A mine explosion-proof trapezoidal airtight wall and its construction method

A mining explosion-proof and airtight wall technology, which is applied in mining equipment, earth square drilling, mining equipment, etc., can solve the problems of high cost, time-consuming and labor-intensive, time-consuming and labor-intensive, and achieve strong impact resistance and cushioning, The effect of convenient transportation and improved explosion-proof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

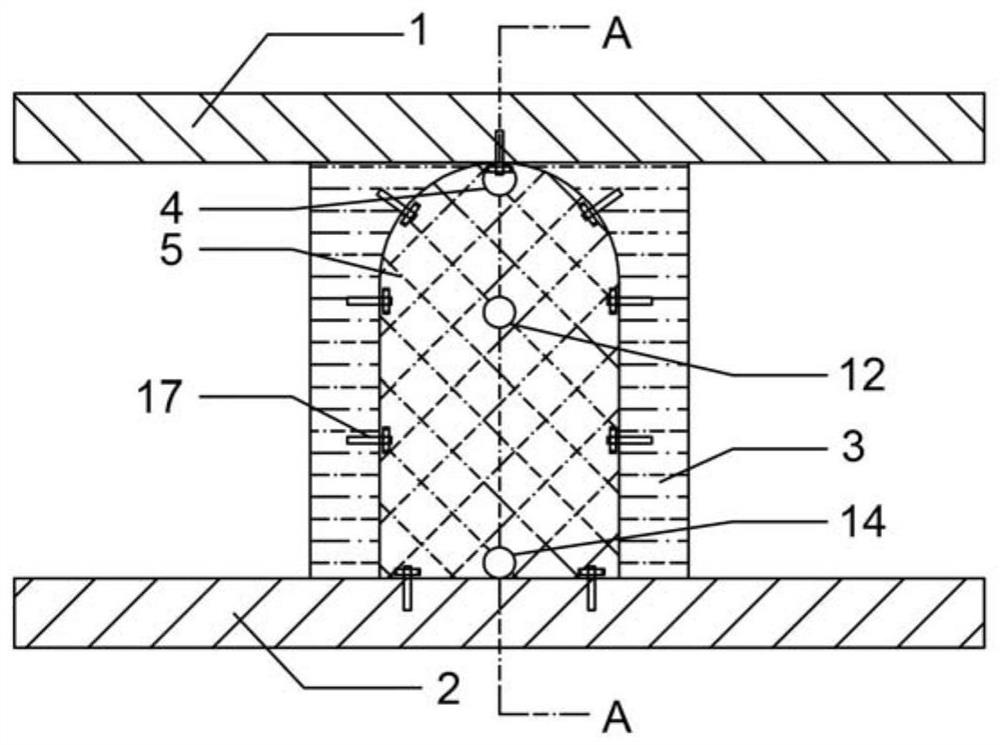

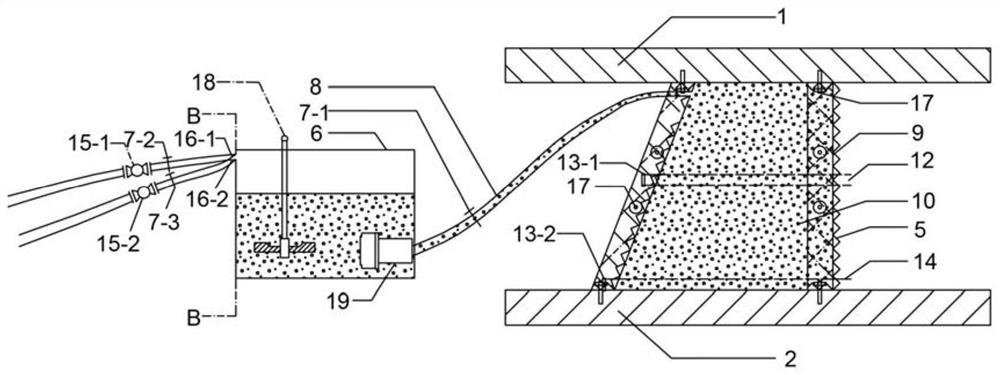

[0029] Taking the arch section roadway as an example below, the present invention will be further described in detail in conjunction with the accompanying drawings:

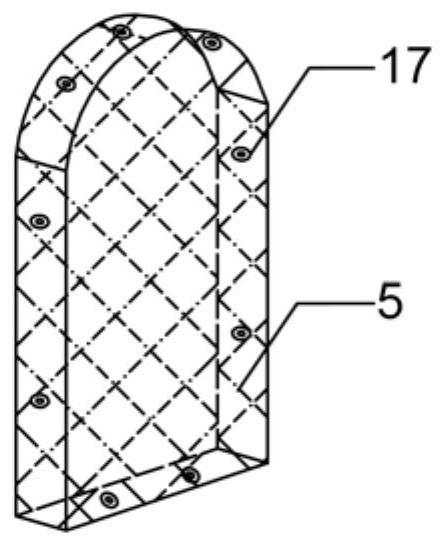

[0030] As shown in the figure: a trapezoidal explosion-proof airtight wall for mines, which is suitable for the rapid construction of airtight walls during thermal and dynamic disasters in coal mines. It mainly includes grouting hole 4, metal anchor net 5, sealing cloth 9, filling body 10, iron wire 11, pouring pipe 12, sealing valve 13, drainage pipeline 14, and expansion bolt 17.

[0031] Metal anchor net 5 is the anchor net used for mine support, and it is convenient to obtain materials. Metal anchor net 5 is fixed on surrounding rock 3 with expansion bolt 17, is connected as a whole with iron wire 11 simultaneously, to guarantee its stability. Wherein, the distance between each expansion bolt is 30~50cm.

[0032] The sealing cloth 9 inside the metal anchor net is a flame-retardant cloth, and is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com