Heat pump vacuum coupling far infrared drying device

A technology of far-infrared drying and vacuum drying oven, which is applied in the direction of heating device, drying gas arrangement, and drying solid materials without heating. It can solve the problems of slow drying rate, low moisture content of dried products, and reduced heat transfer coefficient. To achieve the effect of improving the heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

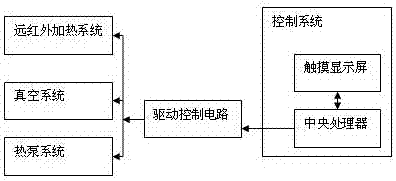

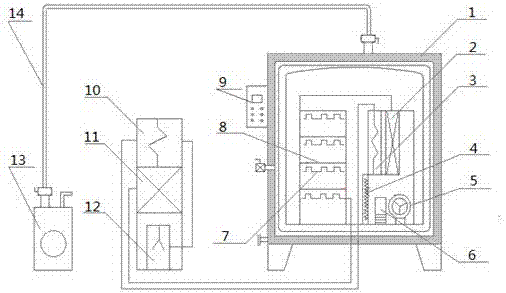

[0017] Such as figure 1 with figure 2 As shown, the present invention includes a sealed vacuum drying box body 1, a heat pump system for heating the vacuum drying box body 1, a vacuum system for evacuating the vacuum drying box, a circulating convection fan 5, a water storage box 6, and A control system 9 that controls the start and stop of the above components;

[0018] The vacuum drying oven body 1 is provided with a multi-layer shelf 8 and a heating coil 7 horizontally, and the heating coil 7 is uniformly arranged in a disc shape under each layer of the shelf 8; the heating coil 7 is arranged The environmentally-friendly refrigerant at a suitable temperature circulates during the drying process. The working fluid flowing in the heating coil 7 provides heat for drying of the material. The uniform disc configuration will uniformly increase the temperature of the material on the shelf 8 and increase Improve drying uniformity and drying efficiency.

[0019] The heat pump system i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com