Backlight module and liquid-crystal display device

A backlight module and backplane technology, applied in optics, nonlinear optics, television, etc., can solve problems such as crowded lights, complicated design and printing process, color cast, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

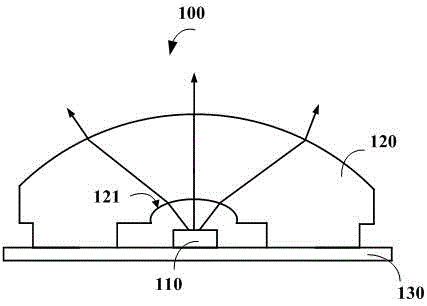

[0034] In the existing direct type backlight module, the structure of the optical device is as follows figure 1 As shown, the optical device 100 includes an LED light source 110 , an optical lens 120 and a PCB board 130 , wherein the LED light source 110 is disposed on the PCB board for providing a backlight source, and the optical lens 120 is fixedly connected to the PCB board 130 . Wherein, the optical lens 120 is used to diffuse the light path emitted by the LED light source, so that the backlight provided by the LED light source is emitted at a larger angle, and the emission range of the light path of the backlight is increased, so that it can emit from the display area more uniformly.

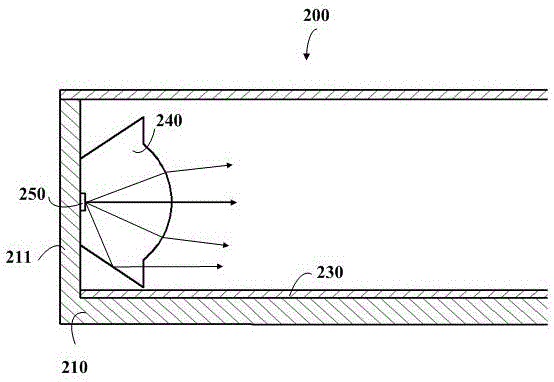

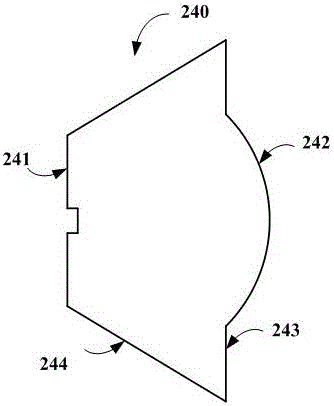

[0035] Obviously, if the optical devices of the existing direct-type backlight module are directly used in the side-type backlight module without a light guide plate, most of the light path will still exit from the near-beam side of the light source, and the side point / Line lights are con...

Embodiment 2

[0064] Embodiment 2 of the present application further provides a liquid crystal display device, comprising a liquid crystal panel and the backlight module described in Embodiment 1 above. Wherein, the backlight module and the liquid crystal panel are at opposite positions, and the liquid crystal panel is located on the upper surface of the backlight module; the structure, function and function of the backlight module have been described in detail in the foregoing embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com