Method for treating foundation by vacuum prepressing method through positionable water permeable pipes

A foundation treatment and permeable pipe technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of high fluidity, high moisture content of muddy soil, and small water passing area of drainage boards, so as to increase the additional stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

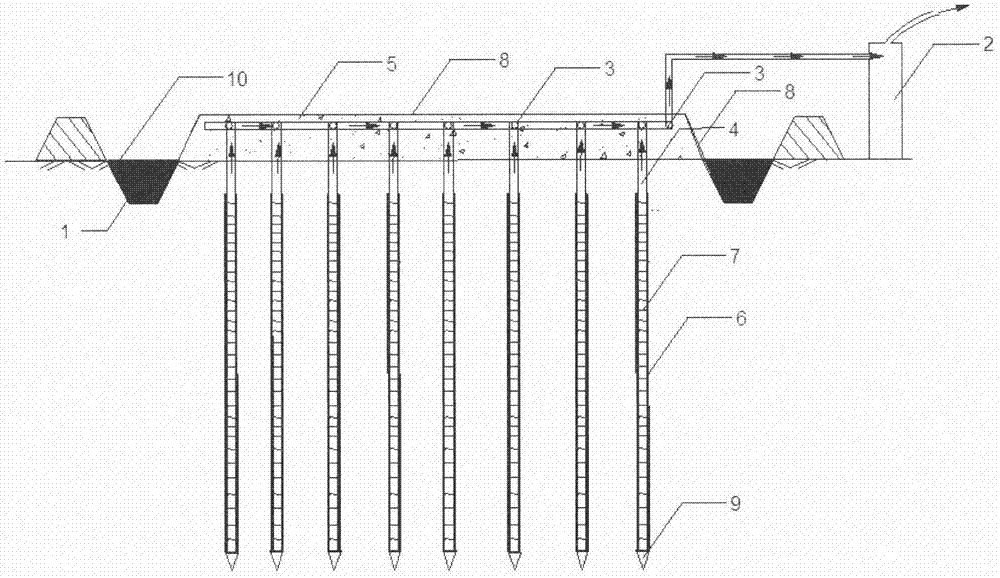

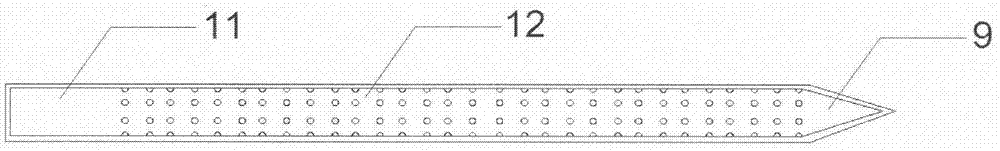

[0030] see figure 1 , a vacuum preloading ground treatment method using positionable permeable pipes, the adopted positionable permeable pipes include ordinary steel pipes 4 , filter screens 6 , lead wires 7 , and back-sealing steel sheets 9 . The steel pipe is drilled with holes with a diameter of Φ10mm and a center distance of 30mm in the designed drainage area. The outside of the steel pipe is wrapped with a filter screen 6 and fixed with a lead wire 7. The bottom of the permeable pipe is welded with a 4.0mm iron plate and covered with a rubber base.

[0031] A vacuum preloading foundation treatment method using a positionable permeable pipe according to the present invention comprises the following steps:

[0032] 1. Large-scale machinery enters the site, leveling the site, and excavating temporary drainage ditches to ensure that the surface water can be led out of the scope of foundation reinforcement treatment in time.

[0033] 2. The measuring engineer uses a level and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com