Steering mechanism of three-wheel tractor

A technology for steering mechanisms and tractors, applied in the direction of fluid steering mechanisms, etc., can solve the problems of reduced operability and reliability, small stiffness of steering mechanisms, and large axial dimensions, so as to improve radial force conditions and force conditions , the effect of small axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

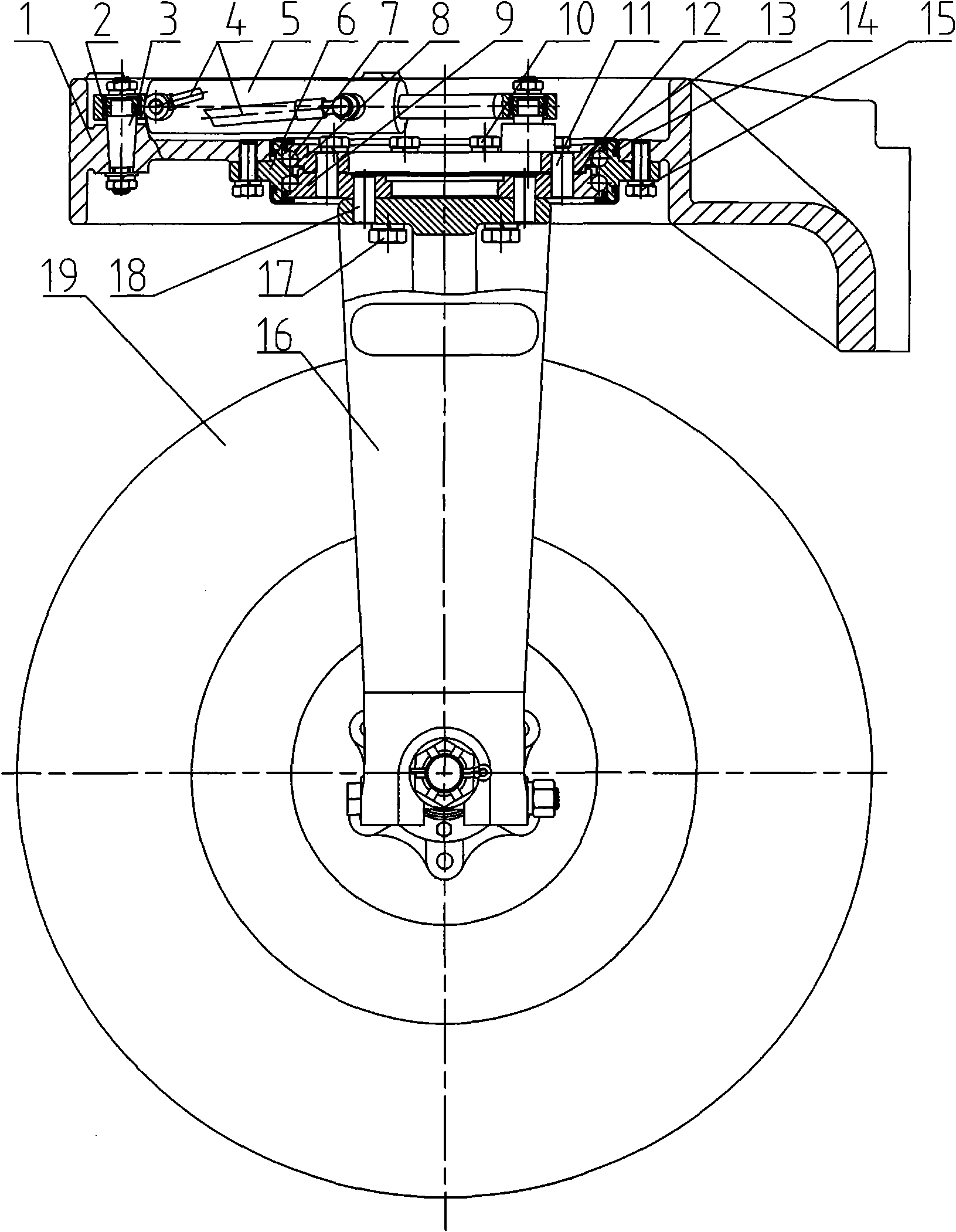

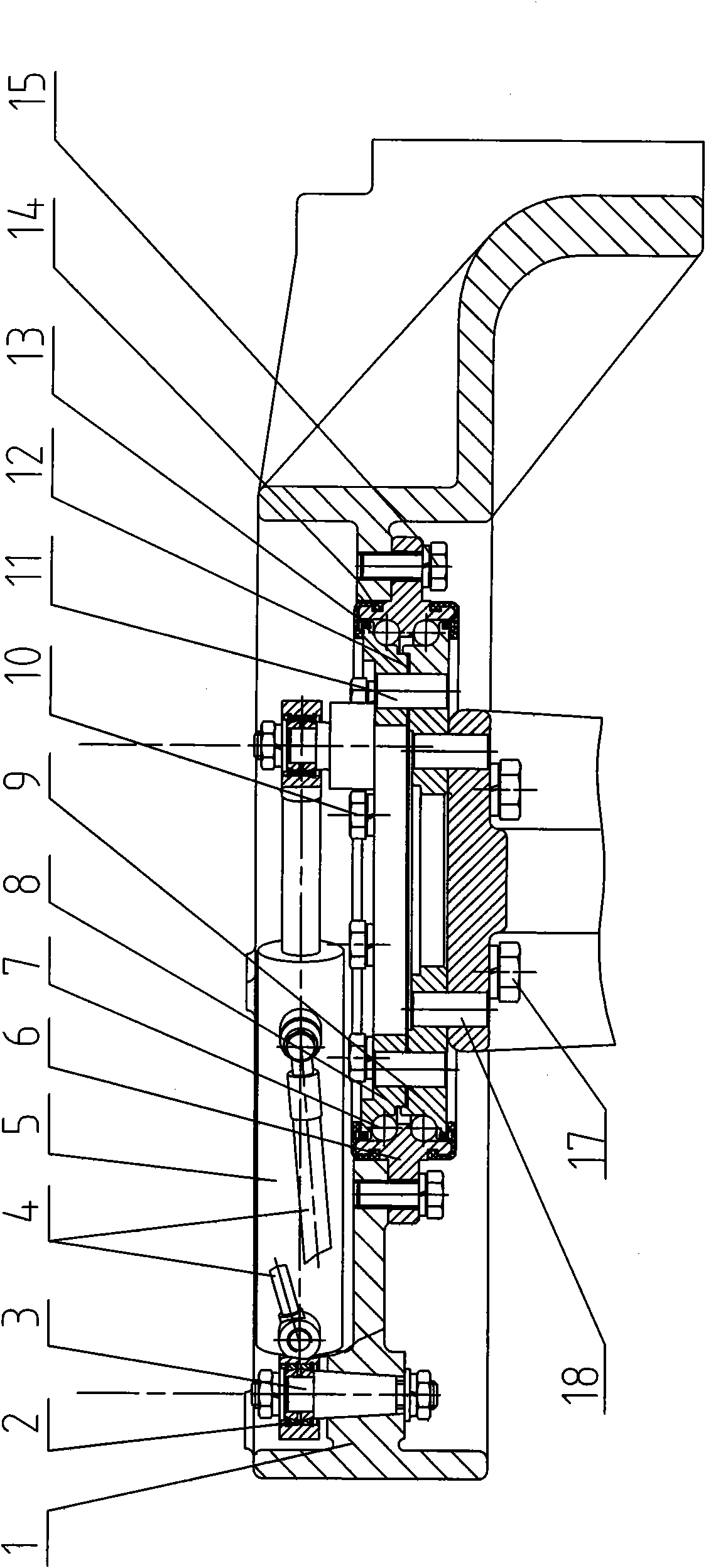

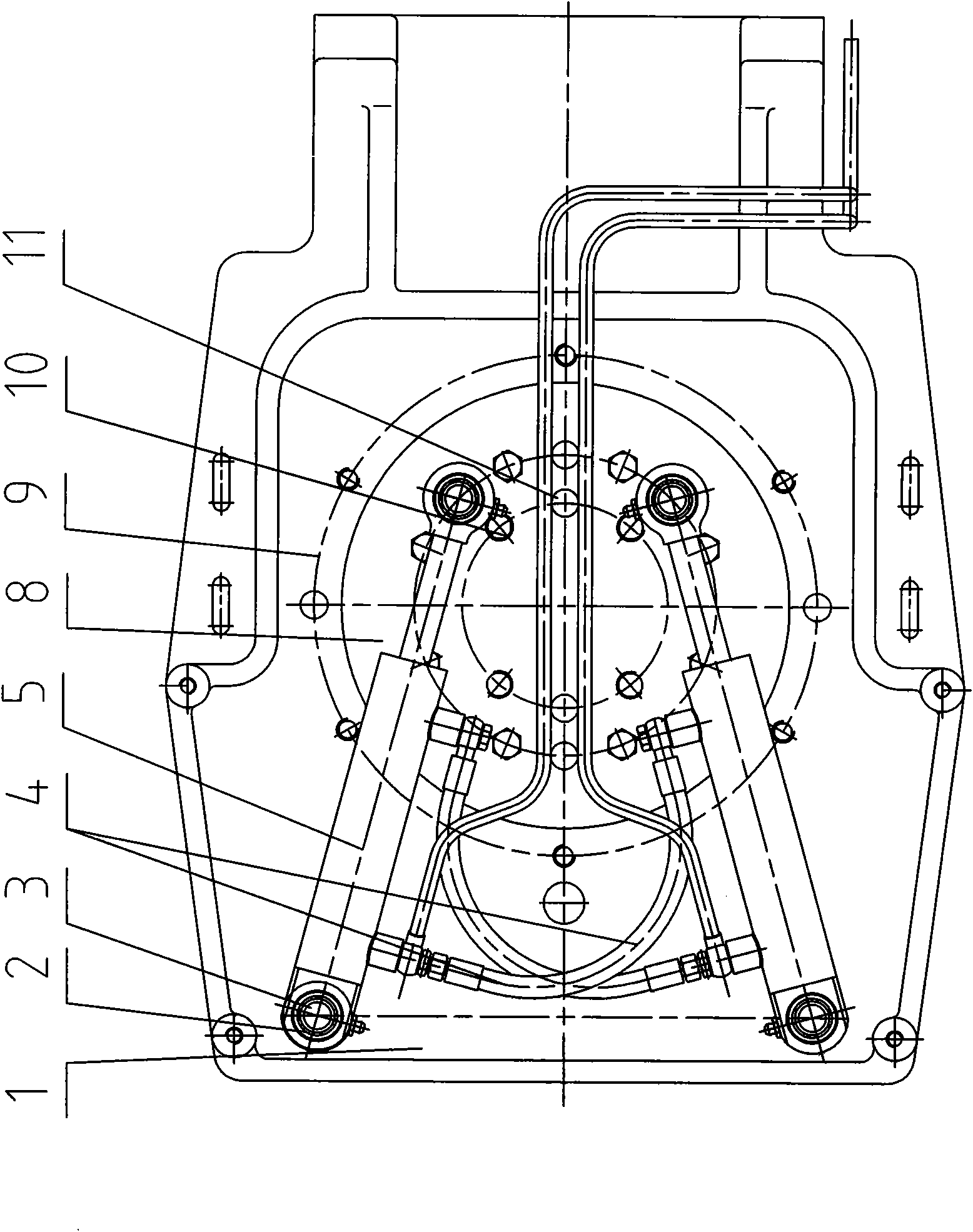

[0013] See figure 1 As shown, the three-wheel tractor steering mechanism of the present invention comprises steering wheel 19, frame 1, planar bearing, steering oil cylinder 5 and U-shaped fork 16, and planar bearing of the present invention comprises the bearing that two sides have upper raceway and lower raceway Seat 6, the driving disc 8 located on the upper part of the bearing housing 6 and the driven disc 9 and the ball 7 at the lower part, the lower part of the U-shaped fork 16 is connected with the steering wheel 19, and the upper part of the U-shaped fork 16 is connected with the driven disc with the outer raceway 9, the U-shaped fork 16 is fixedly connected to the driven disc 9 through the fastener 17 and the positioning pin 18. See figure 1 The shown frame 1 is connected to the flange of the bearing seat 6, and the bearing seat 6 is installed on the frame 1 by using fasteners 15 and positioning pins, and the bearing seat 6 is located between the upper raceway and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com