Photovoltaic DC power supply system and method for electrolytic aluminum electrolytic production

A power supply system, electrolytic aluminum technology, applied in photovoltaic power generation, battery circuit devices, current collectors, etc., can solve the problems of power grid peak-valley adjustment influence, single mode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

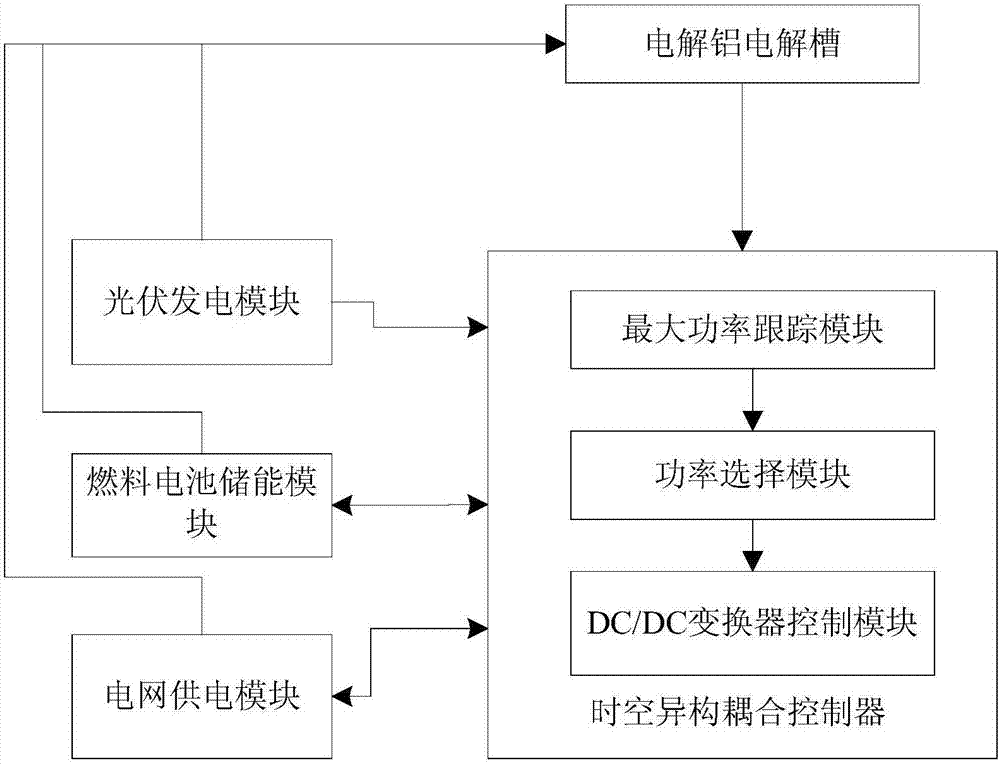

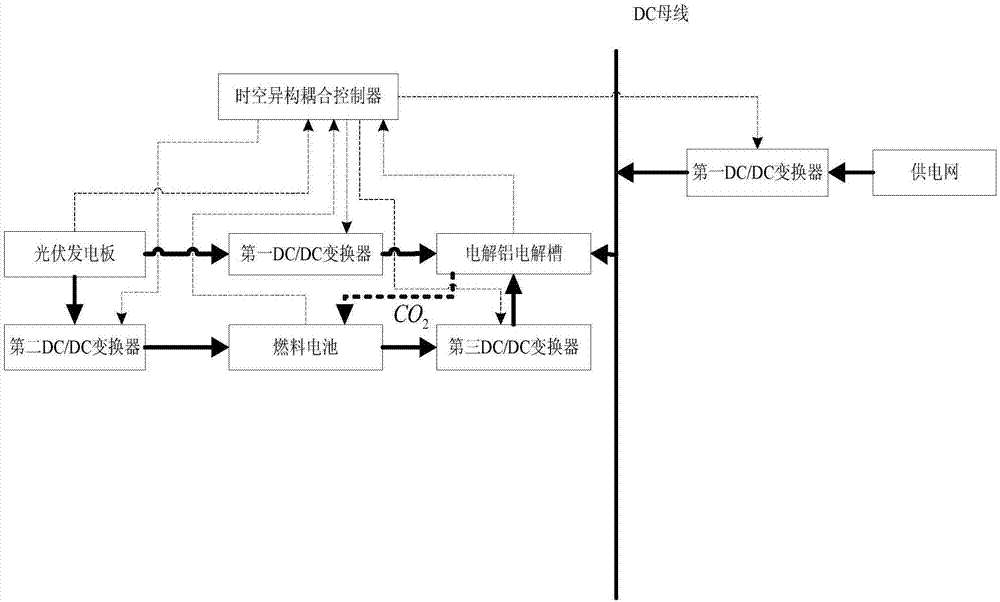

[0054] A photovoltaic DC power supply system for the electrolytic production of electrolytic aluminum, such as figure 1 As shown, it includes photovoltaic power generation module, fuel cell energy storage module, space-time heterogeneous coupling controller and grid power supply module.

[0055] The photovoltaic power generation module is used to provide DC power for the electrolytic aluminum electrolytic cell and charge the fuel cell energy storage module.

[0056] The fuel cell energy storage module is used to store the remaining electric energy of the photovoltaic power generation module through power-to-gas when the maximum output power of the photovoltaic power generation module is greater than the power required by the electrolytic aluminum electrolytic cell, and the fuel cell storage is required in the electrolytic aluminum electrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com