Household sewage treatment process

A technology of domestic sewage and treatment process, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. , to achieve the effect of reducing high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

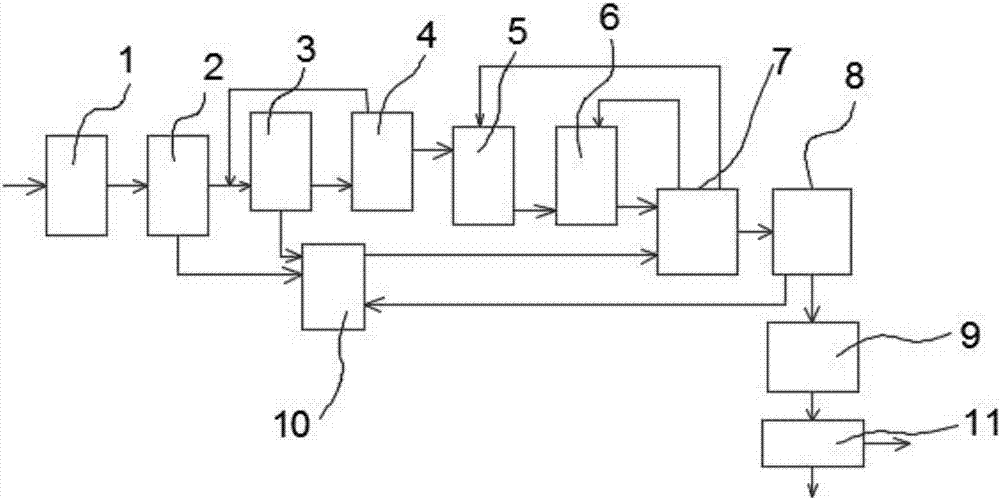

[0034] A domestic sewage treatment process carried out in cooperation with the above sewage treatment system, specifically comprising the following steps:

[0035] (1) Pretreat the sewage, specifically, enter the sewage into the grid well, use the grid in the grid well to filter and remove the large solid debris and part of the solid suspended matter in the sewage, and process it through the grit chamber to obtain Pretreatment of sewage;

[0036] (2) 85-90% of the pretreated sewage is subjected to anoxic treatment in the pre-anoxic tank, and the sludge age is 3-5 days;

[0037] (3) Enter the treated sewage into the flocculation tank for flocculation and sedimentation to obtain the upper layer liquid and the lower layer sludge;

[0038] (4) Perform anaerobic treatment and anoxic treatment on 80-90% of the supernatant and subsequent return sludge in sequence, and the sludge age is 5-10 days;

[0039] (5) Perform anaerobic treatment using the remaining pretreated sewage in step...

Embodiment 2

[0047] On the basis of Example 1, part of the lower layer sludge in step (3) was returned to the pre-anoxic tank for anoxic treatment.

[0048] During the flocculation and sedimentation in step (3), 200 g of flocculants are added to each cubic meter of sewage, and the flocculants include: 50 parts by weight of polyacrylamide, 16 parts of sodium carboxymethyl cellulose, nonylphenol polyoxyethylene ether 5 parts, calcium hydroxide 3 parts, polyferric chloride 7 parts, sodium alkylbenzene sulfonate 3 parts.

[0049] In step (9), a composite precipitant is used, and 50 g of a composite precipitant is added to each cubic meter of sewage. The composite precipitant includes: 10 parts of calcium polyacrylate, 6 parts of polyaluminum chloride, hydroxypropyl methylcellulose 5 parts, 5 parts of sodium pyrophosphate.

Embodiment 3

[0051] On the basis of Example 1 or 2, the mixed solution in step (6) is refluxed to step (4) for anoxic treatment, and the reflux ratio is 50-100%. The present embodiment is preferably 50%.

[0052] When flocculating and settling in step (3), 100 g of flocculant is added to each cubic meter of sewage, and the flocculant includes by weight: 50 parts of polyacrylamide, 18 parts of sodium carboxymethyl cellulose, nonylphenol polyoxyethylene ether 3 parts, 4 parts of calcium hydroxide, 8 parts of polyferric chloride, 1 part of sodium alkylbenzene sulfonate.

[0053] In step (9), a composite precipitant is used, and 80 g of a composite precipitant is added to each cubic meter of sewage. The composite precipitant includes, in parts by weight: 13 parts of calcium polyacrylate, 8 parts of polyaluminum chloride, 3 parts, 6 parts of sodium pyrophosphate.

[0054] Sewage treatment is carried out by adopting the processes of Examples 1-3, wherein the embodiment adopts the reflux of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com