Small-sized high-pressure self-locking valve

A self-locking valve, high-pressure technology, applied in valve details, valve device, valve operation/release device, etc., can solve the problems that cannot fully meet the use requirements of electric propulsion system, large volume, high power consumption, and achieve good sealing performance , reduce weight, enhance the effect of guiding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

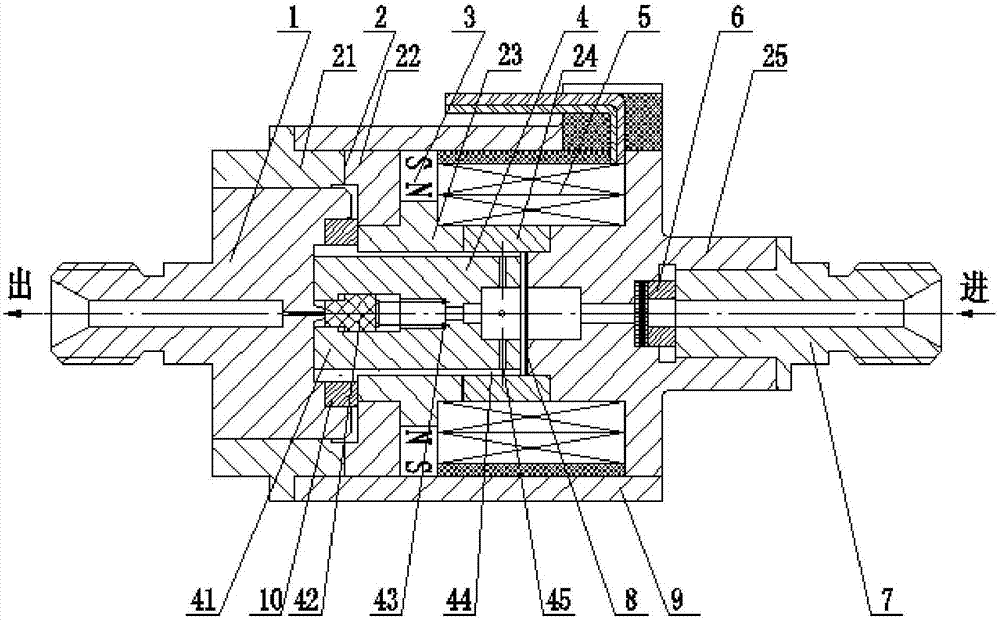

[0019] Such as figure 1 As shown, the embodiment of the present invention provides a small high-pressure self-locking valve, including a valve seat 1, a valve body 2, a permanent magnet 3, a valve core 4, a coil 5, a magnetic isolation gasket 8, a filter 6, and an inlet joint 7 It is connected with the casing 9, the valve seat 1, the valve body 2, the valve core 4, the magnetic isolation gasket 8, the filter 6, and the inlet joint 7 from left to right. The valve body 2 is a welded one-piece struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com