Paper pressing device of paper cutting machine

A paper cutter and paper pressing technology, applied in the field of paper pressing devices, can solve problems such as obstruction of lifting, low pressure drop lifting efficiency, and pressing frame jamming, etc., to facilitate material reclaiming and installation, ensure dimensional accuracy, and improve assembly. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

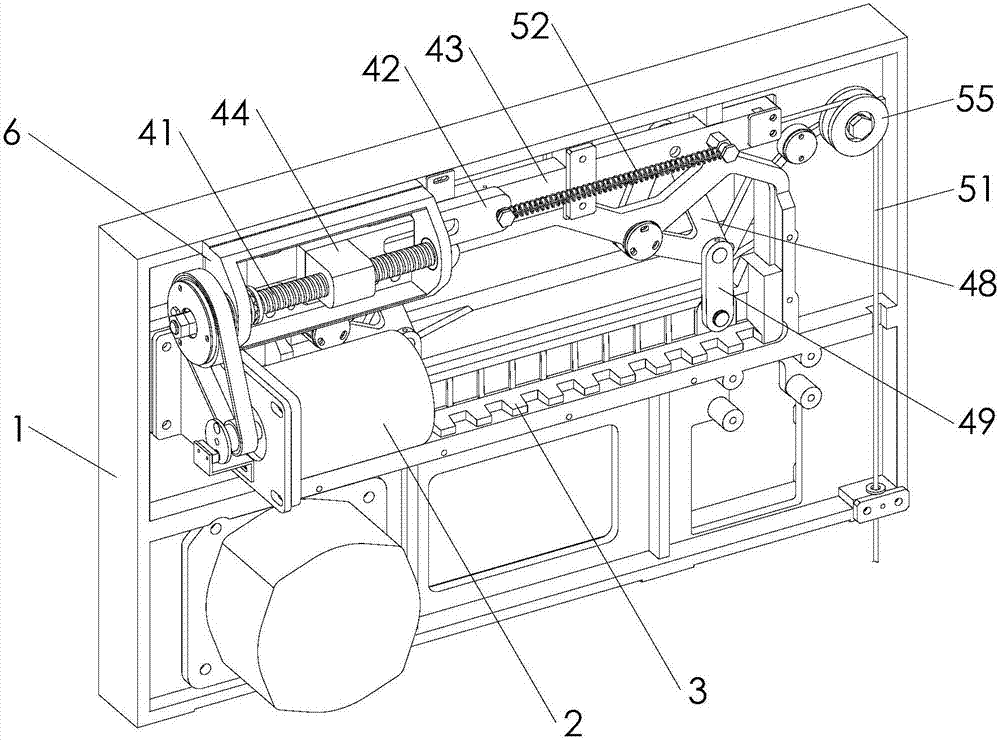

[0037] like figure 1 , figure 2 and image 3 As shown, the paper pressing device of the paper cutter provided by the first embodiment of the present invention includes a frame 1, a motor 2, a pressing plate 3, a transmission mechanism and a pre-pressing mechanism, and the motor drives the pressing plate to rise or fall through the transmission mechanism to realize pressing or The purpose of releasing the paper is realized by the pre-pressing mechanism.

[0038] In this embodiment, the motor 2 is fixed on the frame 1 through the fixing base 7 . The transmission mechanism includes a screw rod 41, a driving rod 42 and a sliding rod 43. The screw rod is controlled by the motor 2, the sliding rod is horizontally installed on the frame 1, the pressure plate 3 is connected to the sliding rod, and the driving rod is arranged on the screw rod and the sliding rod. The motor 2 drives the pressing plate to lower and compress the paper or rise to loosen the paper through the screw rod,...

Embodiment 2

[0057] The difference between the second embodiment of the present invention and the first embodiment is that the traction member adopts a traction chain, one end of the traction chain is fixedly connected to the front end of the sliding rod, and the other end of the traction chain is connected to the pedal.

[0058] Specifically in this embodiment, the traction chain can be an iron chain or a roller chain, and the iron chain is a chain in which a plurality of ring-shaped iron buckles are fastened in sequence. When the traction chain adopts the roller chain, the rollers use the gears that cooperate with the roller chain.

Embodiment 3

[0060] The difference between the third embodiment of the present invention and the first embodiment is that the foot pedal is replaced by a winch, the winch is provided with a handle that is deviated from the axis, and one end of the traction member is fixedly connected to the winch. When the winch is turned, the traction element is forced to move.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com