Air floatation machine automatic residue removing mechanism

A technology of automatic slag removal and air flotation machine, applied in the field of air flotation machine, can solve the problems of complex structure and insufficient energy saving of slag scraper, and achieve the effect of low cost and no operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

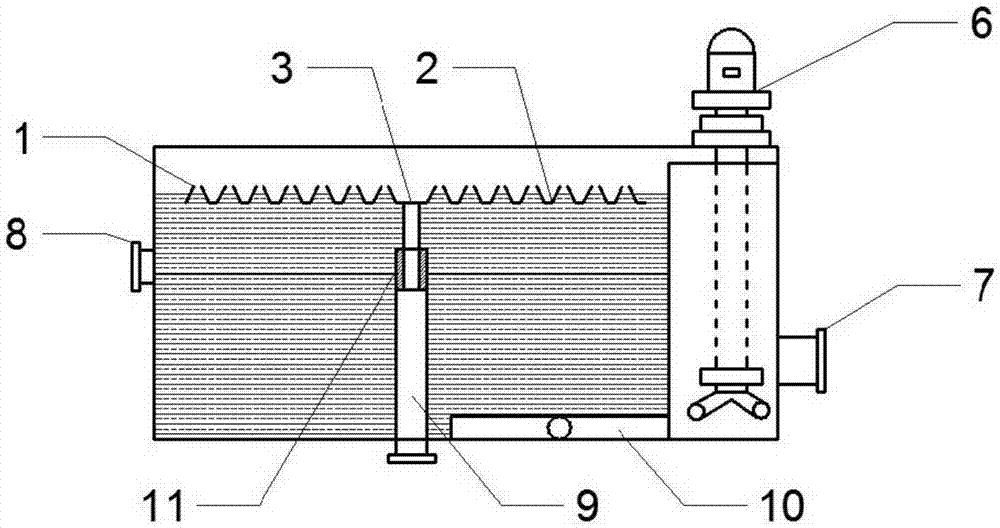

[0021] like figure 2 The vortex-concave air flotation machine shown includes an automatic slag removal mechanism, an aerator 6, a water inlet 7, a water outlet 8, a sewage casing 9, a return pipe 10, and a sealing ring 11. The sewage enters the air through the water inlet 7. Floater, mixed with small air bubbles under the action of the aerator 6, the suspended matter in the sewage rises to the automatic slag removal mechanism under the buoyancy of the small bubbles to be removed, and the treated sewage is discharged from the outlet 8.

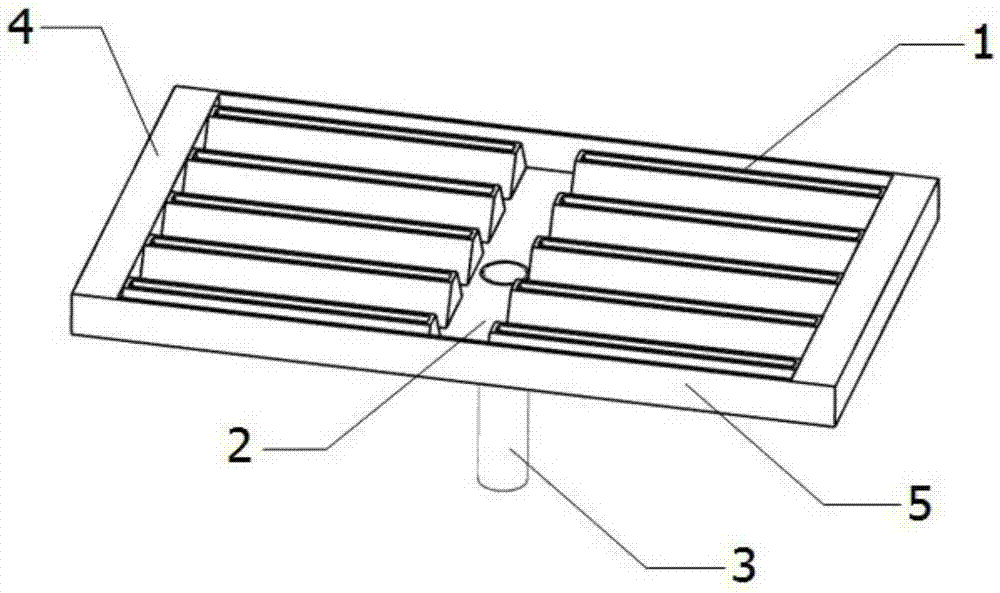

[0022] like figure 1 As shown, an automatic slag removal mechanism for an air flotation machine includes an overflow port 1, a groove channel 2, a sewage pipe 3, a float 4, and a water retaining side wall 5. The overflow port is trapezoidal in cross section, small at the top and large at the bottom , there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com