Fermented mango beverage and preparation method thereof

A technology for fermenting beverages and mangoes, applied in the directions of bacteria, food science, and applications used in food preparation, can solve problems such as affecting health, astringency in fruit juice beverages, and restricting the application of mangoes, achieving easy acceptance, unique taste, and full retention. The effect of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

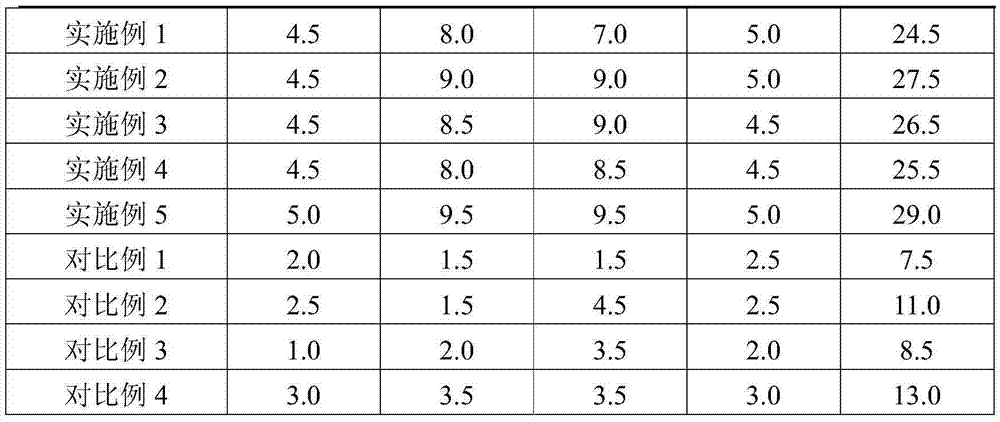

Examples

Embodiment 1

[0031] (1) Wash the mangoes, dry them, put them into boiling water, blanch them for 5 seconds, take them out and put them in cold water to cool immediately, and peel them;

[0032] (2) Add purified water to the peeled mango according to the ratio of material to liquid ratio 1:0.5, stir evenly, beat for 20 minutes, homogenize 3 times, the first homogenization pressure is 20-25Mpa, and the second homogenization pressure is 20 -25Mpa, the third homogeneous pressure is 35-40Mpa;

[0033] (3) Place the homogenized feed liquid in a fermenter, add glucose and sucrose respectively according to 8% of the feed liquid volume, mix evenly, and sterilize;

[0034] (4) Mix Lactobacillus plantarum, Lactobacillus acidophilus, Lactobacillus casei, and Lactobacillus paracasei in a ratio of 8:2:10:1, and add 1% of the volume of the feed liquid into the sterilized feed liquid, Stir well, ferment at 34-38°C for 47 hours, until pH=3..8 is the end point of fermentation, and obtain mango puree;

[0...

Embodiment 2

[0037] (1) Wash the mangoes, dry them, put them into boiling water, blanch them for 5 seconds, take them out and put them in cold water to cool immediately, and peel them;

[0038] (2) Add purified water to the peeled mango according to the ratio of material to liquid ratio 1:0.8, stir evenly, beat for 10 minutes, homogenize twice, the first homogenization pressure is 20-25Mpa, the second homogenization pressure is 35 -40Mpa;

[0039] (3) Place the homogenized feed liquid in a fermenter, add glucose and sucrose respectively according to 12% of the feed liquid volume, mix evenly, and sterilize;

[0040] (4) The four strains of Lactobacillus plantarum, Lactobacillus acidophilus, Lactobacillus casei, and Lactobacillus paracasei are used after domestication and screening by the following steps:

[0041] a. High glucose resistance: add glucose to the MRS medium, the proportion of glucose used is 40%, 50%, 60%, after inoculating the above four strains respectively, culture at 37±1°...

Embodiment 3

[0046] (1) Wash and dry the mangoes, put them into boiling water, blanch for 10 seconds, take them out and put them in cold water to cool immediately, and peel them;

[0047] (2) Add purified water to the peeled mango according to the ratio of material to liquid 1:1, stir evenly, beat for 30 minutes, homogenize twice, the first homogenization pressure is 20-25Mpa, and the second homogenization pressure is 35Mpa -40Mpa;

[0048] (3) Place the homogenized feed liquid in a fermenter, add glucose and sucrose respectively according to 11% of the feed liquid volume, mix evenly, and sterilize;

[0049] (4) The four strains of Lactobacillus plantarum, Lactobacillus acidophilus, Lactobacillus casei, and Lactobacillus paracasei are used after domestication and screening by the following steps:

[0050] a. High glucose resistance: add glucose to the MRS medium, the proportion of glucose used is 40%, 50%, 60%, after inoculating the above four strains respectively, culture at 37±1°C for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com