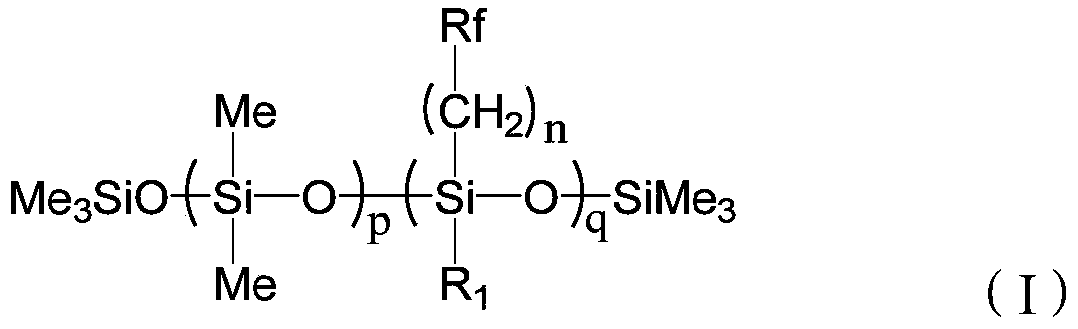

Perfluoroether-based polysiloxane and its preparation method and application

A technology of perfluoroether-based dichlorosilane and polysiloxane, which is applied in the directions of base materials, lubricating compositions, additives, etc., achieves the effects of easy free rotation, easy control, and good viscosity-temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

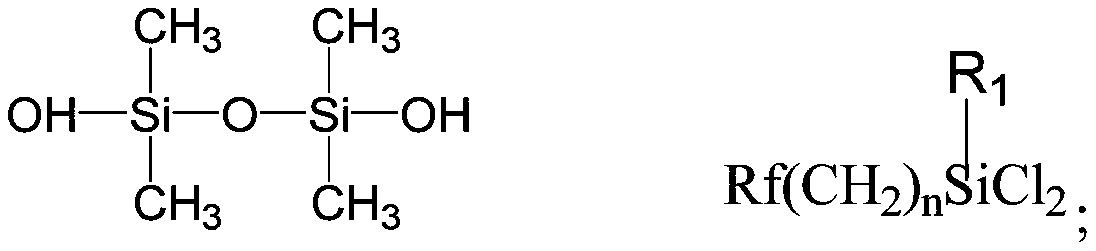

Embodiment 1

[0044] Add 500 mL of m-xylene hexafluoride and 0.25 mol of triethylamine into a four-neck flask, stir and mix evenly, heat to 60°C, and add 0.1 mol of perfluoroether-based dichlorosilane and 150 mL of m-xylene hexafluoride dropwise at the same time and the mixed solution of 0.105mol of disiloxanediol and 150mL of methyl ethyl ketone, after 80 minutes of dripping, the reaction mixture was stirred for 30 minutes; the reactant was washed with water to remove the by-product hydrochloride, separated The organic layer was distilled under reduced pressure to obtain perfluoroether cyclotrisiloxane.

[0045]Under the protection of an inert gas, mix 0.3mol octamethylcyclotetrasiloxane, 0.1mol decamethyltetrasiloxane, and 0.0003mol potassium hydroxide, raise the temperature to 140°C, and add 0.1mol perfluoroether cyclotrisiloxane dropwise. Siloxane, after 2 hours of dripping, continue to react for 1 hour, neutralize with 0.00012mol phosphoric acid after the reaction, and then vacuum remo...

Embodiment 2

[0049] Add 500 mL of m-xylene hexafluoride and 0.22 mol of dimethylaniline into a four-neck flask, stir and mix evenly, heat to 80°C, and at the same time add 0.1 mol of perfluoroether dichlorosilane and m-xylene hexafluoride dropwise 150 mL of the mixed solution, and the mixed solution of 0.105 mol of disiloxanediol and 150 mL of methyl ethyl ketone, dripped for 60 minutes, and after the dropping, stirred the reaction mixture for 30 minutes; The organic layer was taken out and subjected to vacuum distillation to obtain perfluoroether-based cyclotrisiloxane.

[0050] Under the protection of an inert gas, mix 0.2mol DMC, 0.05mol dodecamethylpentasiloxane, and 0.0015mol potassium hydroxide, raise the temperature to 120°C, add 0.2mol perfluoroether cyclotrisiloxane dropwise, drop for 4 hours After completion, the reaction was continued for 3 hours. After the reaction, it was neutralized with 0.0015mol hydrochloric acid, and then vacuum removed at -0.099Mpa at 200°C for 1 hour to ...

Embodiment 3

[0053] Add 500 mL of m-xylene hexafluoride and 0.3 mol of pyridine into a four-neck flask, stir and mix evenly, heat to 30°C, and simultaneously add 0.1 mol of perfluoroether-based dichlorosilane and 150 mL of m-xylene hexafluoride dropwise. solution, and a mixed solution of 0.1 mol of disiloxanediol and 150 mL of methyl ethyl ketone, dripped over 150 minutes, and stirred the reaction mixture for 30 minutes after dripping; washed the reactant with water to remove by-product hydrochloride, and separated the organic layer Distill under reduced pressure to obtain perfluoroether-based cyclotrisiloxane.

[0054] Under the protection of inert gas, mix 0.2mol octamethylcyclotetrasiloxane, 0.001mol decamethyltetrasiloxane, and 0.00025mol tetramethylammonium hydroxide, raise the temperature to 90°C, and add 0.1mol perfluoroether dropwise Cyclotrisiloxane, after 3 hours of dripping, continue to react for 2 hours, after the reaction, heat to 160°C for 0.5h, decompose the catalyst, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com