Bag body shaping device for pure electric shaping packer and shaping method

A pure electric technology for plastic packaging, which is applied in the field of tea packaging and bag body shaping devices. It can solve the problems of single tea packaging bag shaping methods, achieve flexible and diverse shaping methods, speed up packaging, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention takes the factory building of Xing'an Metal Co., Ltd., Anxi County, Fujian Province as the specific implementation location, and provides the following specific examples.

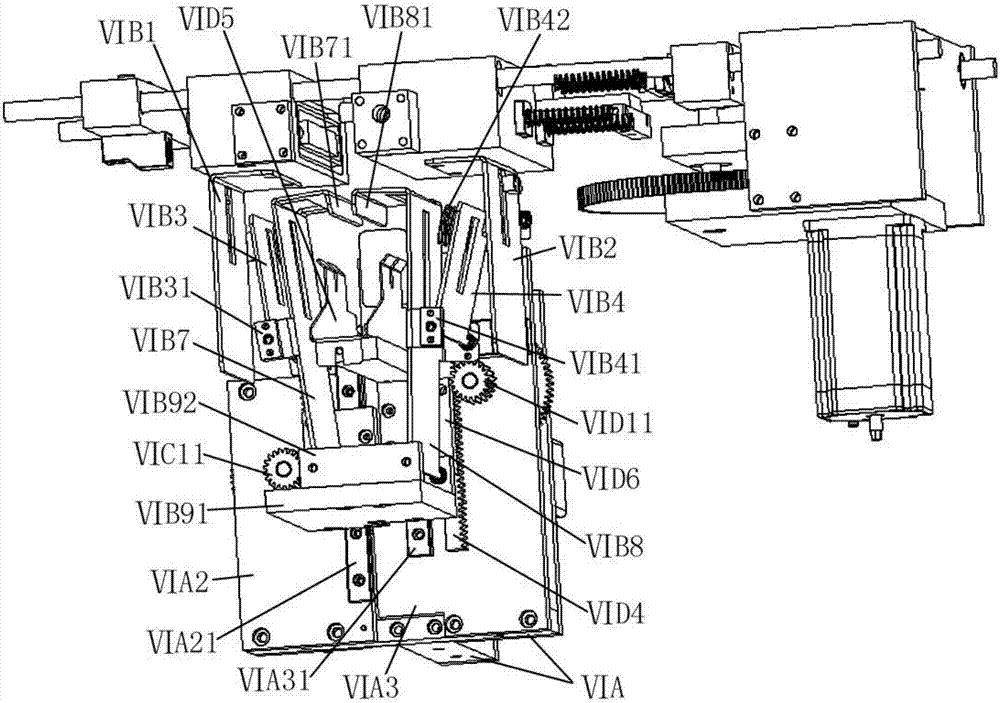

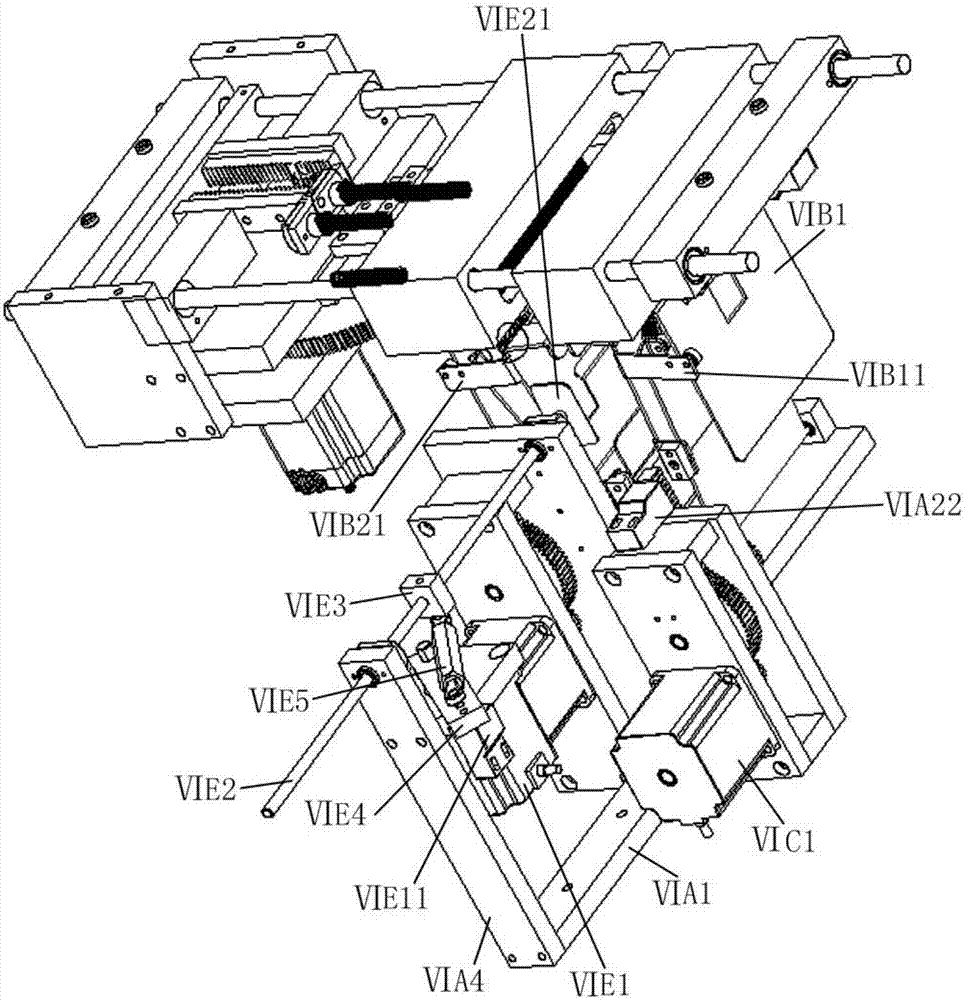

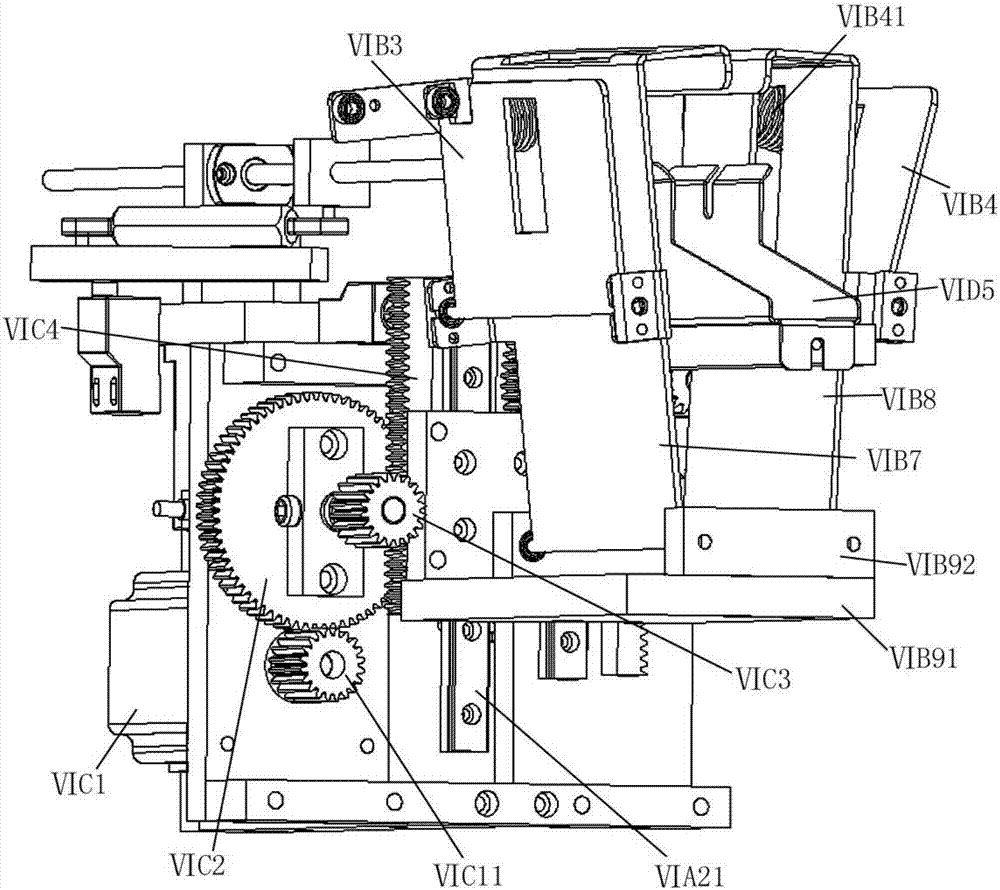

[0054] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a bag body shaping device applied in a pure electric shaping packaging machine is composed of an aluminum main board, an aluminum material hanging wallboard, a pull-down shaping mechanism, a drop / lift drive transmission mechanism, an upward shaping mechanism, and a material pushing mechanism. The mechanism composition is characterized in that the aluminum main board VIA includes a horizontal horizontal plate and a horizontal vertical plate VIA1, the horizontal horizontal plate is horizontally left and right, the horizontal vertical plate VIA1 is horizontally front and rear, and the front plate of the horizontal vertical plate VIA1 The end is fastened to the middle of the rear side of the horizontal horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com