A plug-in sand injection nozzle with flexible installation of hot core box

A technology of sand injection nozzle and hot core box, which is used in casting and molding equipment, metal processing equipment, molding machines, etc. It can improve the efficiency of installation and debugging, overcome the low accuracy of alignment, and overcome the lack of structural flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

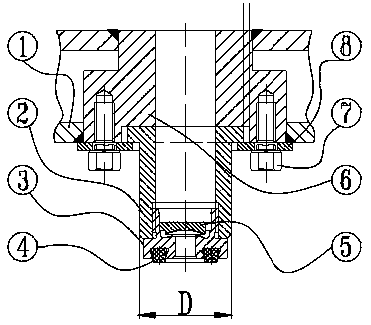

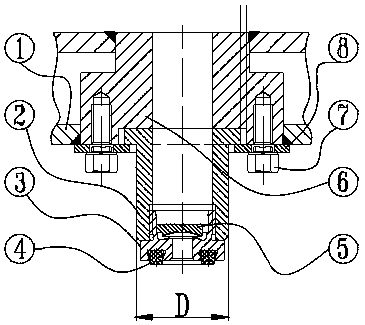

[0009] like figure 1 As shown, the present invention comprises the welding block 6 of the hot core box to install the sand shooting nozzle, the sand shooting plate 1 welded with the welding block, the sand shooting nozzle cap 3, the sealing ring 4, the sand blocking block 5, and is characterized in that the sand shooting nozzle 2 top is Flange or polished rod, the lower part of the welding block where the sandblasting nozzle is installed in the hot core box is provided with a groove that is compatible with the flange or polished rod on the upper part of the sandblasting nozzle. The inner diameter of the groove is 1-2 mm larger than the flange or polished rod. The outside of the groove is fixedly connected with the sand blasting nozzle, the welding block and the sand blasting plate as a whole through the screw 7 and the sand blasting nozzle limit ring 8 . The sand shooting board is made of cast iron or carbon steel. Including gray cast iron HT200, HT250, HT300, nodular cast ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com