Method for controlling roadway deformation by presplitting blasting pressure release of base angle of roadway protection coal pillar

A technology of pre-splitting blasting and coal pillars, which is applied in the field of pre-splitting blasting at the bottom corner of coal pillars to control roadway deformation. It can solve the problems of interfering with the production of the working face, labor and time, and construction difficulties, and save manpower and materials. Cost, improved stress environment, simple construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

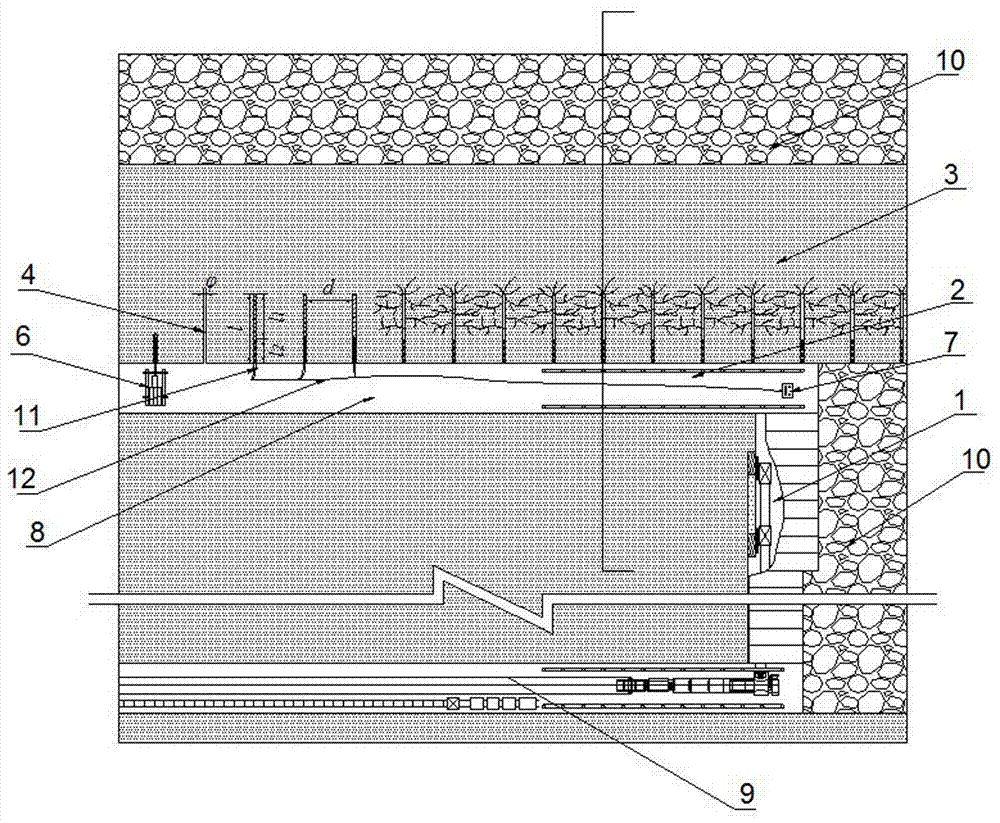

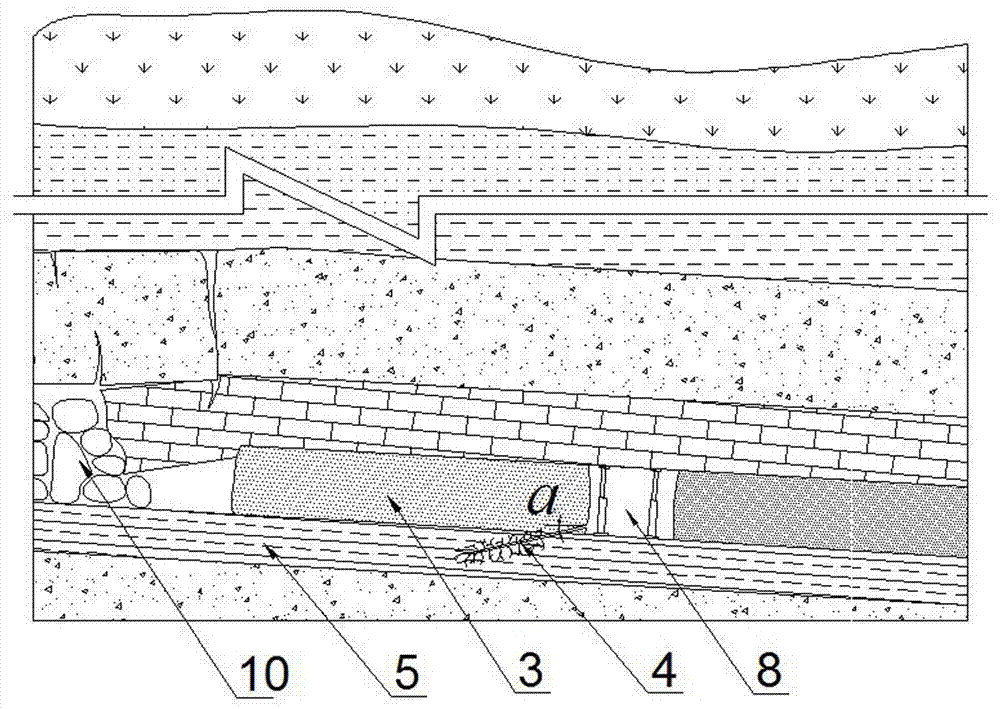

[0022] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

[0023] Such as figure 1 , figure 2 As shown, there are all kinds of mechanical equipment and equipment required for comprehensive mechanized coal mining in the coal mining face 1, the return air lane 8 is the recovery roadway through which the dirty air in the mine ventilation system passes, and the transportation lane 9 is the mining roadway used in the mine transportation system. In the mining roadway for coal transportation and material transportation, the goaf 10 is the hollow area left after the coal seam is mined. The roadway coal pillar 3 is the unmined part of the coal body that supports and isolates the roadway. The method for controlling the deformation of the roadway by pre-splitting blasting at the bottom corner of the roadway coal pillar proposed by the present invention for pressure relief, the specific steps are as follows:

[0024] A row ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com