Double-vibration-table connection structure

A technology of connecting structure and double shaking table, which is applied in vibration testing, testing of machine/structural components, measuring devices, etc., can solve the problems of the connecting structure consumes thrust, insufficient thrust, and the test piece fails to meet the assessment, and achieves extended loading. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

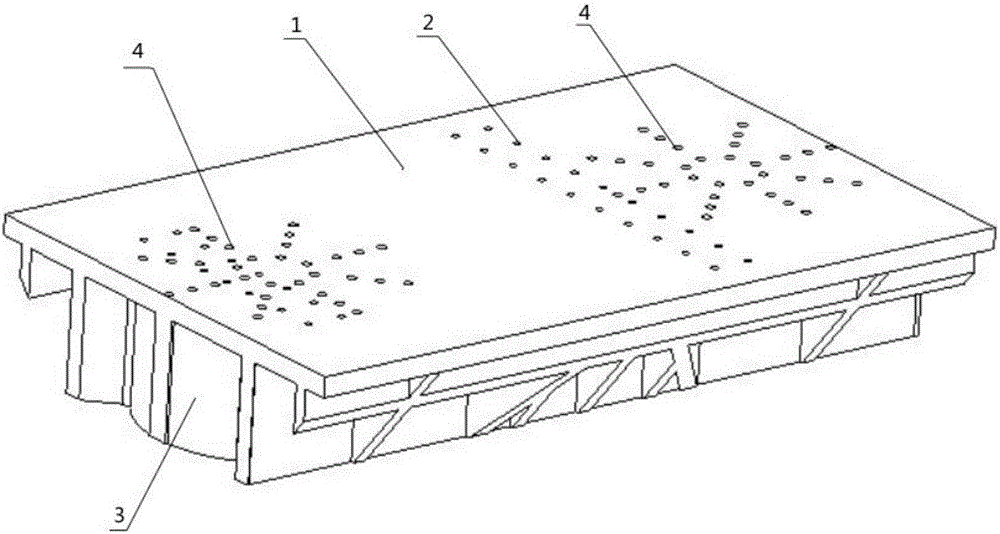

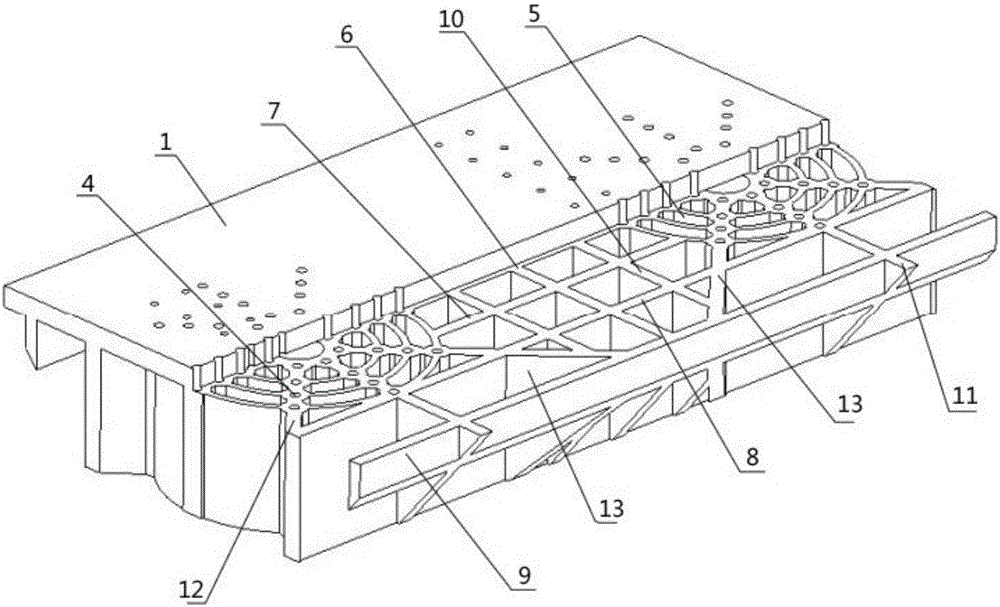

[0014] Such as figure 1 with figure 2 As shown, a double vibrating table connection structure of the present invention includes a connection panel 1, a connection base 3 and a force transmission structure. The connection panel 1 is provided with bolt holes 2 for connecting with test specimens, and the upper ends of the two connection bases 3 Both are fixedly connected with the lower side of the connection panel 1, and the connection base 3 is provided with a connection hole 4 for connecting with the vibrating table. The lower side of 1 is fixedly connected, the connecting base 3 is a circular structure, and the inside of the connecting base 3 is provided with a plurality of weight-reducing holes 5, the connecting holes 4 are arranged on the connecting plate arranged along the radial direction of the connecting base 3, and the connecting panel 1 is provided with a through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com