slide block 74, rack 75, gear 76 and second pole 77, and support 71 inner top is provided with slide rail 73, and slide rail 73 is provided with slide block 74, the slide block 74 below is connected with a rack 75, the rear wall in the bracket 71 is provided with a cylinder 72 and a second pole 77, the second pole 77 is located below the cylinder 72, the front end of the cylinder 72 is connected with the rac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com