Crop straw forming device

A technology for crop straw and molding equipment, which is applied to material molding presses, presses, manufacturing tools, etc., can solve the problems of wasting resources, difficult to crush, and difficult to compress, and achieves simple structure, high extrusion density, and practical effects. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

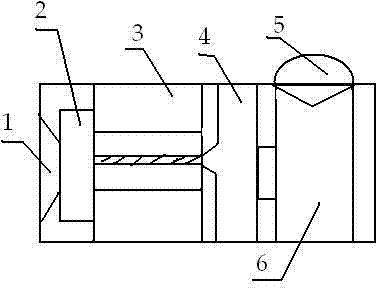

[0011] See attached picture

[0012] The present invention includes an inlet 5 and a packaging device 2, a heating chamber 6 is provided below the inlet 5, a plasma rotary mechanism 4 is provided on one side of the heating chamber 6, and an extrusion mechanism is provided on one side of the plasma rotary mechanism 4 3. The extruding mechanism 3 is connected to the packaging device 2 through a pipeline.

[0013] The working principle is: under the control of the control system, the material enters the heating chamber 6 from the inlet 5. After heating up, it enters the ion rotary mechanism 4 under the suction of the plasma rotary mechanism 4 for dehydration, dehumidification and drying. Extrusion mechanism 3 carries out extrusion, after that, after packaging device 2 carries out packaging, it is separated from finished product outlet 1. The invention mainly aims at the ash stalk crops such as cotton stalks and willow halberds, which have many lignin, are difficult to crush and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com