Eccentric butterfly valve

An eccentric butterfly valve and valve body technology, which is used in lift valves, valve devices, engine components, etc., can solve the problems of easy wear of the sealing structure, safety accidents, leakage, etc., and achieve the effect of avoiding jamming, improving service life and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

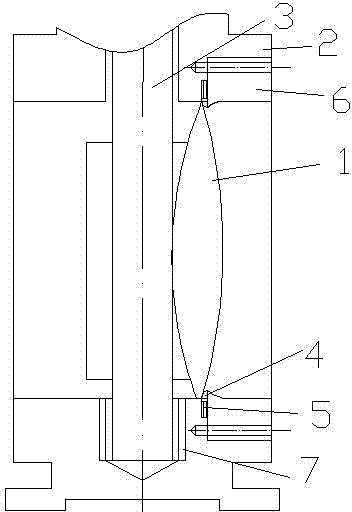

[0025] as shown in the picture 1 An eccentric butterfly valve shown, including a butterfly plate 1 , valve body 2 , stem 3 , sealing ring 4 , spring group 5 ,M 6 , water guide bearing 7 , the stem 3 through the valve body 2 The flow channel is installed in the valve body 2 on, the stem 3 plate mounted on 1 , the stem 3 The bottom is equipped with a water guide bearing 7 , the stem 3 The middle part is installed with a disc plate 1, The deck 1 Set in the runner, the disc 1 Including mounting holes and convex body, the disc is located in the 1 The mounting hole on the stem mounts the 3 above, the axis line of the mounting hole, the disc plate 1 The vertical centerline of the convex body does not intersect the center line of the valve flow channel, the shape of the convex body is circular, and the top vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com