Multi-type high-precision planetary roller lead screw pair precision detection device

A planetary roller, precision detection technology, used in measuring devices, optical devices, machine gear/transmission mechanism testing, etc. Problems such as secondary testing to achieve the effect of ensuring parallelism, ensuring test accuracy, and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0026] The object of the present invention is to overcome the deficiencies in the prior art, and provide a planetary roller screw pair accuracy detection device capable of testing multi-type screw pairs with extremely high testing accuracy.

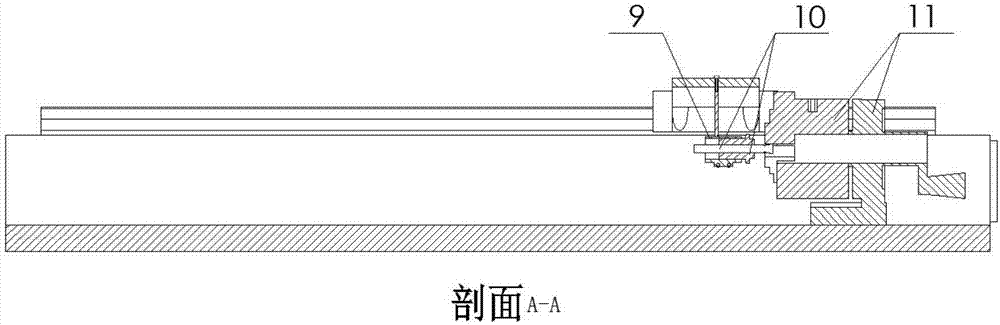

[0027] refer to figure 1 , 2 , 3, a multi-type high-precision planetary roller screw pair accuracy detection device, including: test bench (1); grating ruler (2); reading head (3); nut sleeve guide rod (4); connecting plate (5); Slider (6); Linear guide (7); Lock nut (8); Nut sleeve (9); Roller screw (10.1); Nut (10.2); Two-way positioning handle (11.1); Three-jaw chuck (11.2); display screen (12).

[0028] The punch former (11) is composed of a two-way positioning handle (11.1) and a three-jaw chuck (11.2). The two-way positioning handle (11.1) is installed on the test bench (1); the two-way positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com