Sulfur tail gas purification process for direct discharge after treatment

A treatment process and process technology, applied in the field of sulfur tail gas treatment process, to achieve significant desulfurization effect, ensure absorption effect, and reduce steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

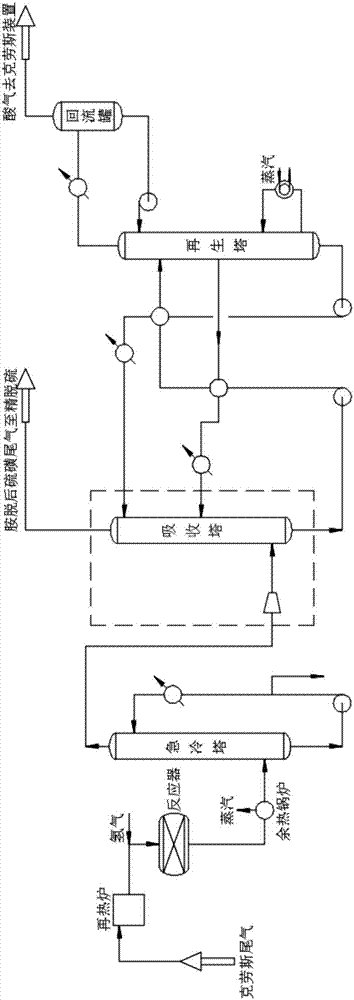

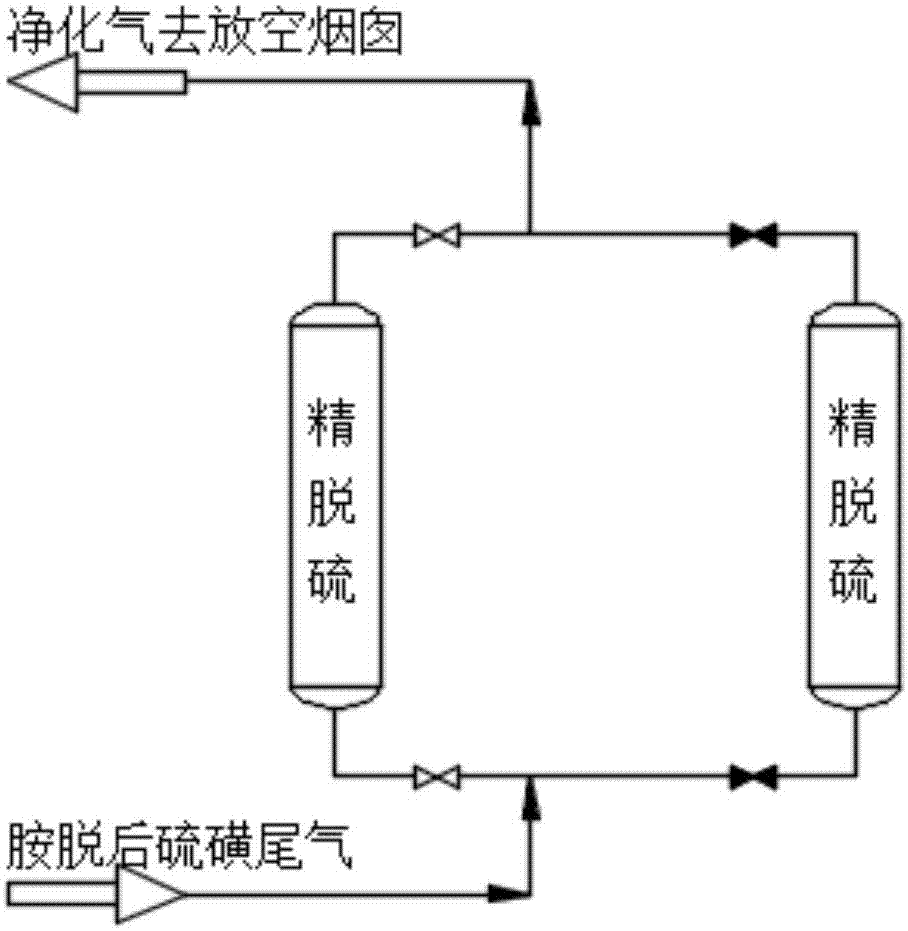

[0037] A sulfur tail gas treatment process that can be directly discharged after treatment, aimed at removing CO from raw gas with amines 2 When the content is not higher than 10% (mol / mol), based on the existing Super-SCOT process, the process is as follows figure 1 As shown, wherein: a compressor is installed between the quenching tower and the absorption tower, and the tail gas after exiting the quenching tower is pressurized to 0.15MPa by the compressor and then enters the lower part of the absorption tower. Contact for amine removal, the number of absorption stages in the absorption tower is 22 actual trays; the tail gas after amine removal is discharged from the top of the absorption tower and sent to the fine desulfurization system; the rich liquid after amine removal is discharged from the bottom of the absorption tower and sent to the upper part of the regeneration tower to be Stripping to semi-lean liquid; part of the semi-lean liquid is extracted from the 1-3 layers...

Embodiment 2

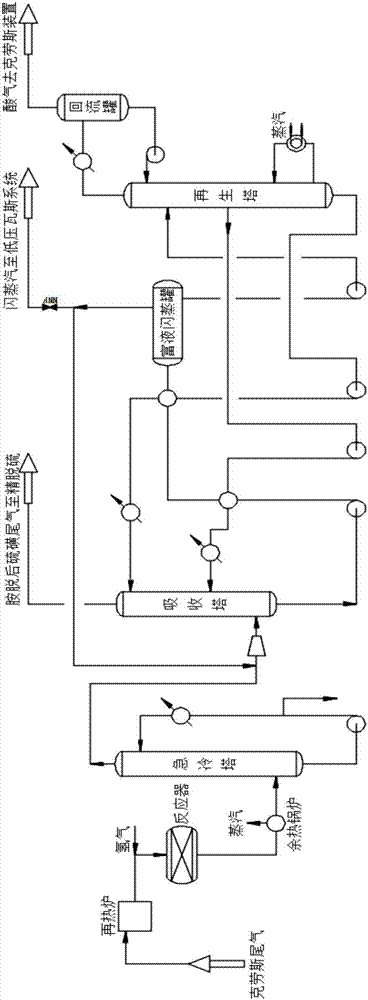

[0042] A sulfur tail gas treatment process that can be directly discharged after treatment, aimed at removing CO from raw gas with amines 2 The content is higher than 10% (mol / mol), based on the existing Super-SCOT process, the process is as follows figure 2 As shown, wherein: a compressor is set between the quenching tower and the absorption tower, and a rich liquid flash tank is set between the absorption tower and the regeneration tower; the tail gas after the quenching tower is pressurized to 0.15Mpa by the compressor and then enters the absorption tower In the lower part, the desulfurization solvent is reversely contacted with the desulfurization solvent in the absorption tower under pressurized state to carry out deamination, and the number of absorption stages in the absorption tower is 20 actual trays; the exhaust gas after deamination is discharged from the top of the absorption tower and sent to the fine desulfurization system; The rich liquid after amine removal is...

Embodiment 3

[0046] A sulfur tail gas treatment process that can be directly discharged after treatment, for sulfur tail gas with a COS content higher than 50ppm (mol / mol), based on the existing Super-SCOT process, the process is as follows figure 1 As shown, wherein: a compressor is installed between the quenching tower and the absorption tower, and the tail gas after leaving the quenching tower is pressurized to 0.20MPa by the compressor and then enters the lower part of the absorption tower. Contact for amine removal, the number of absorption stages in the absorption tower is 25 actual trays; the tail gas after amine removal is discharged from the top of the absorption tower and sent to the fine desulfurization system; the rich liquid after amine removal from the bottom of the absorption tower is sent to the upper part of the regeneration tower to be Stripping to semi-lean liquid; part of the semi-lean liquid is extracted from the 1-3 layers above the middle layer of the regeneration tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com