Double buffering protecting method for mine draw shaft wall

A double buffering and shaft wall technology, which is applied in the double buffering protection of mine chute shaft wall and open-pit mine transportation system, can solve the problems of buffer pit floor wear and poor chute stability, and achieve the effects of nut protection, convenient construction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention will be further described in detail below in conjunction with the examples, but the embodiments of the invention are not limited thereto.

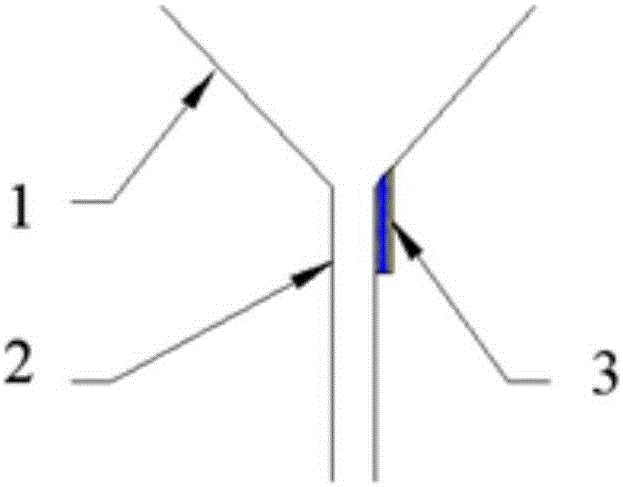

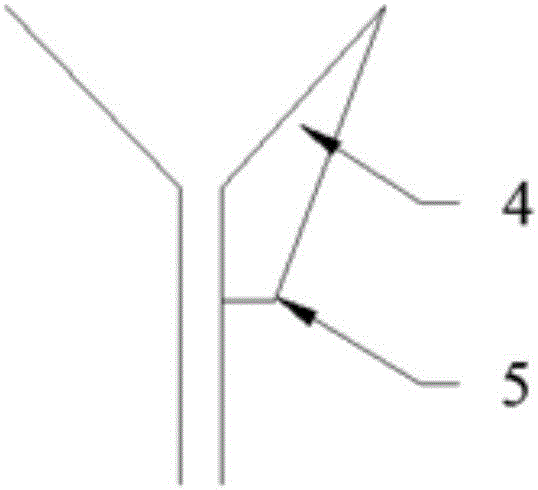

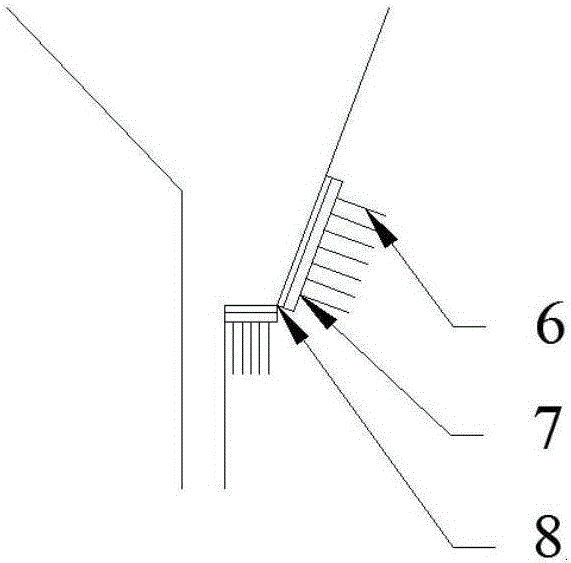

[0033] The double buffering protection method for the shaft wall of the mine shaft provided by the present invention specifically includes: determining the range where the ore collides with the shaft wall for the first time; carrying out side expansion excavation on the collision position of the shaft wall to form a step; Anchor rods are pre-embedded on the slope, and the ends of the anchor rods are threaded; hard polyurethane foam boards and manganese steel plates with grids are respectively arranged on the platform surface of the steps and the slope surface, as a flexible buffer layer and wear-resistant layer, ensuring that each There are anchor rods in the grid; the rigid polyurethane foam board and the manganese steel plate with grid are fixed with nuts, and a certain prestress is applied.

[0034] The specific ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com