Flexible touch display screen and manufacturing method thereof

A technology of flexible touch and manufacturing methods, applied in the direction of nonlinear optics, static indicators, optics, etc., can solve the problem of increasing the overall thickness of the touch display screen, and achieve the effect of reducing the overall thickness and reducing the bonding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Wherein, the accompanying drawings are only used for exemplary illustration, and represent only schematic diagrams, and should not be understood as limitations on this patent.

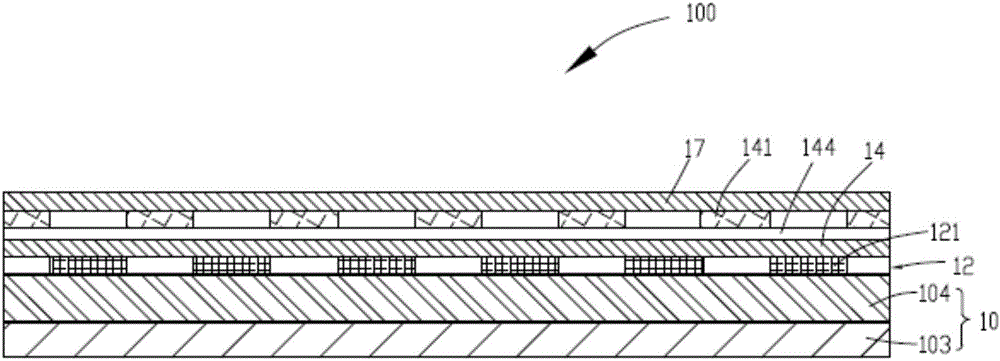

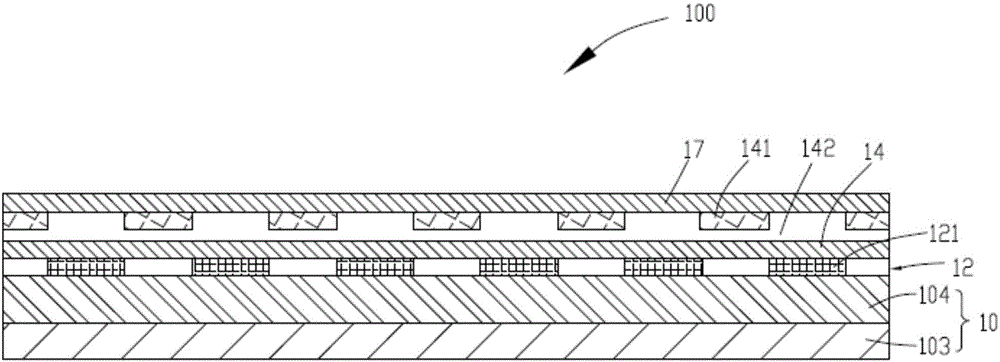

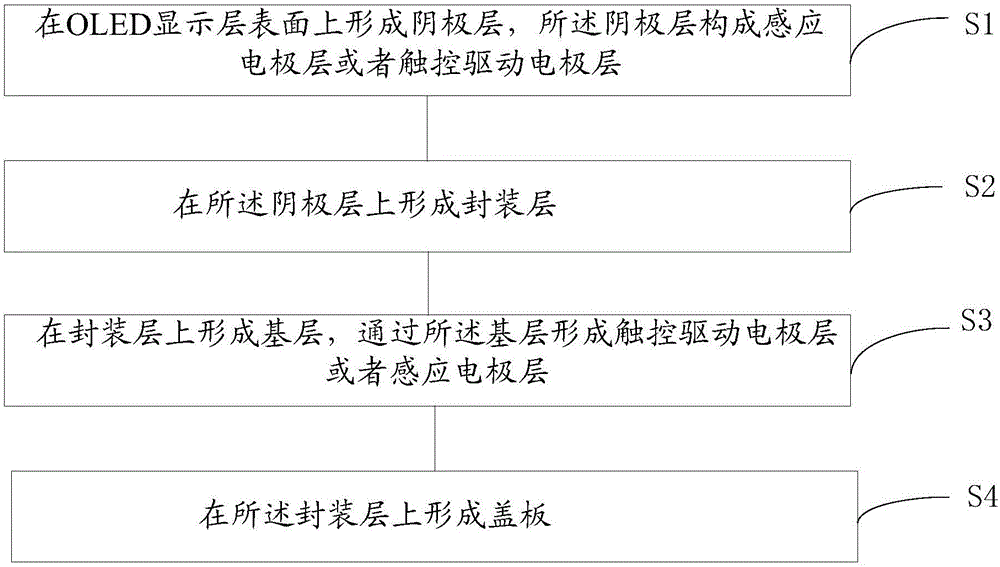

[0027] see figure 1 , the embodiment of the present invention provides a flexible touch display screen 100, which includes an OLED display layer 10 and a drive module 20, a cathode layer 12 and an encapsulation layer covering the cathode layer 12 are sequentially stacked on the surface of the OLED display layer 10 14. The cathode layer 12 is connected with the driving module. The cathode layer 12 constitutes a sensing electrode layer or a touch driving electrode layer, corresponding to the sensing electrode layer or touch driving electrode layer of the cathode layer 12, and the packaging layer 14 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com