Control method for cooperative work of multi-blade collimator blades based on cross coupling

A multi-leaf collimator and cross-coupling technology, which is applied in the controller, adaptive control, electric controller and other directions with specific characteristics, can solve the problems such as the deviation of the blade position accuracy, and achieve the effect of compensating for the deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

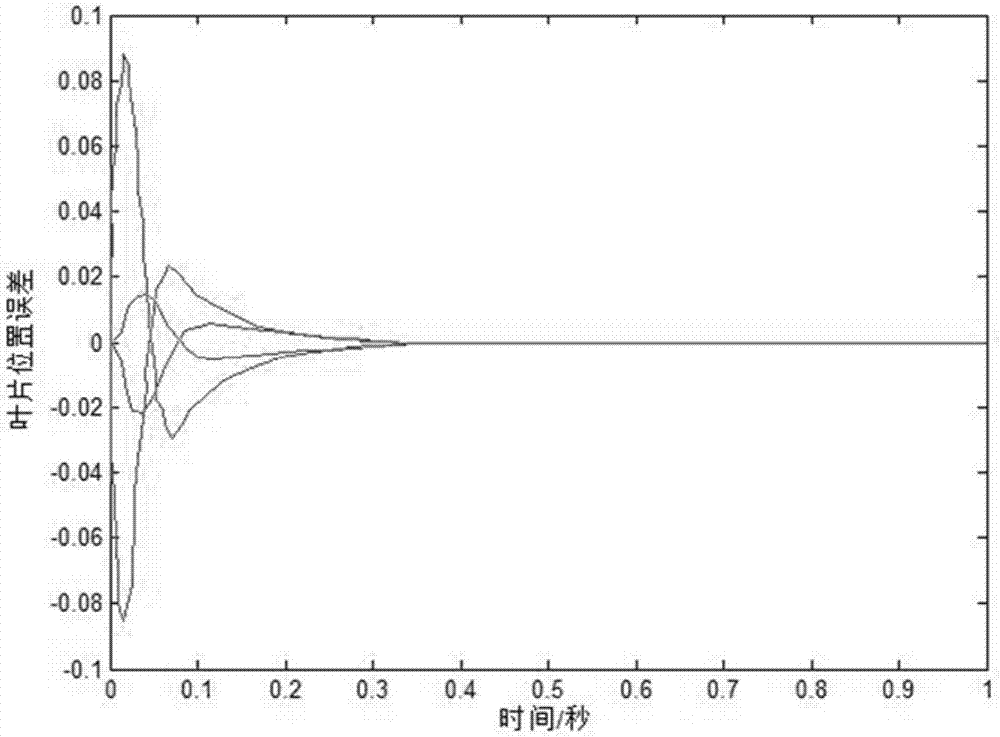

[0041] The present invention and its effects will be further described below in conjunction with the accompanying drawings and embodiments.

[0042] Such as figure 1 As shown, a control method based on cross-coupling multi-leaf collimator blades working together includes the following steps:

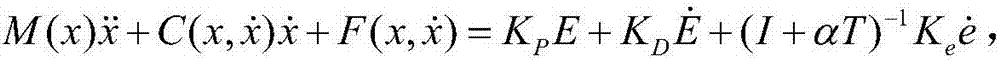

[0043] S1. Establish a mathematical model of a single blade drive motor, that is, deduce the characteristic equation of the motor according to the simplified circuit model of the brushless DC motor, and obtain its transfer function from the characteristic equation. Specifically, the driving motor adopts a brushless DC motor, and its mathematical model is established according to the characteristic equation of the driving motor. In order to ensure the positioning accuracy of the blades of the multi-leaf collimator, the speed, acceleration and number of rotations of the driving motor are precisely controlled, or For the stepping motor to control the number of steps, the control of the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com