Determination method for optimal illumination intensity and luminous environment regulation method in commercialized enclosed type leaf vegetable production system, and system

A technology of light intensity and production system, applied in horticultural methods, botanical equipment and methods, agricultural machinery and equipment, etc., can solve problems such as constraints, high energy consumption, and low efficiency, and achieve the effect of reducing blind investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This example provides a method for determining the optimal light intensity in a commercial closed-type leaf vegetable production system. In the following method, the optimal water, fertilizer, and carbon dioxide concentration conditions are used, and are set to be fixed during the control process.

[0046] Specifically:

[0047] S1. Obtain the market sales price P of the leafy vegetables to be planted in the commercial closed leafy vegetable production system;

[0048] S2. Let the light intensity in the production system be L i ; Assuming that the number of vegetable planting days is j, and j=1,2,3...h-1,h; calculate the daily effective yield of vegetables from the planting day j=1 to the harvest day j=h according to the formula I , the effective yield Y of vegetables on the hth day Li,h That is, the effective yield Y (L i );

[0049]

[0050] In the formula I, Y Li,j Represents the light intensity L i The effective yield of vegetables on the jth day under the ...

Embodiment 2

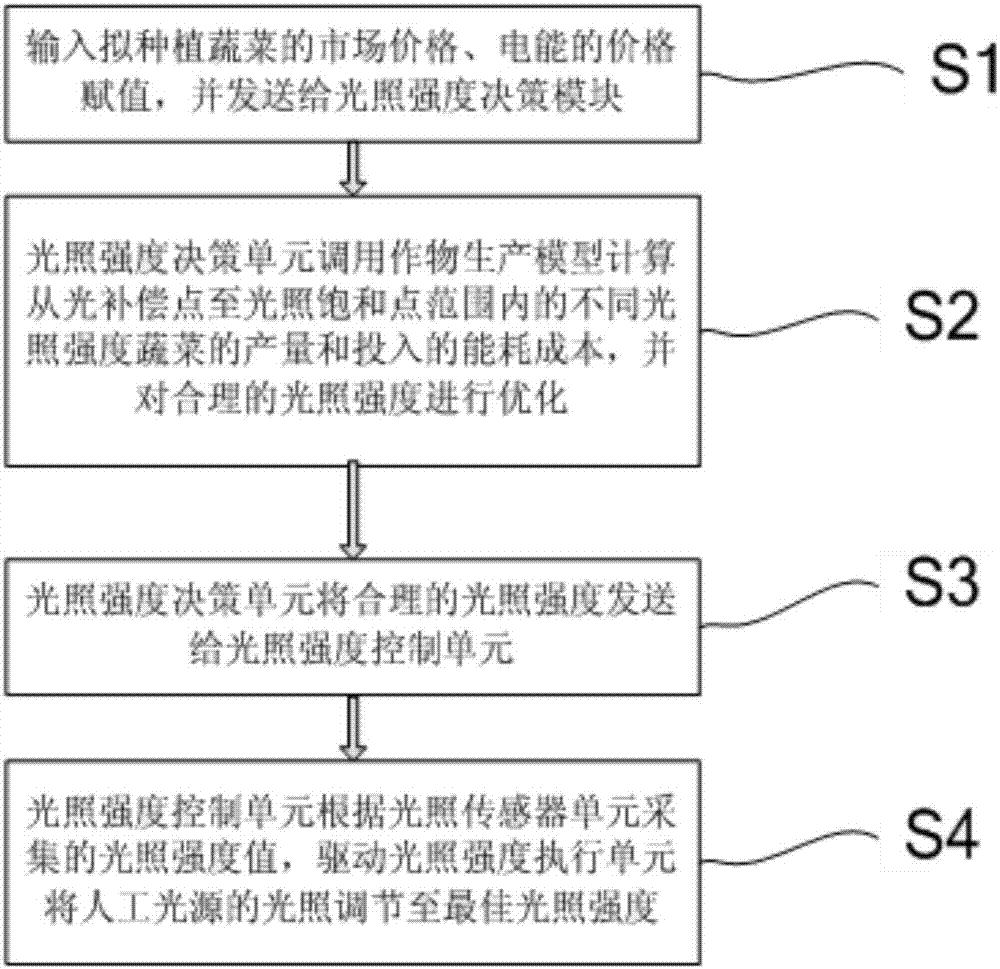

[0080] This embodiment provides a light environment control device for a commercialized closed leaf vegetable production system, its structure is as follows: image 3 As shown, it includes: an illumination sensor unit 1 , an illumination intensity optimization decision-making unit 2 , an illumination intensity control unit 3 , and an illumination intensity execution unit 4 .

[0081] The illumination sensor unit 1 consists of three illumination sensors distributed in different positions of the production system to collect the illumination intensity of the artificial light source in the system, average the illumination intensity collected by different sensors and send it to the illumination intensity control unit 3 .

[0082] The light intensity optimization decision-making unit 2 simulates the effective output of vegetables under different light intensities in combination with the vegetable output estimation model according to the market price of vegetables to be planted and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com