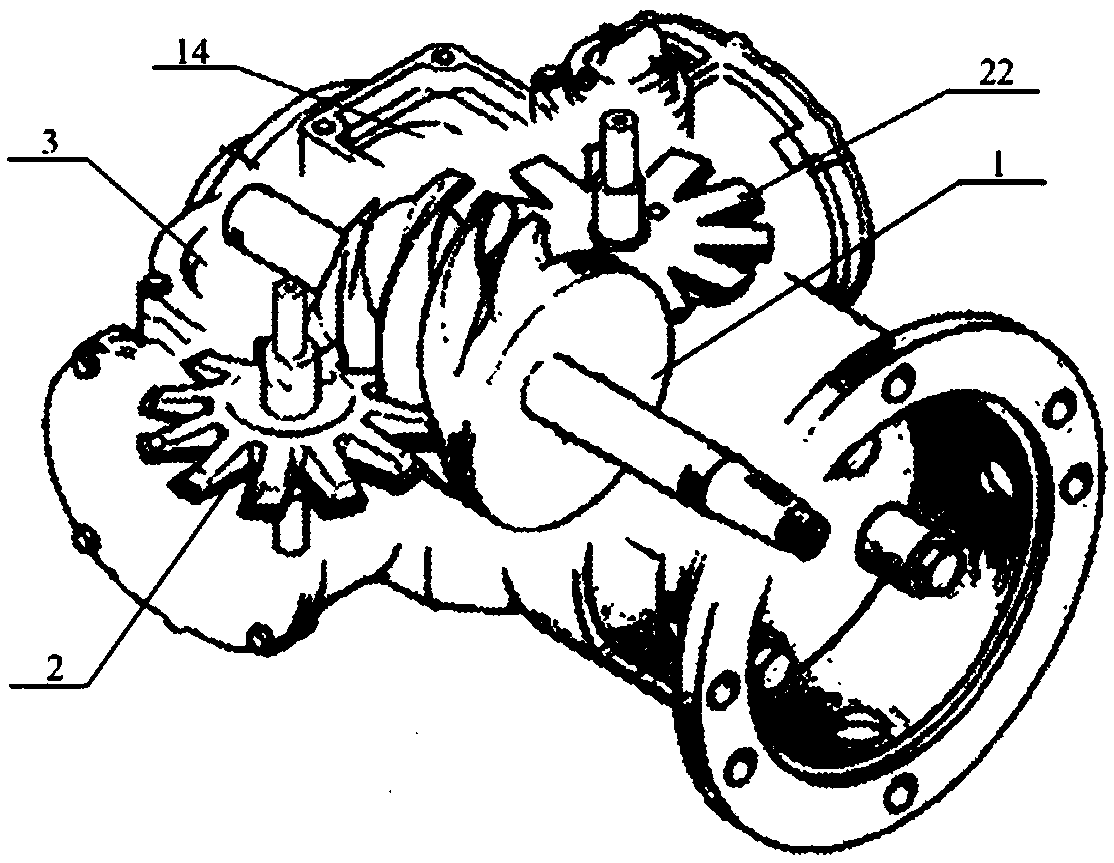

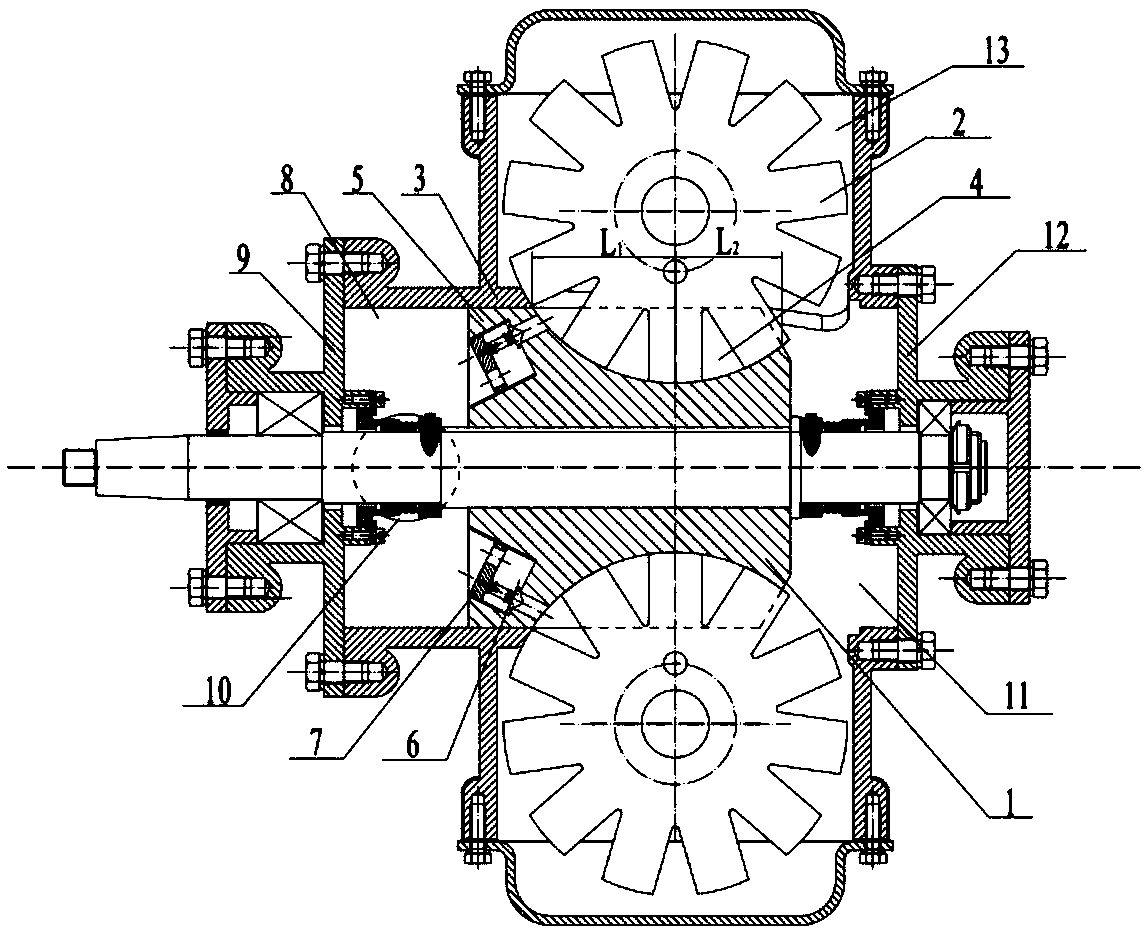

A cp type single screw pump

A single-screw pump and screw technology, which is applied in the direction of pumps, pump components, pump control, etc., can solve the problems of unable to realize the delivery of fluid medium, trapped liquid, etc., achieve the effect of simple structure, small pulsation of instantaneous flow rate, and reduce manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

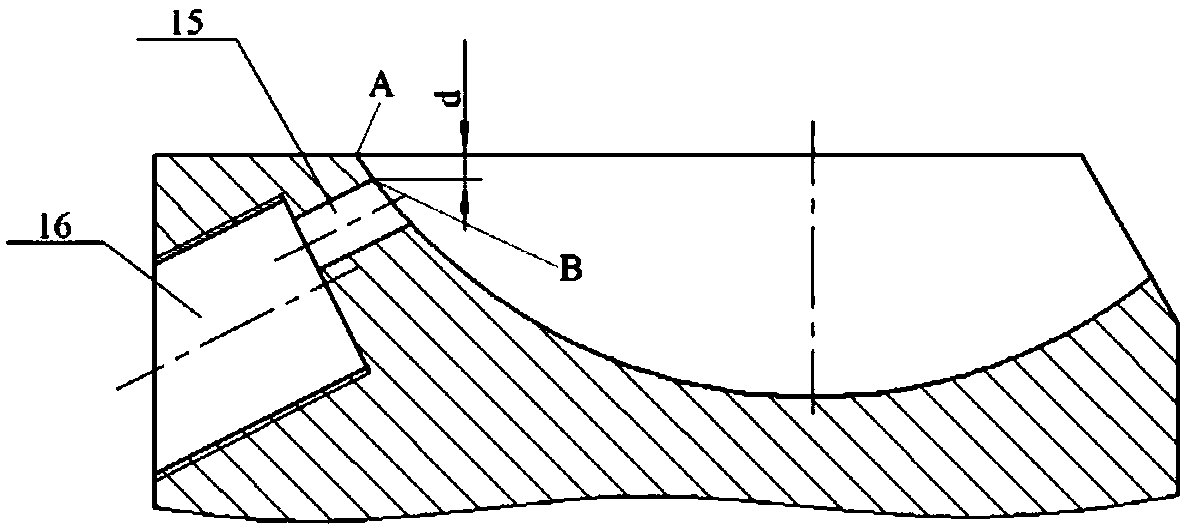

[0047] Embodiment 1: The pump rotates forward and the installed valve assembly is a ball valve or a cone valve. see Figure 5 , the valve plate 17 is provided with a second through hole 21, which is an eccentric hole. The lift limiter 19 of the valve assembly 7 is connected with the valve plate 17 through the thread at its tail. The spring 18 root is welded on the valve plate 17, and the valve core (ball or cone) 20 is welded on the spring 18 top. The center lines of lift limiter 19, spring 18 and spool 20 should coincide. It is required that the eccentricity of the centerline of the lift limiter 19 to the centerline of the valve plate 17 is the same as the eccentricity of the centerline of the first round hole 15 to the centerline of the second round hole 16 . The valve plate 17 on which the valve assembly is installed is screwed into the second circular hole 16, and the centerline of the lift limiter 19 is required to coincide with the centerline of the first circular hol...

Embodiment 2

[0052] Embodiment 2: The pump is reversed, and the installed valve assembly is a ball valve or a cone valve. see Image 6 , The valve plate 17 is provided with a second through hole 21, which is an eccentric hole. The lift limiter of the valve assembly 7 is physically connected with the screw behind the interface with the stepped first through hole 6 through the screw thread at the tail. The root of the spring 18 is welded on the interface of the stepped first through hole 6 , and the valve core 20 (ball or cone) is welded on the top of the spring 18 . The center lines of lift limiter 19, spring 18 and spool 20 should coincide. It is required that the eccentricity of the centerline of the lift limiter 19 to the centerline of the second circular hole 16 is the same as the eccentricity of the centerline of the second through hole 21 on the valve plate 17 to the centerline of the valve plate 17 . When the valve plate 17 is screwed into the first circular hole 15, the center li...

Embodiment 3

[0056] Embodiment 3: The pump rotates forward and the installed valve assembly is a strip valve. see Figure 7 , The valve assembly is composed of valve plate 17, valve plate 22 and lift limiter 23. A second through hole 21 is provided on the valve plate along a direction parallel to the centerline of the valve plate, and the second through hole 21 is an eccentric hole. The valve sheet 22 is a strip-shaped metal sheet with elasticity. The lift limiter 23 is a metal sheet with high rigidity. The lift limiter 23 and the root of the valve plate 22 are fastened on the valve plate 17 by screws 24 . The valve assembly 7 is screwed into the second round hole 16 and locked, and the valve plate 22 and the lift limiter 23 are located on the side close to the first chamber 8 . The rigidity of the used valve plate 22 should not only ensure that the cracking pressure δP is not too large to avoid additional energy loss, but also ensure that the valve plate 22 can quickly adhere to the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com