Backlight module detection equipment and detection method

A backlight module and detection equipment technology, which is applied in optical instrument testing, machine/structural component testing, measuring devices, etc., can solve problems such as backlight module detection errors, unqualified product missed inspections, and prone to errors, etc., to achieve The effect of improving detection efficiency and reducing missed detection, reducing manual labor and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

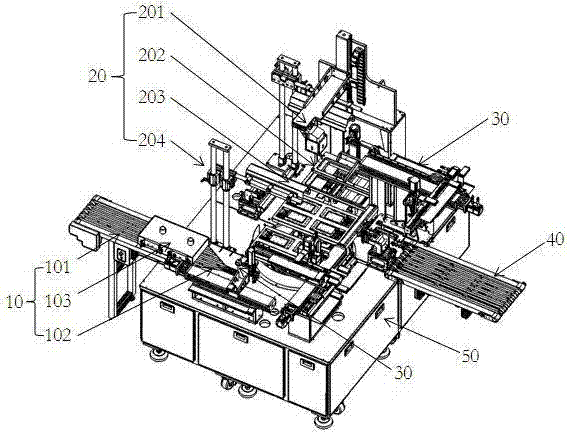

[0039] The present invention as figure 1 As shown, a detection device for a backlight module includes:

[0040] The feeding assembly line 10, the feeding assembly line 10 includes a feeding track 101, an incoming material sensor 102 and a dust removal device 103, the dust removal device 103 is located in the middle section of the feeding line 10, and the dust removal device 103 is sucked onto the feeding track 101 by ion wind blowing and a blower The backlight module is used for dust removal, and the incoming material sensor 102 is fixed at the end of the feeding track 101 in the conveying direction.

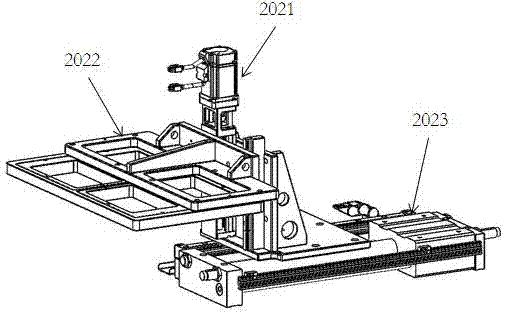

[0041] The detection machine 20 is located on one side of the feeding line 10, and includes a CCD detection device 201, a vacuum module 202, a detection station 203, and a light source 204. The CCD detection device 201 and the light source 204 are arranged above the detection station 203, and the vacuum module 202 and the detection station 203 are all fixed on the detection mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com