Vehicle body assembly quality online diagnosis method based on component measuring point distance abnormality judgment

A diagnostic method and component technology, applied in the direction of measuring devices, comprehensive factory control, instruments, etc., can solve problems such as multiple deviation sources that are difficult to diagnose, and achieve the effect of reducing losses and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

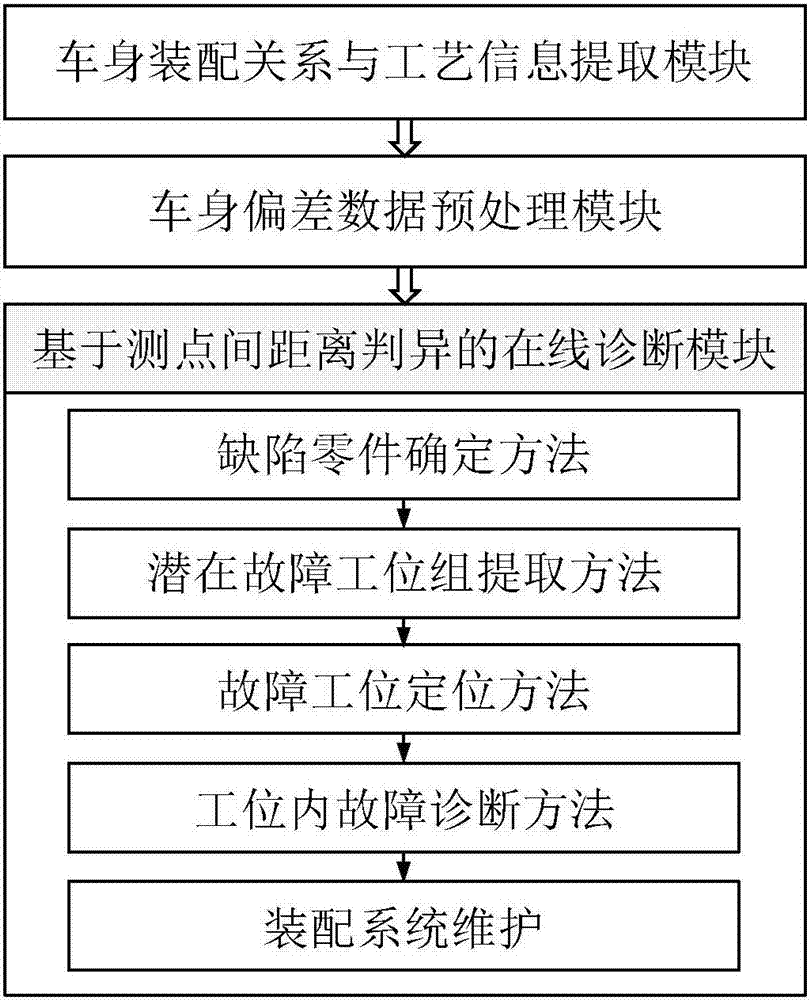

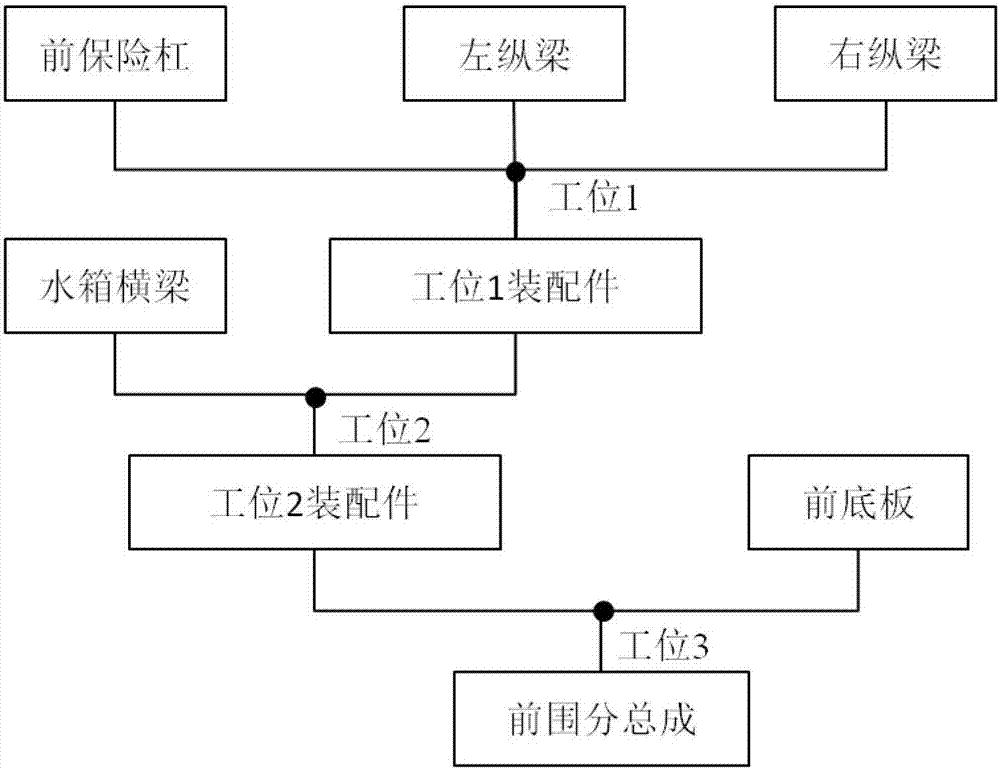

[0022] The body assembly quality online diagnosis system includes the body assembly relationship and process information extraction module, which is used to record the process information of the assembly process and realize the matching of all the stations designed for the faulty parts; the body deviation data preprocessing module is used to measure the three-coordinate instrument. The obtained body end data is preprocessed to extract the fluctuating measuring points; the online diagnosis module based on the distance discrimination between the measuring points is used to realize the diagnosis and analysis of the fault station of the body-in-white and the cause of the fault in the station, and guide the formulation of the maintenance strategy.

[0023] like figure 1 Shown is the system function module diagram of the online body assembly quality diagnosis system of the present invention. The specific steps of the online body assembly quality online diagnosis method based on the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com