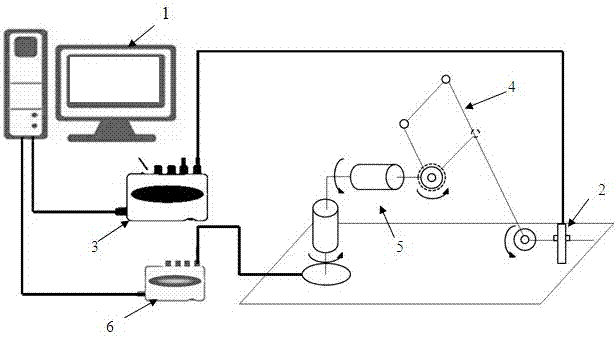

Positioning ultrasonic testing device and method for curved surface welded parts

A technology for ultrasonic testing and welding parts, which is applied in measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., and can solve problems such as difficult quantitative ultrasonic testing of complex curved surface parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

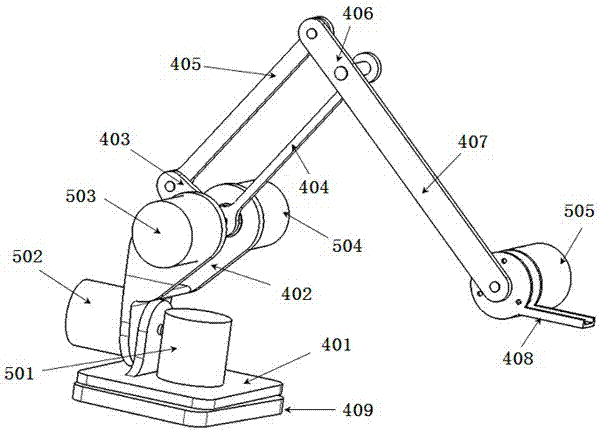

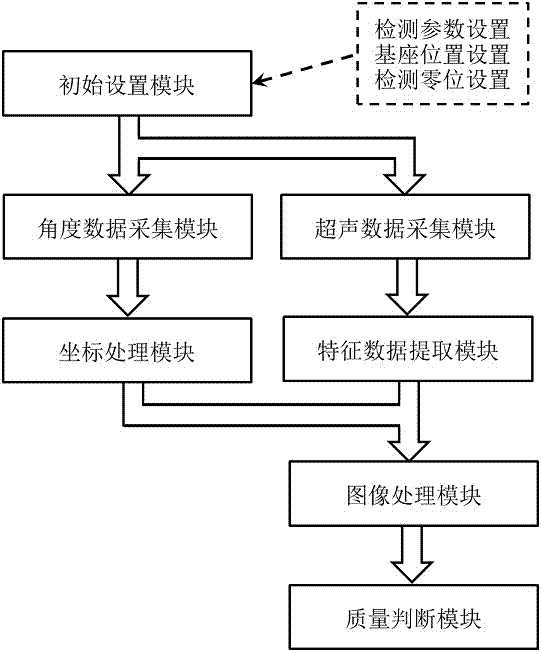

[0078] A method for positioning and ultrasonic detection of curved welded parts based on a series-parallel hybrid mechanism. The specific implementation steps are as follows:

[0079] 1. Surface treatment of the workpiece: Before scanning the data, the surface of the vibration friction welding workpiece in the airbag area of the car dashboard is treated with dust, oil, and coupling agent to reduce the interference of the surface impurities on the ultrasonic signal.

[0080] 2. Enter the surface shape data of the scanned workpiece and plan the placement of the multi-link robotic arm base. Import the three-dimensional surface STP format data of the vibration friction welding workpiece in the airbag area of the car dashboard into the system through the USB interface, and plan the placement of the multi-link manipulator base through the spatial position that the ultrasonic probe can reach. The spatial dimension of the workpiece is 44.3mm*40.7mm*11.6mm, among which the welding area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com