Test method for safety grade evaluation of lithium ion battery

A lithium-ion battery, safety-level technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as thermal runaway, sample swelling, self-heating, etc., achieve effective control, reasonable test content, and reduce detection workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] For new products whose safety performance is unknown, the safety level is determined by the following tests:

[0043] Short circuit test:

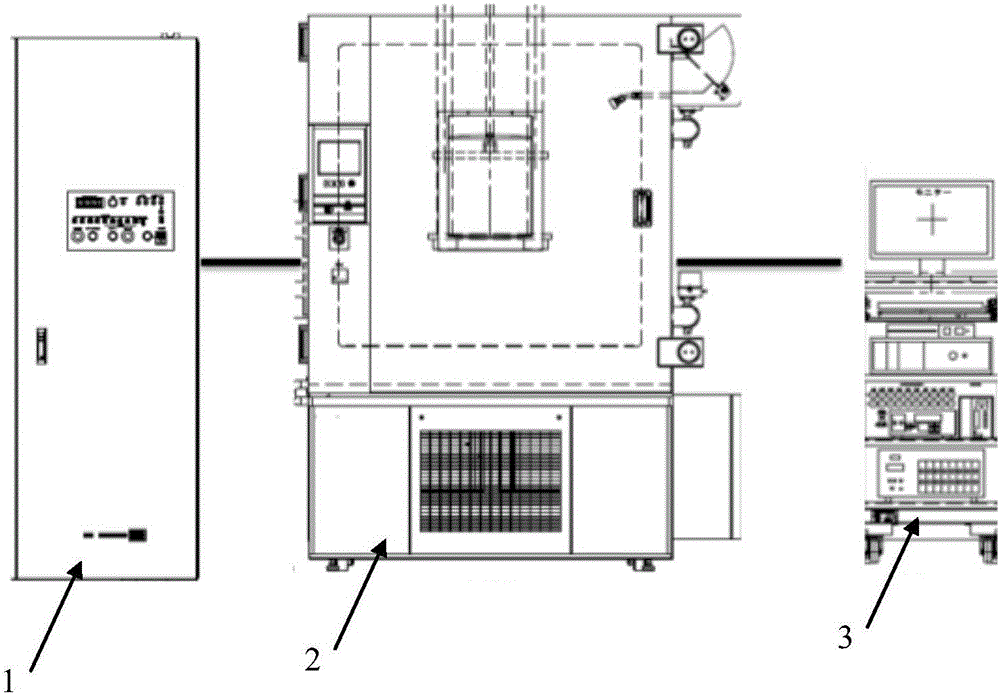

[0044] 1) At 25°C, put a single battery in the environmental chamber and let it stand for 30 minutes to ensure that the overall temperature of the single battery is consistent with the temperature in the environmental chamber;

[0045] 2) Perform short-circuit excitation to the single battery in step 1), the short-circuit resistance is 10min;

[0046] 3) Record the voltage, short-circuit current and temperature changes of the short-circuit battery, and test the state and weight of the single battery before and after the experiment.

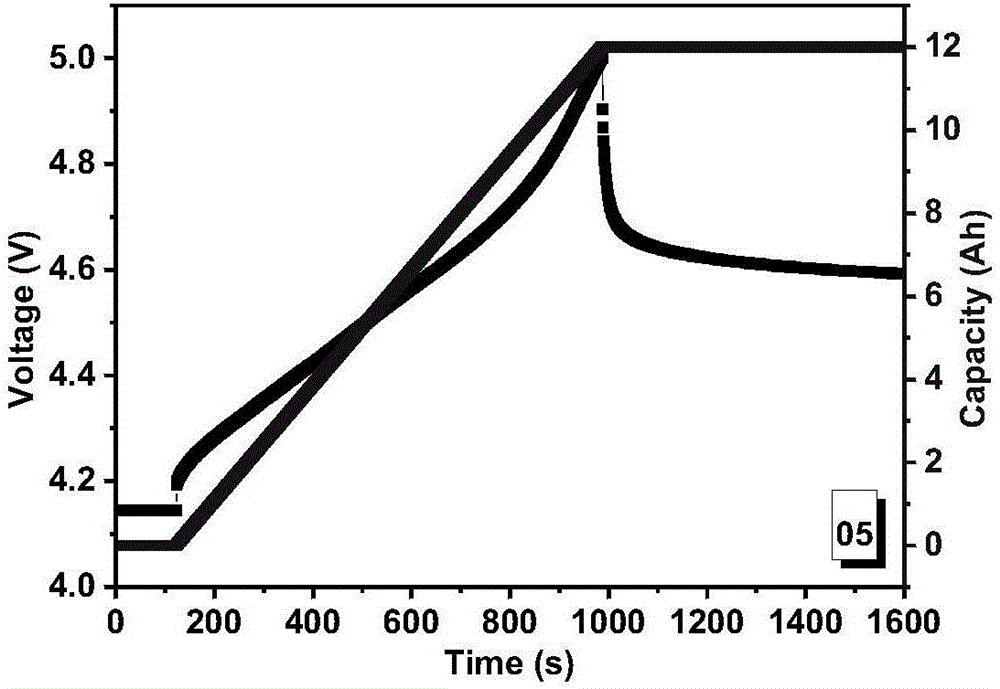

[0047] Overcharge test:

[0048] 1) At 25°C, put a single battery in the environmental chamber and let it stand for 30 minutes to ensure that the overall temperature of the single battery is consistent with the temperature in the environmental chamber;

[0049] 2) Excite the single battery in step 1)...

Embodiment 2

[0066] For products using safety technology, the safety level is determined by the following tests:

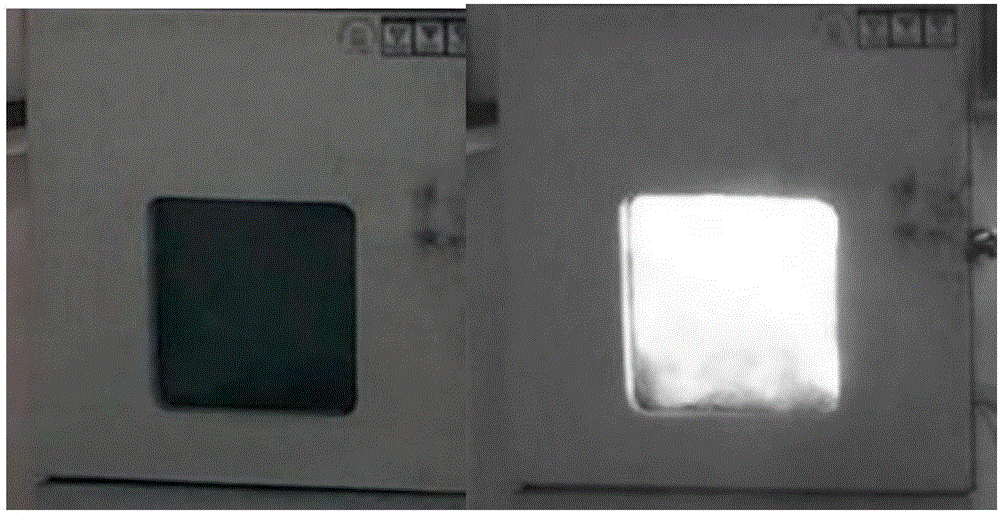

[0067] Heating test:

[0068] 1) At 25°C, put a single battery in the environmental chamber and let it stand for 30 minutes to ensure that the overall temperature of the single battery is consistent with the temperature in the environmental chamber;

[0069] 2) Heating the single battery in step 1), the heating temperature is 150°C, and the heating time is 60 minutes;

[0070] 3) Record the voltage and temperature changes of the heating battery, and test the state and weight of the single battery before and after the experiment.

[0071] Short circuit test:

[0072] 1) At 25°C, put a single battery in the environmental chamber and let it stand for 30 minutes to ensure that the overall temperature of the single battery is consistent with the temperature in the environmental chamber;

[0073] 2) Perform short-circuit excitation on the single battery in step 1), the short-circ...

Embodiment 3

[0086] For products that have passed the low and medium safety tests, the following tests are used to determine whether they meet the high safety level. The test samples are from the same batch of products.

[0087] 1) At 45°C, put a single battery in the environmental chamber and let it stand for 60 minutes to ensure that the overall temperature of the single battery is consistent with the temperature in the environmental chamber;

[0088] 2) Short-circuit the single battery in step 1), the short-circuit resistance is 10min;

[0089] 3) Record the voltage, short-circuit current and temperature changes of the short-circuit battery, and test the state and weight of the single battery before and after the experiment.

[0090] 65°C short circuit test:

[0091] 1) At 65°C, put the single battery that has passed step 3) into the environmental chamber, and let it stand for 60 minutes to ensure that the overall temperature of the single battery is consistent with the temperature in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com