Rotary type annular soil-bin test platform braking mechanism

A technology of annular soil tank and braking mechanism, which is applied in the direction of brake actuator, brake type, axial brake, etc., and can solve the problems of inability to brake and stop the rotation of the ring soil tank, low use efficiency, long stop time, etc. problems, to achieve the effect of improving equipment use efficiency, avoiding losses and injuries, and braking quickly and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

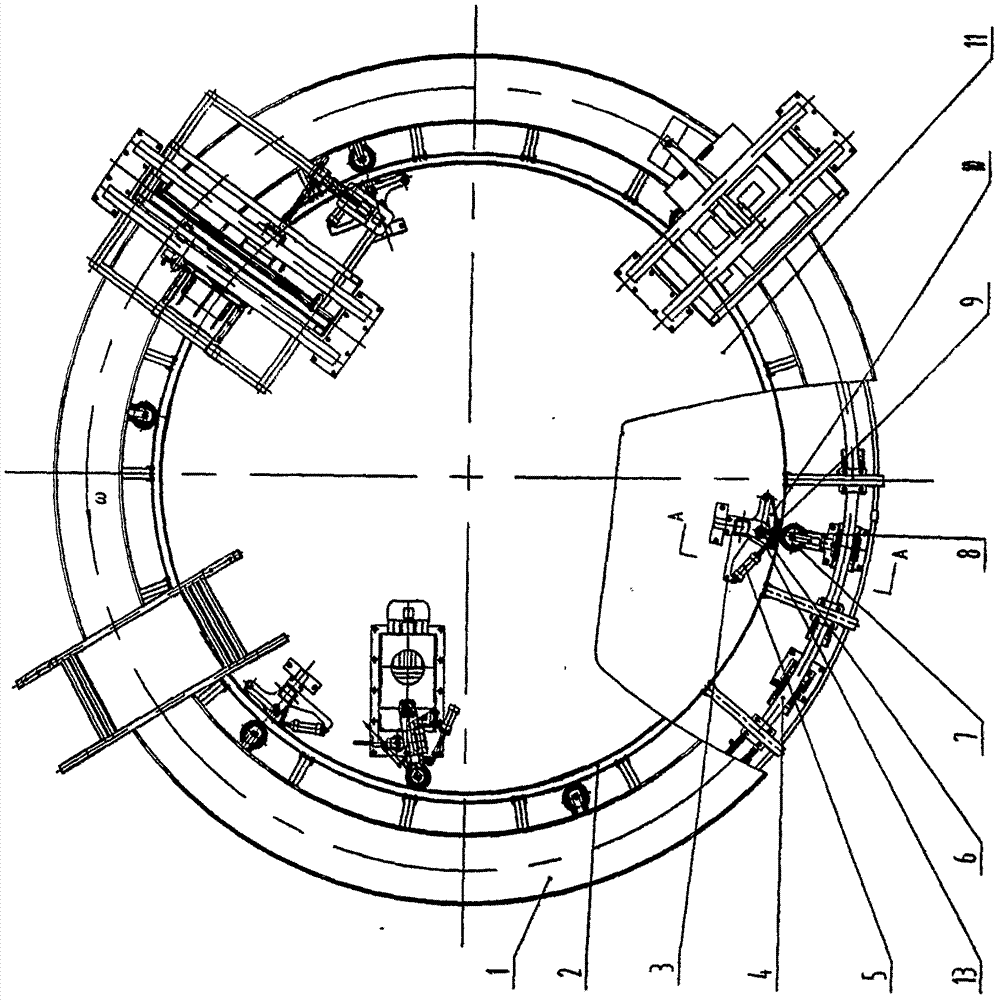

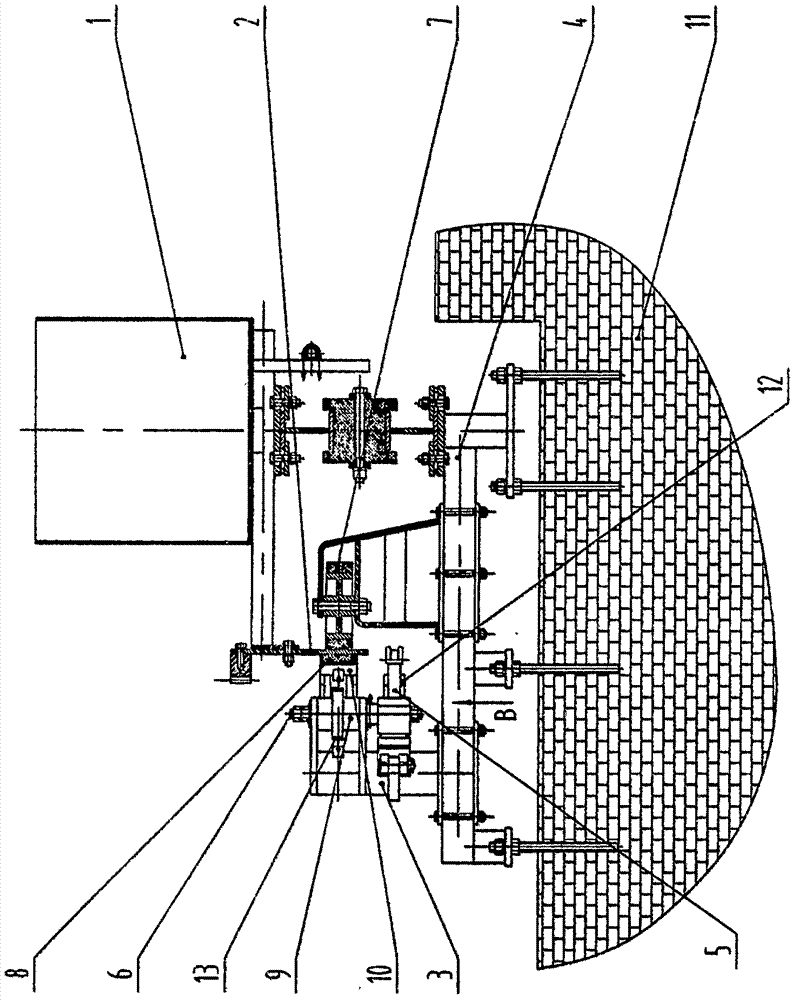

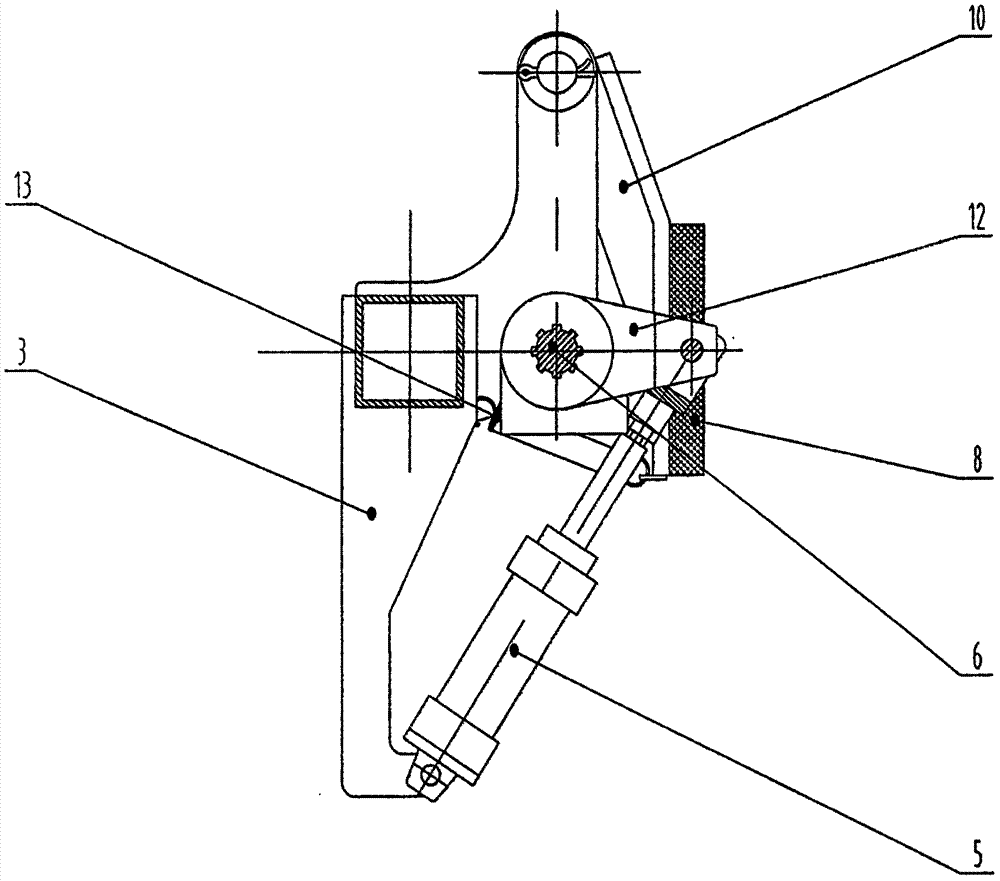

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A rotary annular soil tank test bench braking mechanism, on the base 11, the ring-shaped soil tank 1 can be rotatably installed through the ring track frame 4, and the inner ring gear and the cylindrical cylinder are fixed on the inner wall surface of the ring-shaped soil tank 1 The assembly 2 is equipped with a center positioning support wheel 7 on the annular track frame 4 at the outer part of the circumference of the ring gear and cylinder combination 2, and the center positioning support wheel 7 is combined with the ring gear and the cylinder The outer wall surface of the body 2 is in a contact fit, and the brake frame 3 is fixed on the annular track frame 4, which is located at the inner side of the inner ring gear and the cylinder assembly 2 and the opposite position of the central positioning support wheel 7. The brake drive cylinder 5 and the fri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com