Three-dimensional point cloud model-based monocrystalline silicon rod boundary dimension measurement method

A single crystal silicon rod, three-dimensional point cloud technology, applied in the direction of measuring devices, image data processing, instruments, etc., can solve the problems of troublesome processing procedures, easy deviation of measurement from the real value, etc., achieve efficient quality assurance, realize automatic measurement, complex low degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

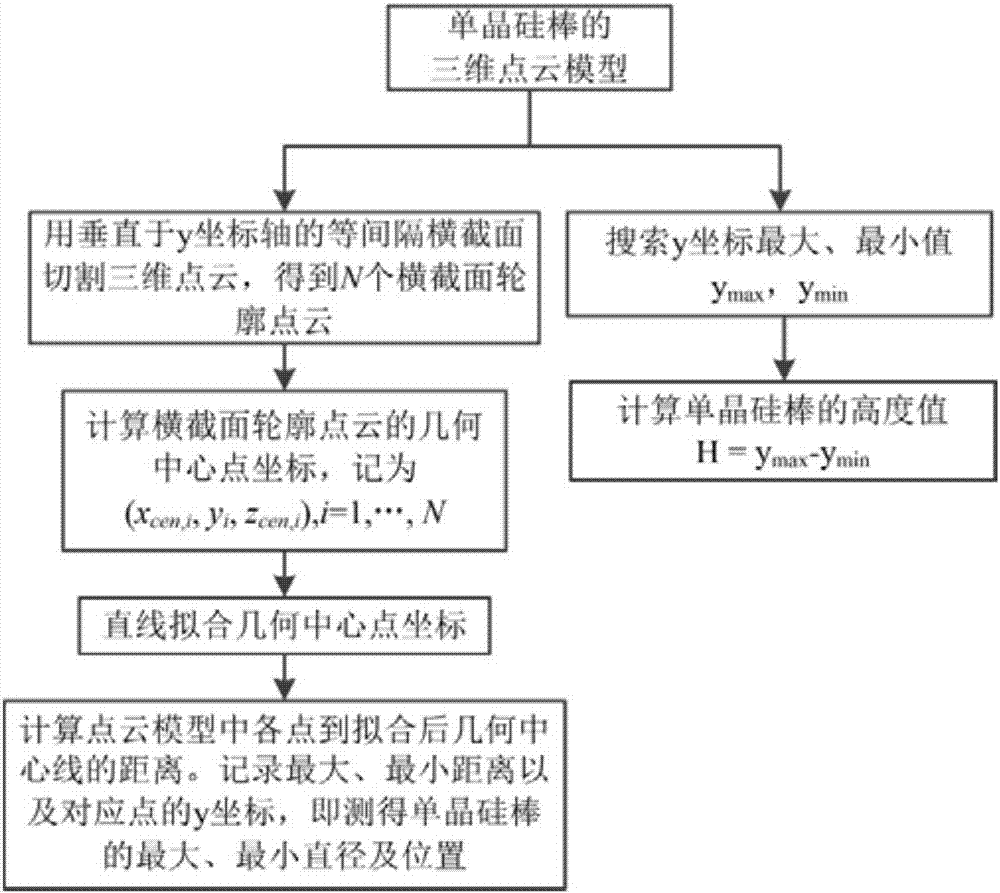

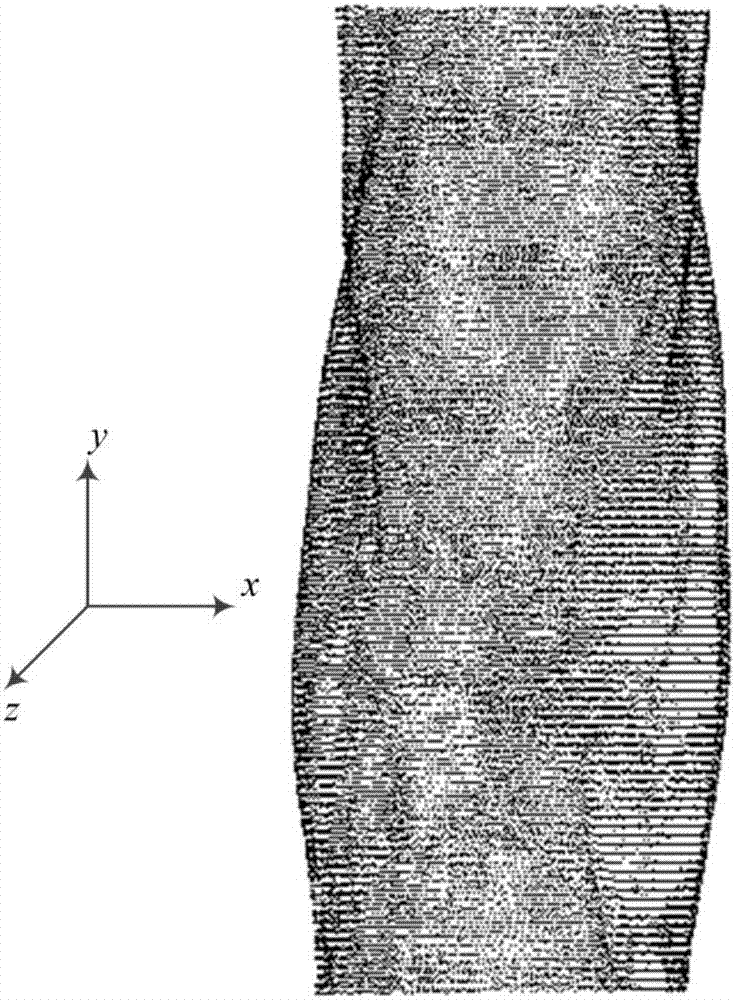

[0041] (1) if figure 2 As shown, perpendicular to the height direction (y-coordinate direction) of the three-dimensional point cloud model of the single crystal silicon rod, the point cloud is layered at intervals of 4 mm. The y coordinate value of the i-th layer y i 2mm+i×4mm, the y coordinate is in y i The points within the range of ±2mm belong to the same layer of contour point cloud, and a total of N layers of contour line point cloud are obtained. After this processing, it is considered that the contour line point cloud of the same layer has the same y coordinate.

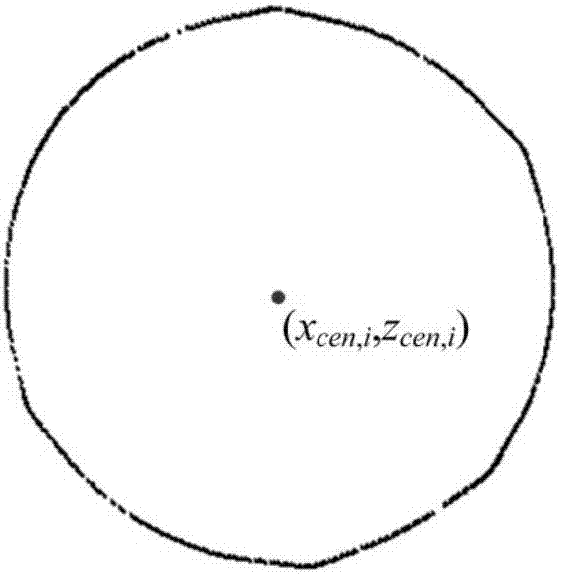

[0042] (2) image 3 is the contour point cloud of the i-th layer, and the geometric center coordinates of the contour point cloud of this layer are calculated by formula (1), where M i is the number of points in the contour line of this layer, (x j ,z j ) is any point in the contour point cloud of this layer. The calculated center coordinates (x cen,i ,z cen,i )Such as image 3 Indicated by the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com