Dual-drying-chamber hot air circulating drying box

A technology of hot air circulation oven and drying chamber, which is applied in drying, drying machines, lighting and heating equipment, etc., and can solve problems such as affecting the drying effect, drying temperature balance of undried objects, endangering life, property safety, etc. , to avoid adverse consequences and overcome uneven drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

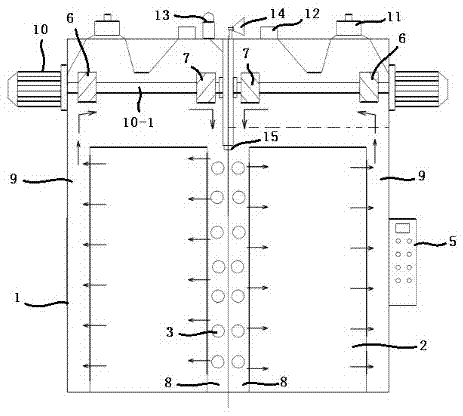

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

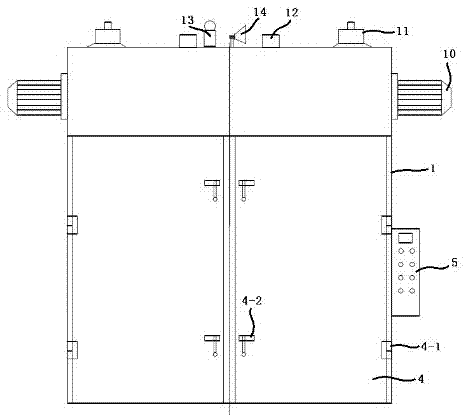

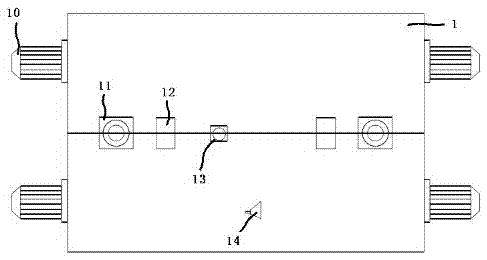

[0015] Such as Figure 1~3 Shown is a double drying chamber hot air circulation oven of the present invention, mainly comprising a box body 1, which is provided with a thermostat 11, a solenoid valve 13 and an alarm 14; , One side of the box body 1 is provided with a PLC controller 5 . The box body 1 is made of stainless steel square tube and stainless steel plate, and is divided into inner and outer layers. There is an insulation layer between the two layers of stainless steel plates, and the insulation layer is filled with refractory fiber insulation materials. According to the rated temperature required by heat treatment and The heat loss of the oven is used to determine the thickness of the insulation layer.

[0016] Such as image 3 Among them, a drying chamber 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com