Peeling machine of hibiscus cannabinus and jute

A peeling machine and technology of kenaf, applied in mechanical processing, fiber mechanical separation, textile and paper making, etc., can solve the problems of low efficiency of kenaf jute peeling, achieve strong skin and bone separation, high peeling rate, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

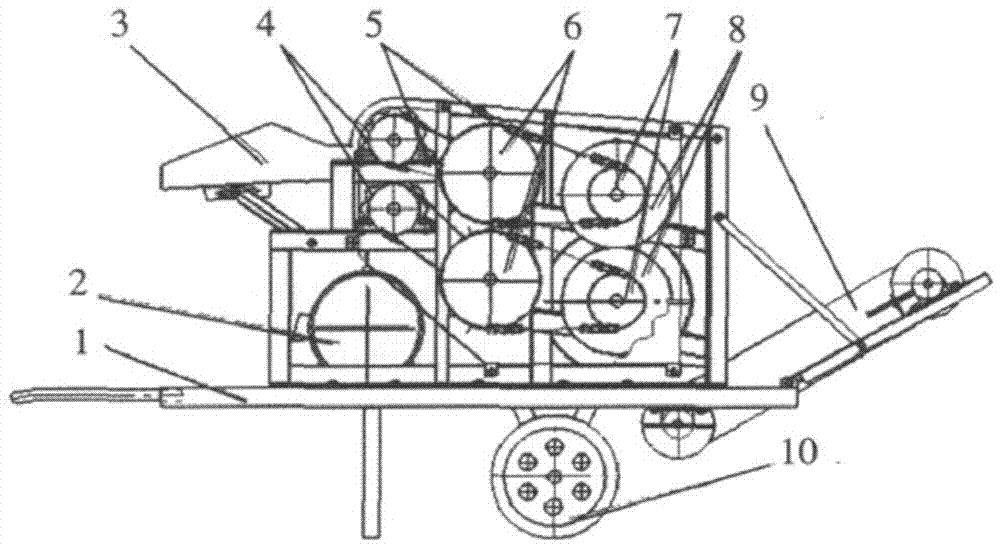

[0020] exist figure 1 Among them, including frame assembly, motor, feeding hopper, pressure roller group, chain, the first pair of peeling rollers, sprockets, the second pair of peeling rollers, hemp output device, walking wheels, kenaf jute warp feeding hopper (3 ) into the pressing roller group (4), and each hemp stalk is crushed by the pressing roller to realize the preliminary separation of the skin and bone of the stalk; the kenaf and jute after the preliminary separation enter the first pair of peeling rollers (6) and the second Knead the peeling cylinder (8) to completely separate the skin and bone of the yellow and kenaf stems. With the continuous operation of the machine, the separated fresh skin is output by the hemp output device (9).

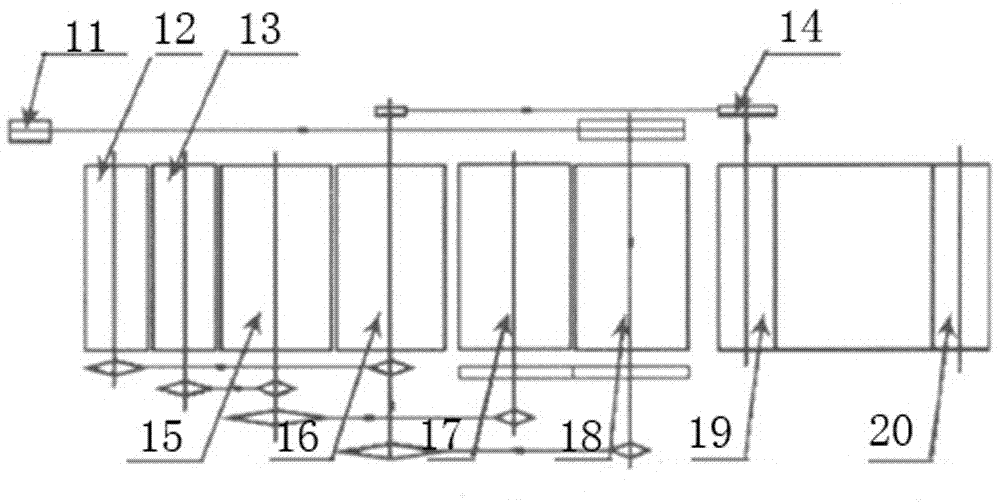

[0021] exist figure 2 Including motor pulley, lower pressure roller, upper pressure roller, conveyor belt pulley, peeling liquid cylinder 1, peeling liquid cylinder 2, peeling liquid cylinder 3, peeling liquid cylinder 4, conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com