Heat pump type clothes dryer and working method thereof

A technology of a clothes dryer and a heat pump, which is applied in the field of clothes dryers, can solve the problems of high use cost, energy consumption, and large occupied volume, and achieve the effects of ensuring rapid dehumidification and drying, reducing volume, and saving output energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is attached Figure 1~4 The heat pump dryer and its working method proposed by the present invention will be further described in detail. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

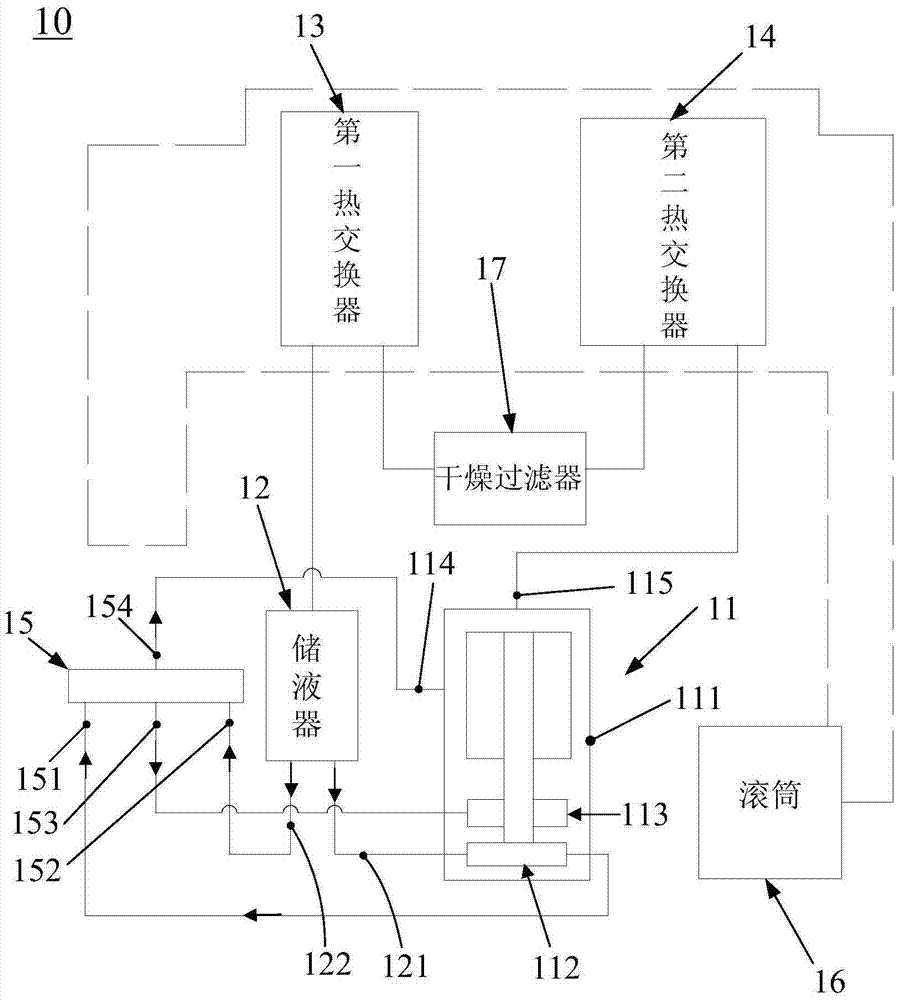

[0026] figure 1 A structural block diagram of a heat pump dryer provided by an embodiment of the present invention is shown. like figure 1 As shown, the heat pump dryer 10 includes a refrigerant circuit for refrigerant, and the refrigerant circuit includes a two-cylinder variable capacity compressor 11, a liquid receiver 12, a first heat exchanger 13, a second heat exchanger An exchanger 14 and a capacity switching device 15, the inlet of the accumulator 12 is connected to the first heat exchanger 13, and the second heat exchanger 14 is respectively connected to the first heat exchanger 13 and the doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com