Device for automatic cable disengaging of underground robots

A technology for underwater robots and de-cables, which is applied in the direction of connection/disconnection of connecting devices, and can solve the problems of cable winding, underwater robot cable winding, and complex underwater working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

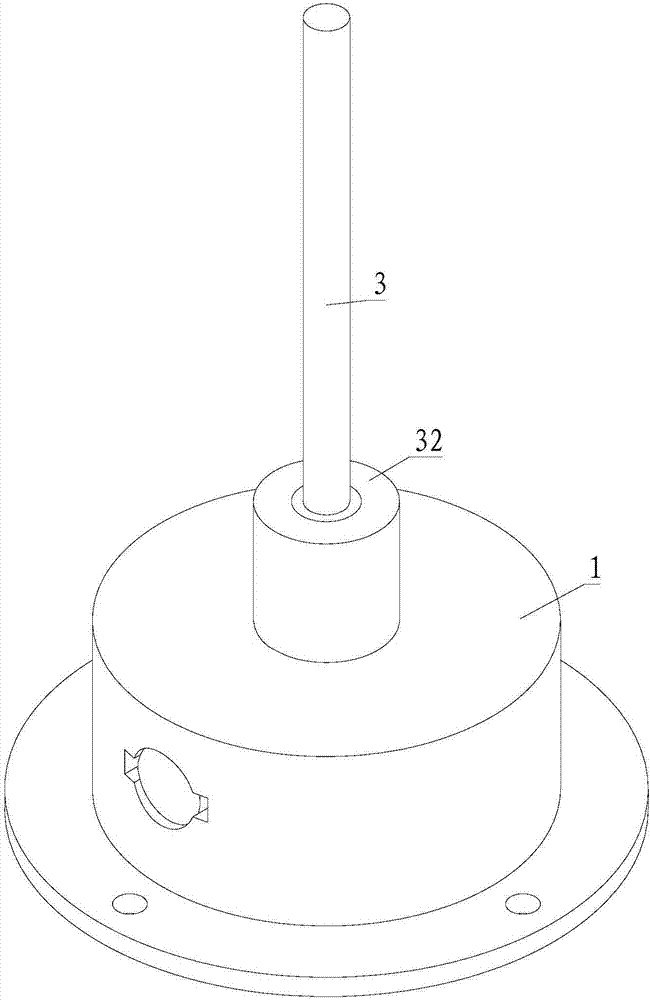

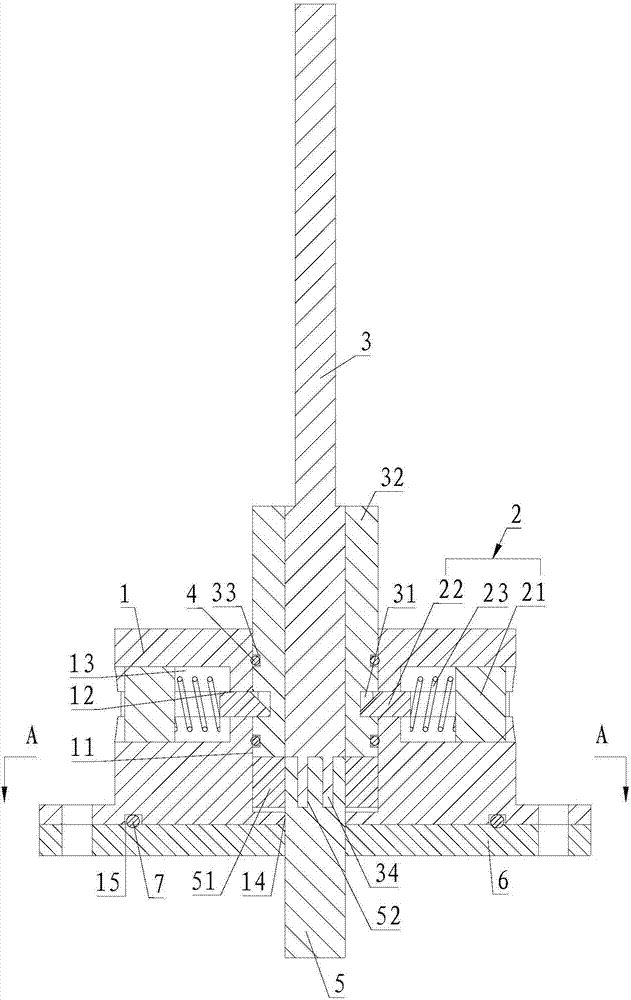

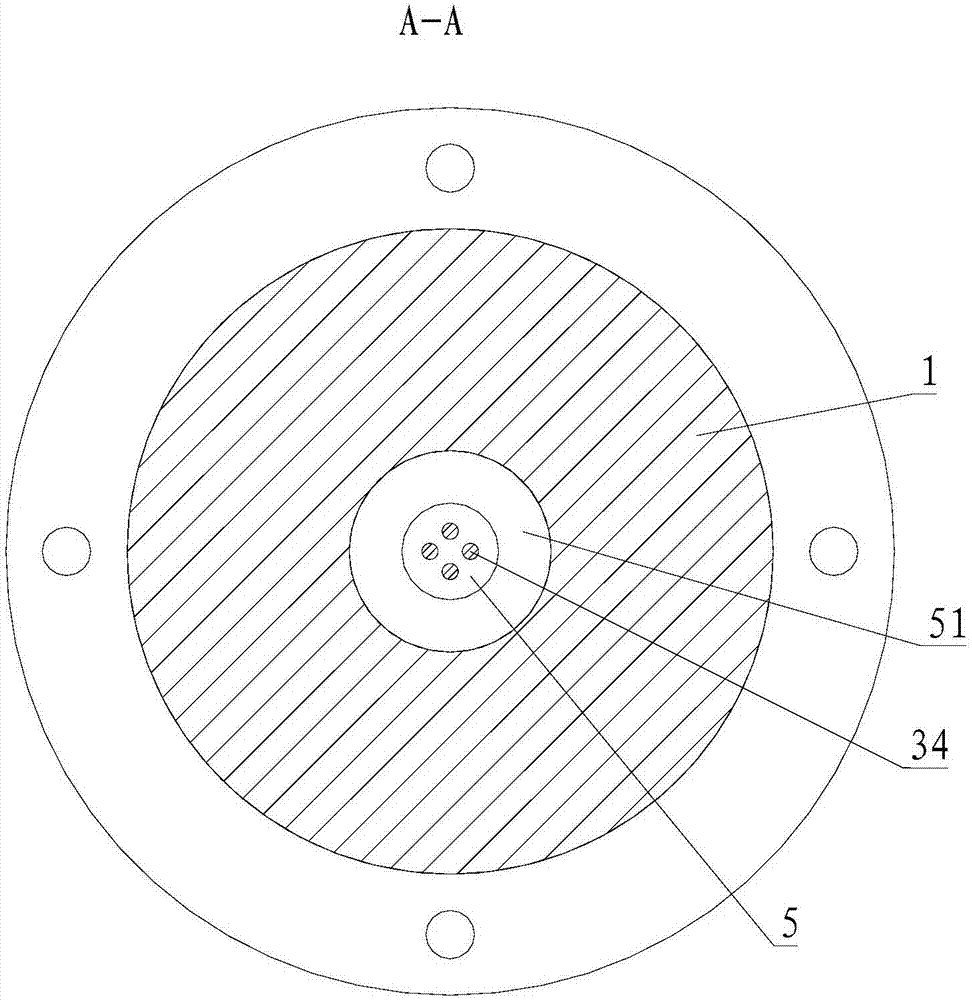

[0045] Please refer to Figure 1 to Figure 5 , The first embodiment of the present invention is:

[0046] An automatic cable-removing device for an underwater robot includes a base 1 and a cable-removing assembly 2. The upper surface of the base 1 is provided with a first groove 11 extending downward, and the inner side wall of the first groove 11 extends from the inside. A first through hole 12 and a second through hole 13 are sequentially opened to the outside. The diameter of the first through hole 12 is smaller than the diameter of the second through hole 13, and the cable release assembly 2 includes a slider 22 and a linear movement Drive power member 21 and spring 23, the cross-sectional shape of the slider 22 is T-shaped, one end is a big end, and the other end is a small end, the linear motion driving power member 21 is connected to the big end of the slider 22 , The linear motion driving power member 21 is fixed in the second through hole 13, the small end of the slider...

Embodiment 2

[0047] Please refer to Figure 1 to Figure 5 , The second embodiment of the present invention is:

[0048] An automatic cable removal device for an underwater robot, based on the first embodiment, further includes a first cable 3 and a first sealing ring 4, and the end of the first cable 3 is inserted into the first groove 11 Wherein, the outer circular surface of the end of the first cable 3 is provided with a second groove 31, the height of the second groove 31 is adapted to the height of the slider 22, and the slider 22 is embedded in In the second groove 31, the shape of the bottom surface of the second groove 31 is a plane or an annular surface; preferably, a first reinforcing connector 32 is integrally provided on the end of the first cable 3, and The outer shape of the first reinforcing connecting member 32 is a circular ring body, the first reinforcing connecting member 32 is inserted into the first groove 11, and the second groove 31 is provided in the first reinforcing...

Embodiment 3

[0049] Please refer to Figure 1 to Figure 5 , The third embodiment of the present invention is:

[0050] An automatic cable removal device for an underwater robot, on the basis of the second embodiment, further includes a second cable 5, the bottom of the first groove 11 is provided with a third through hole 14, and the end of the second cable 5 The part passes through the third through hole 14 and is electrically connected to the end of the first cable 3; the end of the first cable 3 is provided with a conductive pin 34 extending downward, and the end of the second cable 5 There is a third groove 52 extending downward from the part, and the conductive pin 34 is inserted into the third groove 52; the end of the second cable 5 is integrally provided with a second reinforcing connector 51, The outer shape of the second reinforcing connecting member 51 is a circular ring body, and the second reinforcing connecting member 51 is fixedly connected to the bottom of the first groove 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com