Connector and locking sleeve thereof

A technology of connectors and locking sleeves, which is applied in the direction of connection, parts of connection devices, electrical components, etc., can solve the problem of forced separation of connectors, etc., and achieve simple and convenient design, strong versatility, and increased radial distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

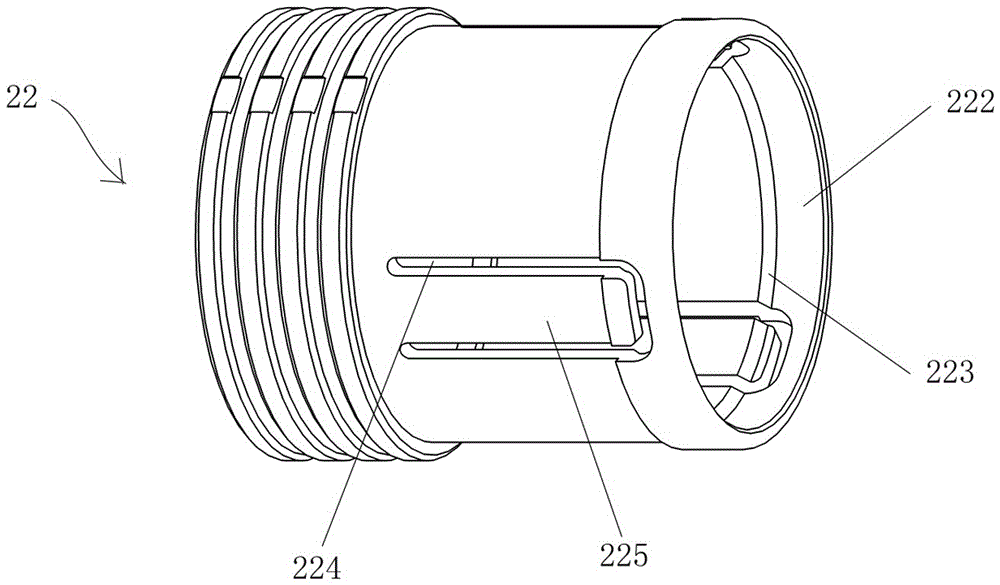

[0023] The specific structure of the push-pull connector assembly is as follows: Figure 2 to Figure 4 As shown, a plug connector 1 and a socket connector 2 are included, and the socket connector 2 constitutes a specific embodiment of the connector of the present invention.

[0024] The socket connector 2 includes an inner housing 21 and a locking sleeve 22 fitted outside the inner housing 21 . The gap between the inner housing 21 and the locking sleeve 22 constitutes an insertion space for the plug connector 1 to be inserted into. The outer periphery of the inner casing 21 is provided with a first annular boss 211, and the locking sleeve 22 includes a sleeve body. A second annular boss 221 is arranged on the inner peripheral surface of the sleeve body. The side wall surface and the left side wall surface of the first annular boss 211 block and coopera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com