A fluid guider for externally thickened tubing

A technology of guides and thick oil pipes, applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as environmental pollution, time-consuming and labor-intensive, etc., to avoid environmental pollution, facilitate on-site access, and facilitate scale. The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

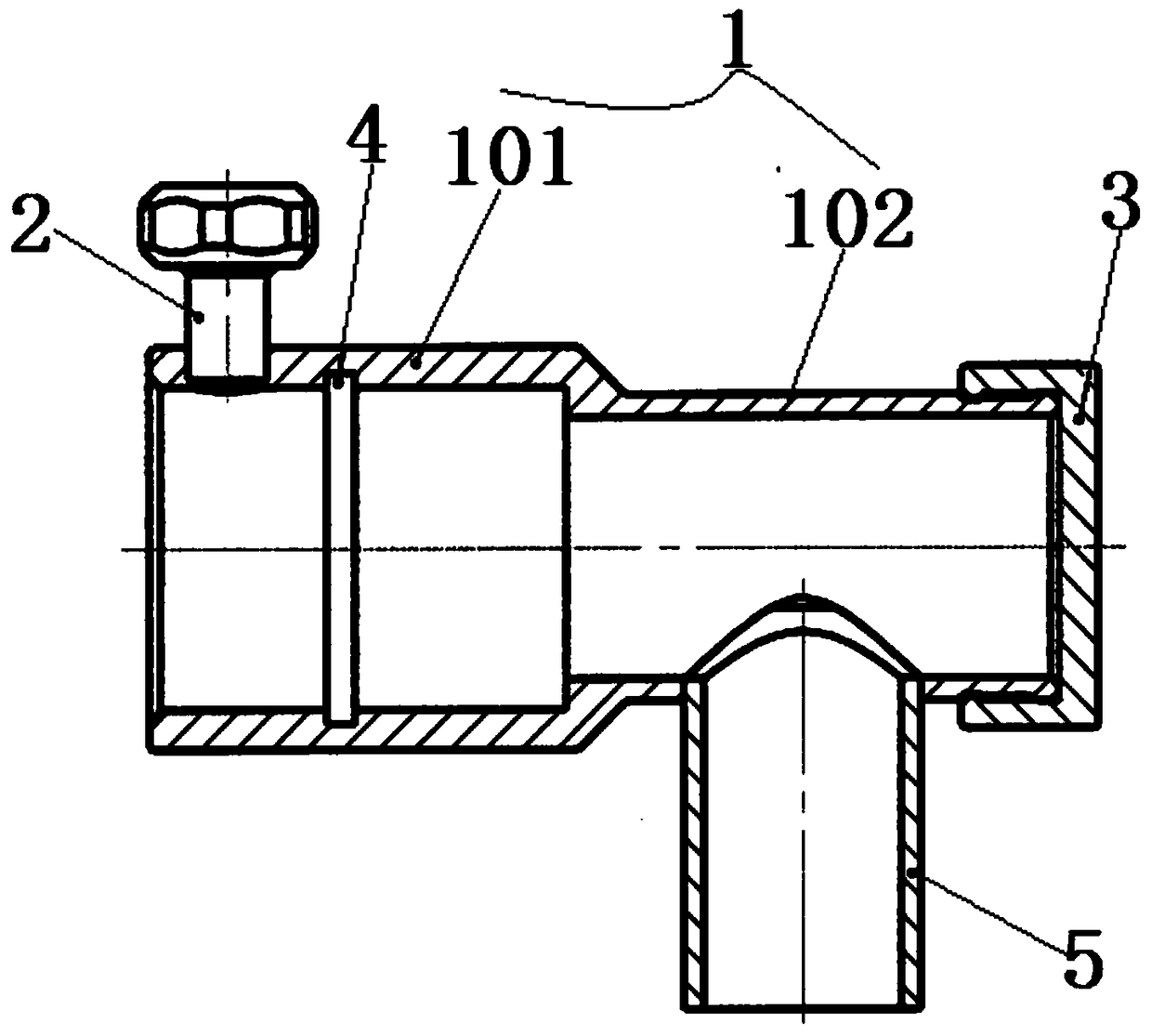

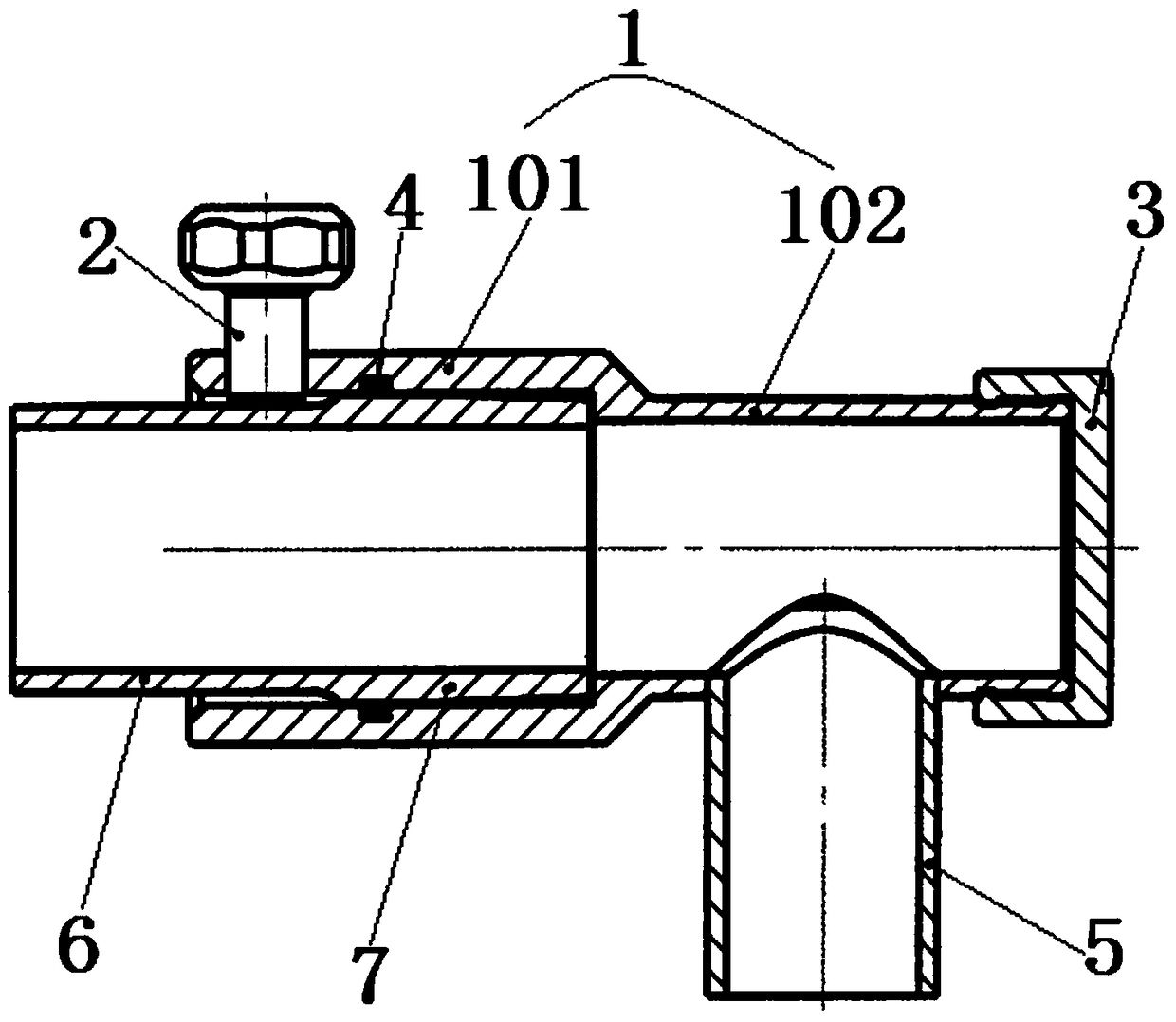

[0036] as attached figure 1 and attached figure 2 As shown, the embodiment of the present invention provides a fluid guide for externally thickened oil pipes, the fluid guide includes: variable diameter body 1, limit handle 2, plugging end cap 3, sealing ring 4 and drainage tube 5. Wherein, the variable diameter body 1 includes a large-diameter pipe section 101 and a small-diameter pipe section 102 connected in sequence, and a limiting step is provided at the connection between the large-diameter pipe section 101 and the small-diameter pipe section 102 . The inner diameter of the large-diameter pipe section 101 is 3-5 mm larger than the outer diameter of the upsetting section 7 of the outer thickened oil pipe, and the inner diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com