Efficient straightening and leveling assembly applied to silicon steel column

A silicon steel, leveling technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of affecting the correction effect, the deformation position of the silicon steel column is uncertain, and the correction failure, so as to achieve good correction and leveling effect and accurate improvement effect The effect of reducing the amount of correction errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

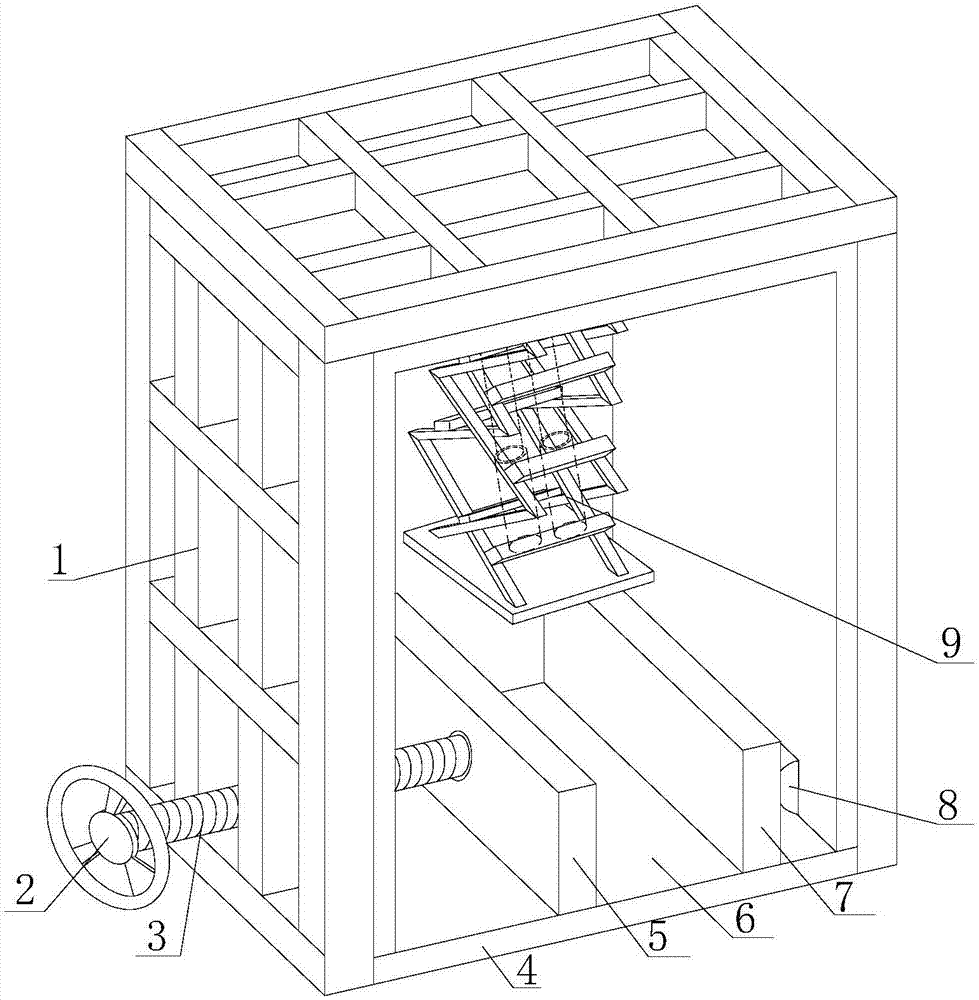

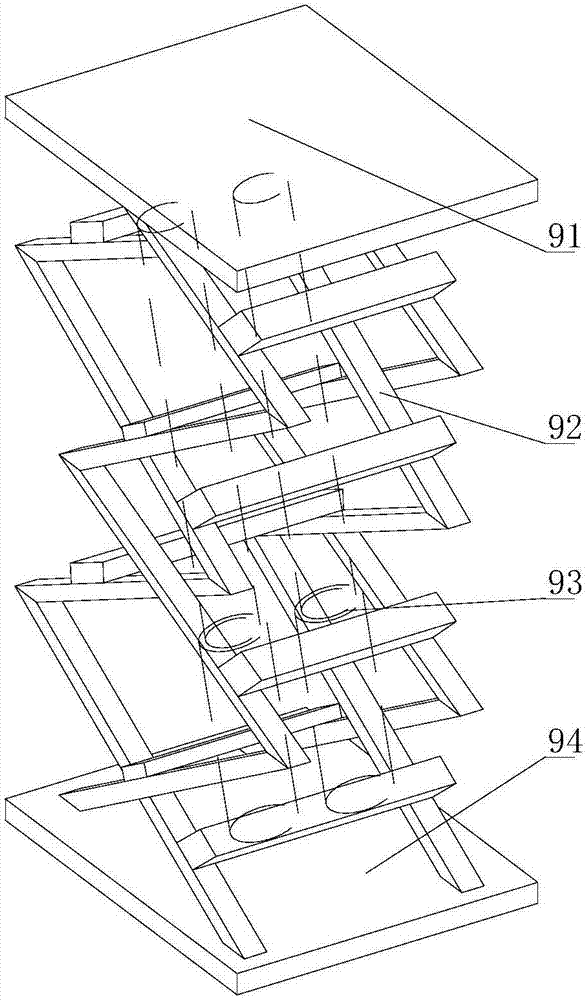

[0030]A high-efficiency correction and leveling component applied to a silicon steel column includes a square frame body 4 composed of four metal plates, and the front and rear sides of the square frame body 4 are open. A vertical correction device 9 and a horizontal correction device are arranged in the square frame body 4. The vertical correction device 9 can correct and level the silicon steel column from the vertical direction, and the horizontal correction device can correct and level the silicon steel column from the horizontal direction. flat. And when in use, the horizontal correction device and the vertical correction device 9 cooperate to correct and level the silicon steel column from both horizontal and vertical directions. The vertical correction device 9 includes a top connection plate 91, a bottom correction plate 94, and a telescopic frame 92 between the top connection plate 91 and the bottom correction plate 94. The two ends of the telescopic frame 92 are resp...

Embodiment 2

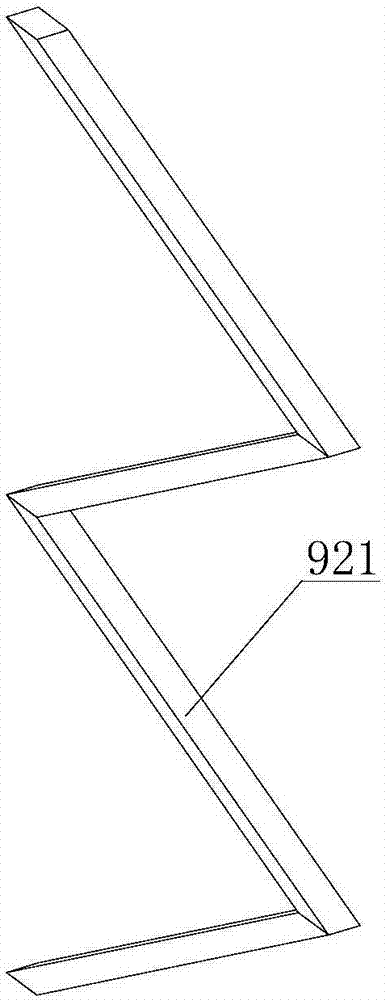

[0032] On the basis of Embodiment 1, the telescopic frame 92 includes at least four groups of telescopic frames, figure 2 Among them, the telescopic frame 92 comprises four groups of telescopic supports. Each set of telescopic brackets includes a plurality of support rods 921, the lower end of the upper support rod 921 is hinged with the upper end of the lower support rod 921, and the top of the uppermost support rod 921 is hinged with the top connecting plate 91. The bottom of the lower support rod 921 is hinged to the bottom correction plate 94 .

Embodiment 3

[0034] On the basis of Embodiment 1 or Embodiment 2, the level correction device includes a first splint 7 and a second splint 5 oppositely arranged on the inner bottom surface of the square frame 4, and the second splint 5 can slide horizontally relative to the first splint 7 , between the first splint 7 and the second splint 5, a silicon steel column correction and leveling channel 6 with adjustable spacing is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com