Ether carboxylic acid compound of water-based cutting solution,preparation method and water-based cutting solution

A technology of ether carboxylic acid and cutting fluid, which is applied in the field of water-based cutting fluid, can solve the problems of unsatisfactory foam and hard water resistance, high cost, etc., and achieve the effect of excellent biodegradability, low cost, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

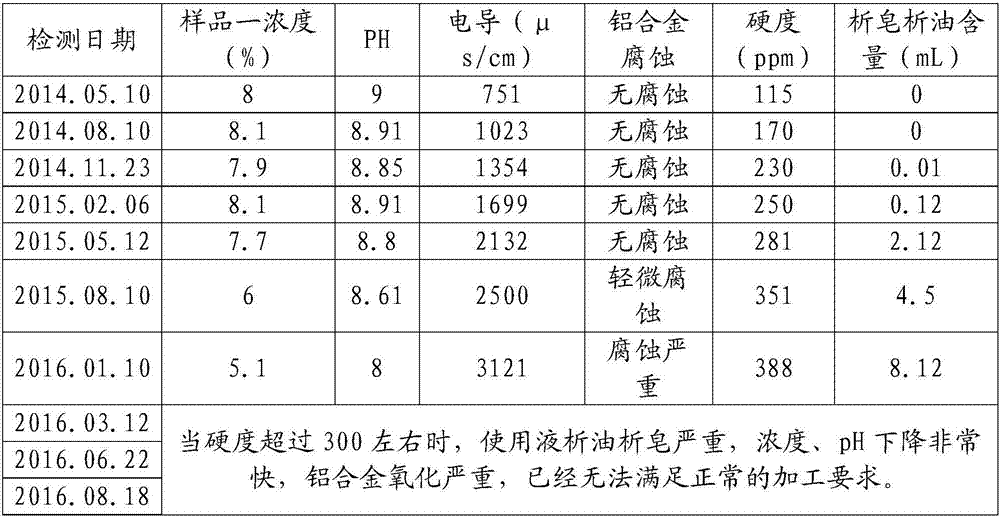

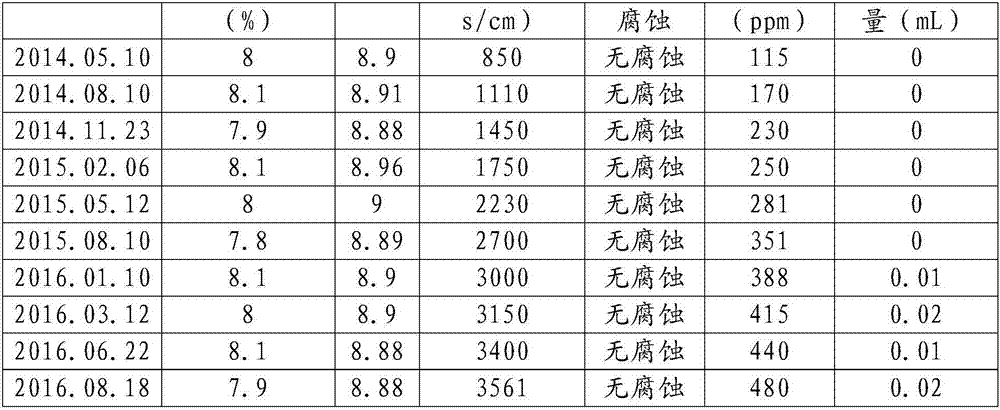

[0045] Take an ordinary water-based cutting fluid A, sample 1: add 0.5% EmulsogenCOL 100 to water-based cutting fluid A; sample 2: add 0.5% ether carboxylic acid compound package 1 to water-based cutting fluid A. Two samples were obtained for product processing. Die-casting aluminum alloy was processed on two identical CNC machines. The liquid tank was 200L. The experimental data are as follows:

[0046]

[0047]

[0048]

[0049]Comparison results: 15-30L of 4% new liquid is added to the CNC processing tanks of sample 1 and sample 2 every shift (12h) to ensure that the tank is about 180L. After sample 1 was 2016.01.10, the concentration could not be increased, and the liquid used was separated and could not be used. Sample 2 is used normally. The results show that the effect of adding a single ether carboxylic acid to cutting fluid A is not as good as that of ether carboxylic acid compound package 1.

Embodiment 2

[0051] Take the same ordinary water-based cutting fluid A, sample 3: add 1% Akypo LF4 to water-based cutting fluid A; sample 4: add 1% ether carboxylic acid compound package 1 to water-based cutting fluid A. Two samples were obtained for product processing. Die-casting aluminum alloy was processed on two identical CNC machines. The liquid tank was 200L. The experimental data are as follows:

[0052]

[0053]

[0054]

[0055] Comparison results: 15-30L of 4% new liquid is added to the CNC processing tanks of sample 3 and sample 4 every shift (12h) to ensure that the tank is about 180L. The concentration of sample three cannot be increased after January 1, 2016, and the liquid used is separated and cannot be used. Sample four is used normally. The results show that the addition of a single ether carboxylic acid to cutting fluid A is not as effective as the ether carboxylic acid compound package 1.

Embodiment 3

[0057] Take the same common water-based cutting fluid A, sample five: add 0.5% Akypo LF4 and 0.5% Akypo RO 90 VG to water-based cutting fluid A; sample four: add 1% ether carboxylic acid to water-based cutting fluid A Compound package one. Two samples were obtained for product processing. The die-casting aluminum alloy was processed on two identical CNC machines. The liquid tank was 200L. The experimental data are as follows:

[0058]

[0059]

[0060]

[0061] Comparison results: 15-30L of 4% new liquid is added to the CNC processing tanks of sample 5 and sample 4 every shift (12h) to ensure that the tank is about 180L. The concentration of sample 5 cannot be increased after 2016.01.1, and the liquid used is separated and cannot be used. Sample four is used normally. The results show that the effect of adding the two ether carboxylic acids to the cutting fluid is not as good as that of the ether carboxylic acid compound package one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com