Excavator's boom fatigue test program spectrum managing and test loading method

A fatigue test and program spectrum technology, applied in the field of construction machinery, can solve the problems of inability to determine stress and actual state, difficult to directly use for sorting, difficult to sort out load spectrum, etc., to achieve simple and feasible fatigue test, avoid test errors, and ensure reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

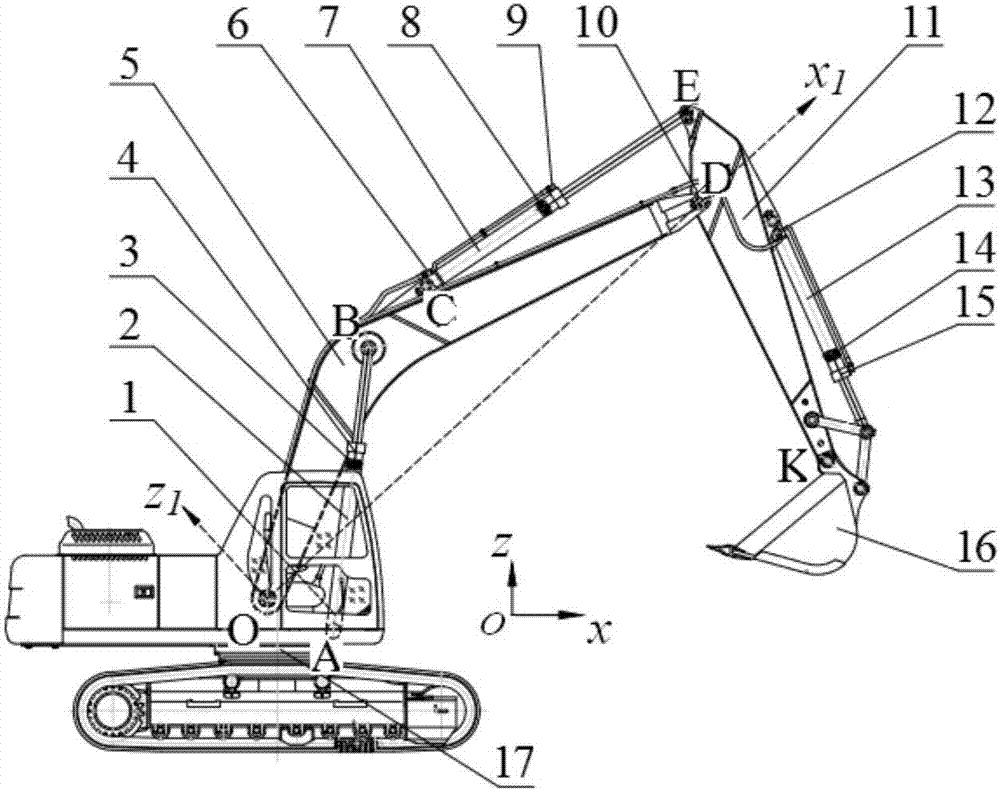

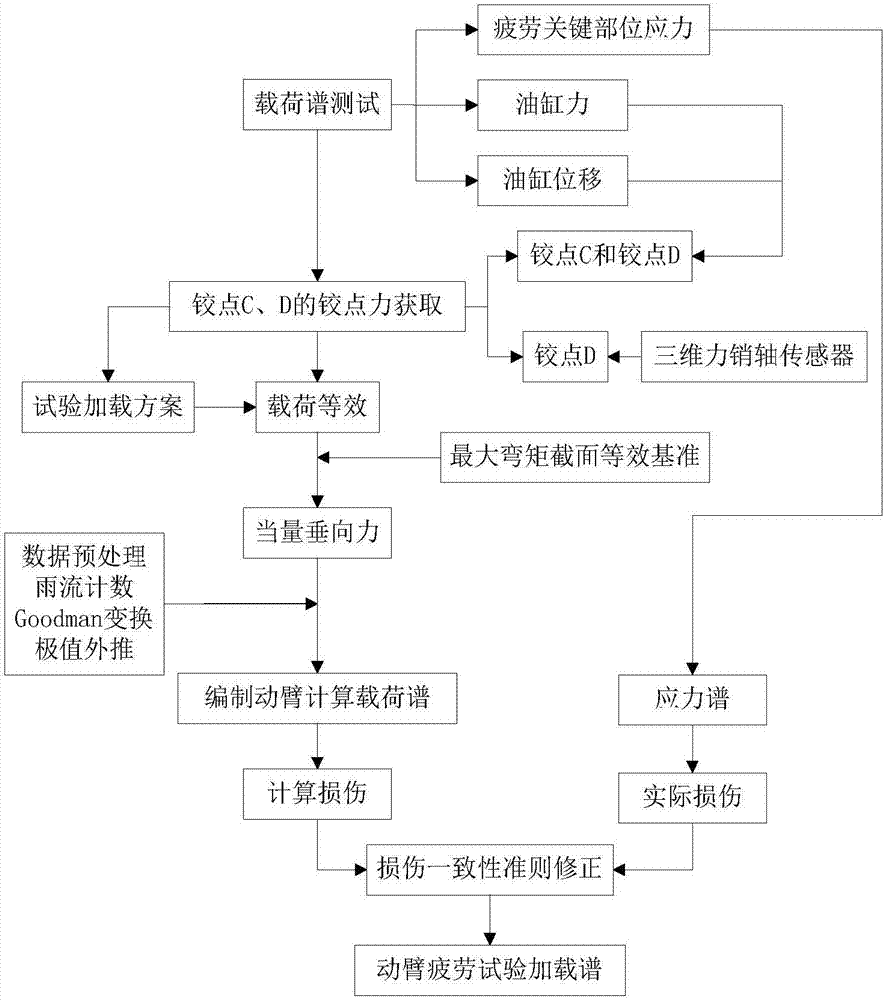

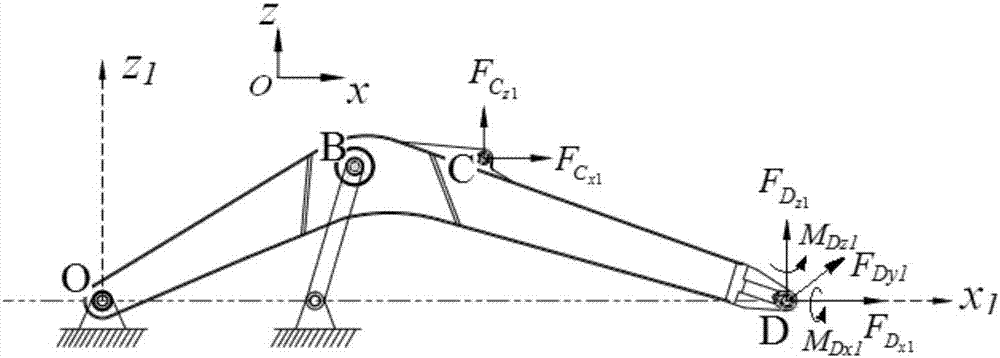

[0055] Comply with the above technical solutions, such as figure 1 As shown in FIG. 3 , in order to make the technical solution of the present invention more clear, the solution will be further described below in conjunction with the accompanying drawings and embodiments.

[0056] Such as figure 1 As shown, the working device of the excavator includes three parts: boom 5 , arm 11 and bucket 16 . The main research object of the present invention is the boom 4, one end of which is hinged with the turntable 17 of the excavator, and the hinge point is marked as point O, and the other end is hinged with the arm 11, and the hinge point is marked as point D; the arm 11 is hinged with the bucket 16 At point K. The boom cylinder 2 is arranged on the lower side of the boom 5, and its two ends are respectively hinged on the turntable 17 and the boom 5, and the hinge points are respectively marked as point A and point B; Click to execute landing action. The stick cylinder 7 is set on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com