Novel bevel gear vehicle brake clearance automatic adjusting arm

A technology for automatic adjustment of arms and automobile braking, applied in the direction of slack adjusters, etc., can solve the problems of inconvenient and reliable installation and use, inflexible adjustment of adjustment arms, affecting the accuracy of adjustment arms, etc., so as to shorten the braking response, adapt to Wide range of models, eliminating the effect of braking lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

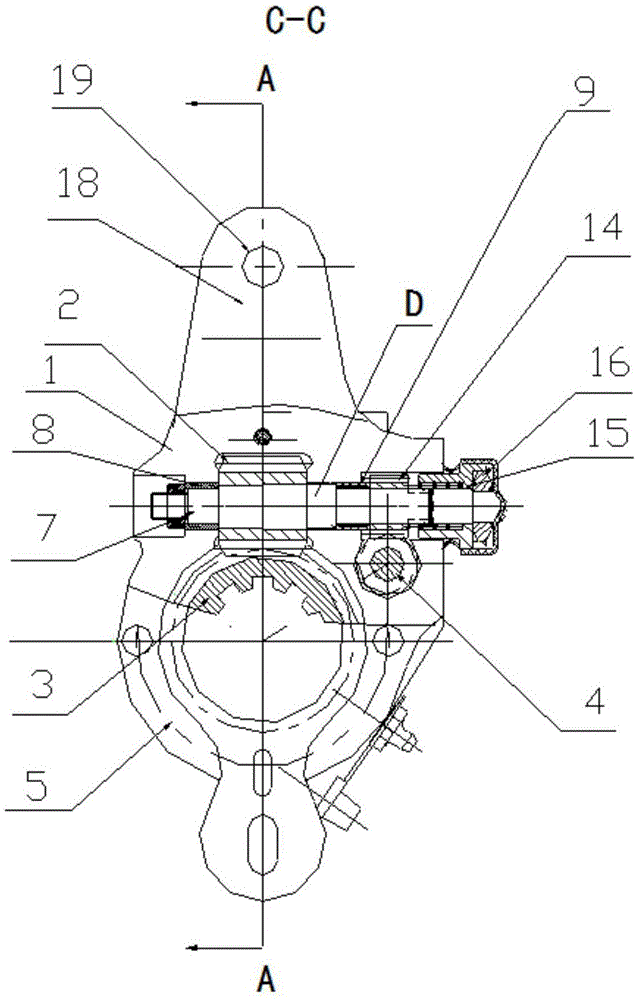

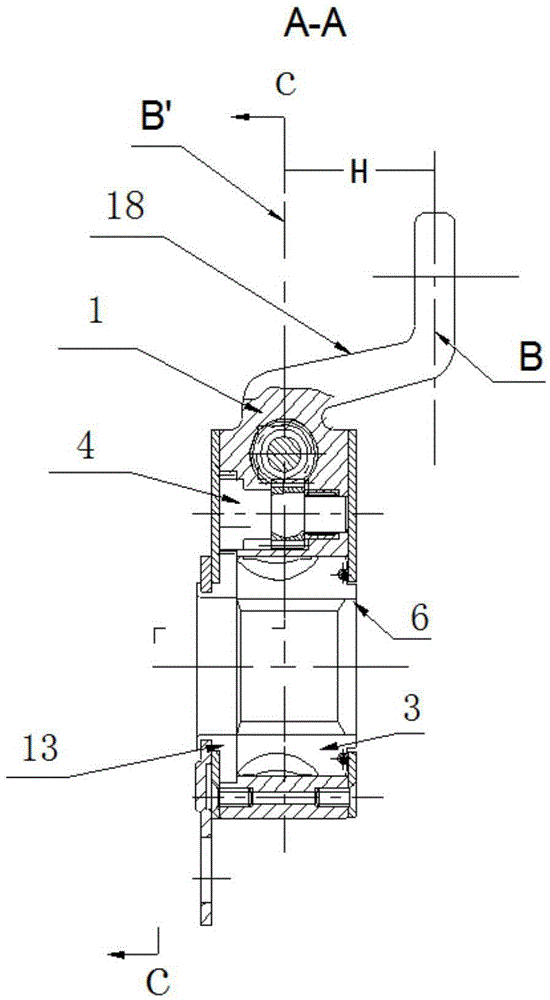

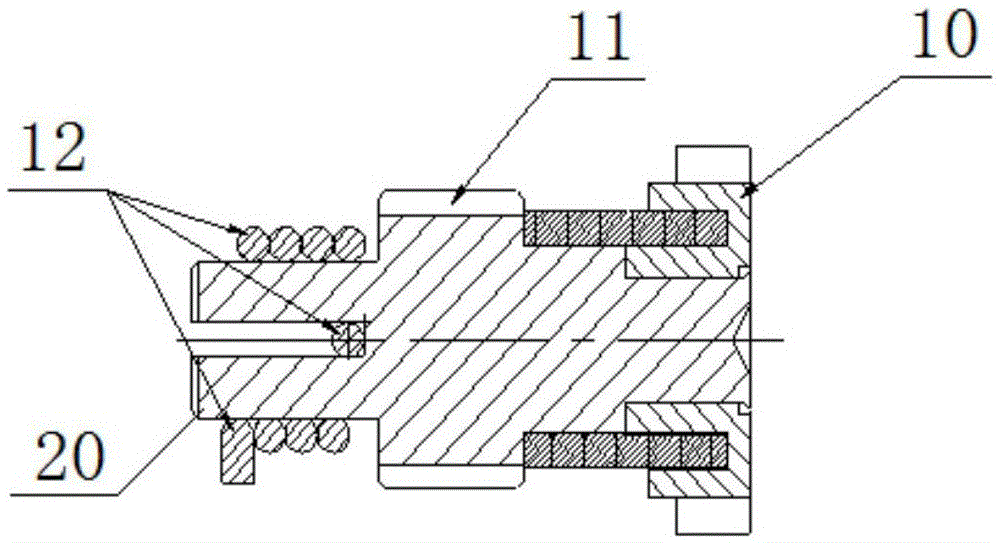

[0025] attached by figure 1 , 2 , 4, and 5: the adjusting arm includes a housing (1) with an arm handle (18), a worm (2) set in the housing (1) and fitted on the main part D of the worm shaft, and the worm ( 2) Mesh the worm gear (3), the clutch assembly (4) and the rear cover plate (6) with the spline shaft hole in the center, and it is characterized in that it also includes a front cover plate assembly (5). The front cover assembly (5) is provided with a driving gear (13) and a ferrule (17) to overcome the free stroke of the brake assembly deformation, and the clutch assembly (4) is provided with a return spring (12) , the clutch assembly (4) adopts a torsion spring structure to realize unitless adjustment; the active helical gear (11) on the clutch assembly (4) and the passive helical gear (14) on the worm shaft (7) The angle range of the helical gear used for meshing and engagement is 35-45 degrees, which is suitable for various brake chamber power requirements; the arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com