Bionic step element

A ladder and component technology, applied in the field of integral die-casting aluminum parts, can solve the problems of lack of commercial vitality and a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

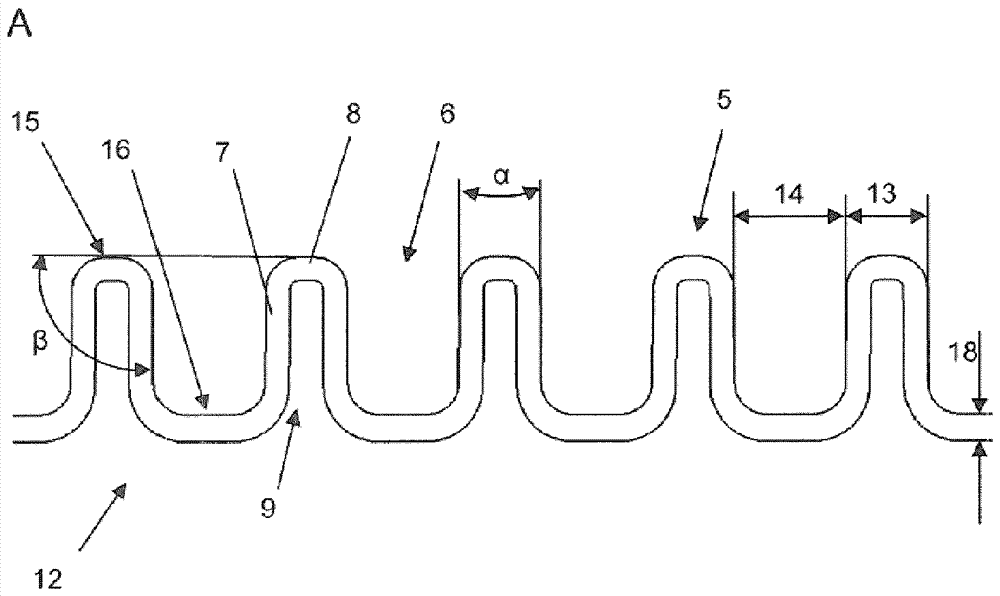

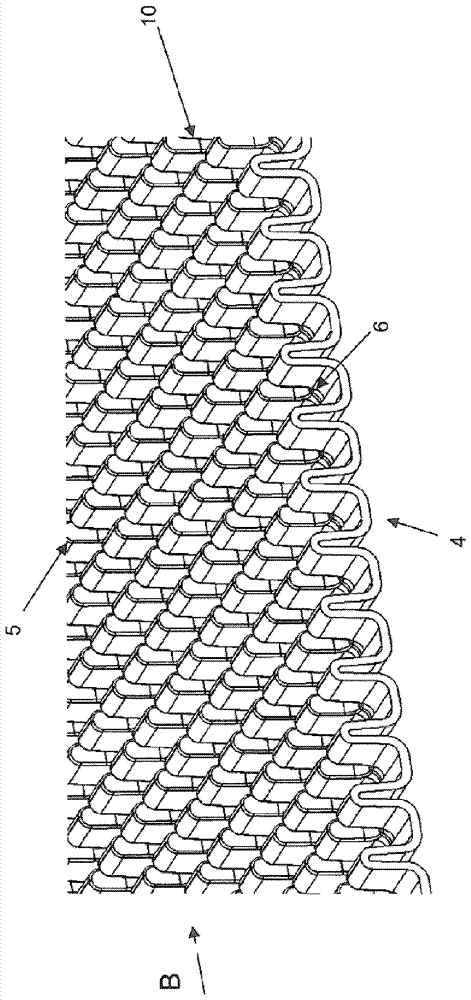

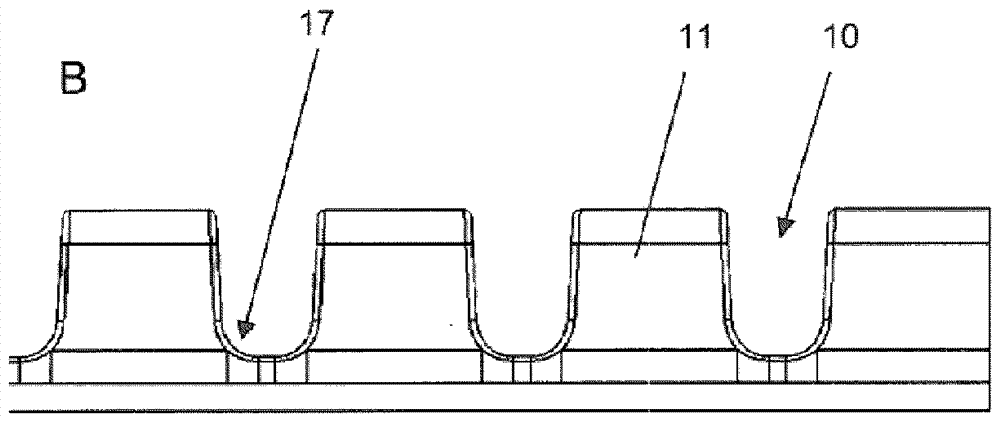

[0057] figure 1 A three-dimensional view of a step element 1 for an escalator is shown. However the invention is equally applicable to the step elements of moving walks, even though these are not shown in the figures.

[0058]The stepped element 1 is configured as a one-piece die-cast aluminum part, whereby expensive assembly processes for the stepped element 1 can be avoided. The ladder element 1 comprises a ladder element skeleton 2, preferably formed by longitudinal and transverse stringers and ribs. The stepped element skeleton 2 is configured according to the desired use. The step element 1 for moving walkways and for escalators comprises a step element skeleton 2 of this type, wherein the skeleton 2 has the task of passing through completely rigid step elements 1 or The ladder element skeleton 2 forms a moving system. All ladder element skeletons 2 thus have to fulfill the same task, and the exact path and exact placement of the longitudinal and transverse webs and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com