Bushing

A sleeve and body technology, applied in the field of sleeves, can solve the problems of severe wear and short service life, and achieve the effect of reducing wear damage and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

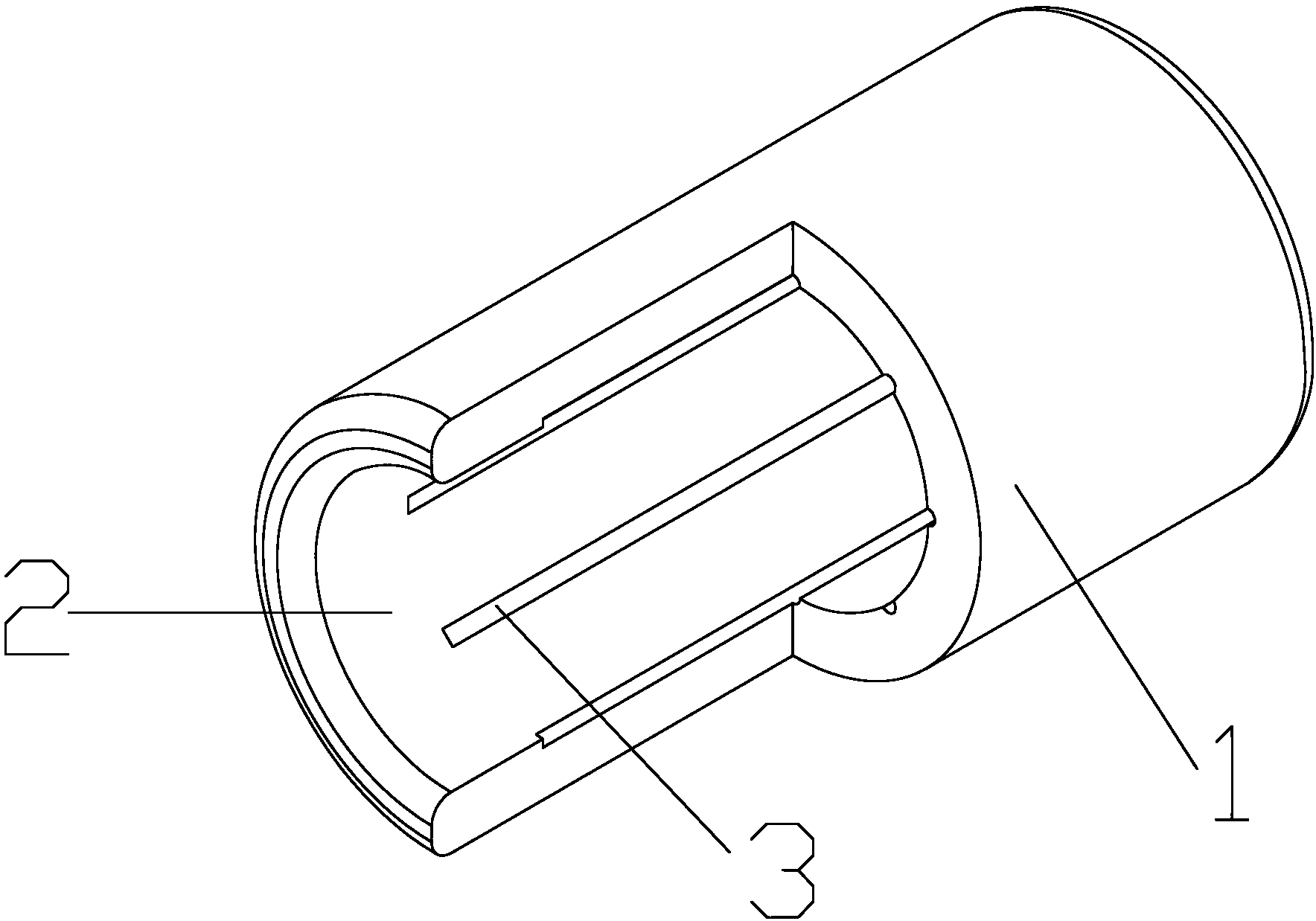

[0013] as attached figure 1 The sleeve of the present invention includes a sleeve body 1, a circular through hole 2 is opened at the middle position of the sleeve body 1; Several oil storage grooves 3 are evenly arranged at the positions; the length of the oil storage grooves 3 is less than the height of the sleeve body 1 .

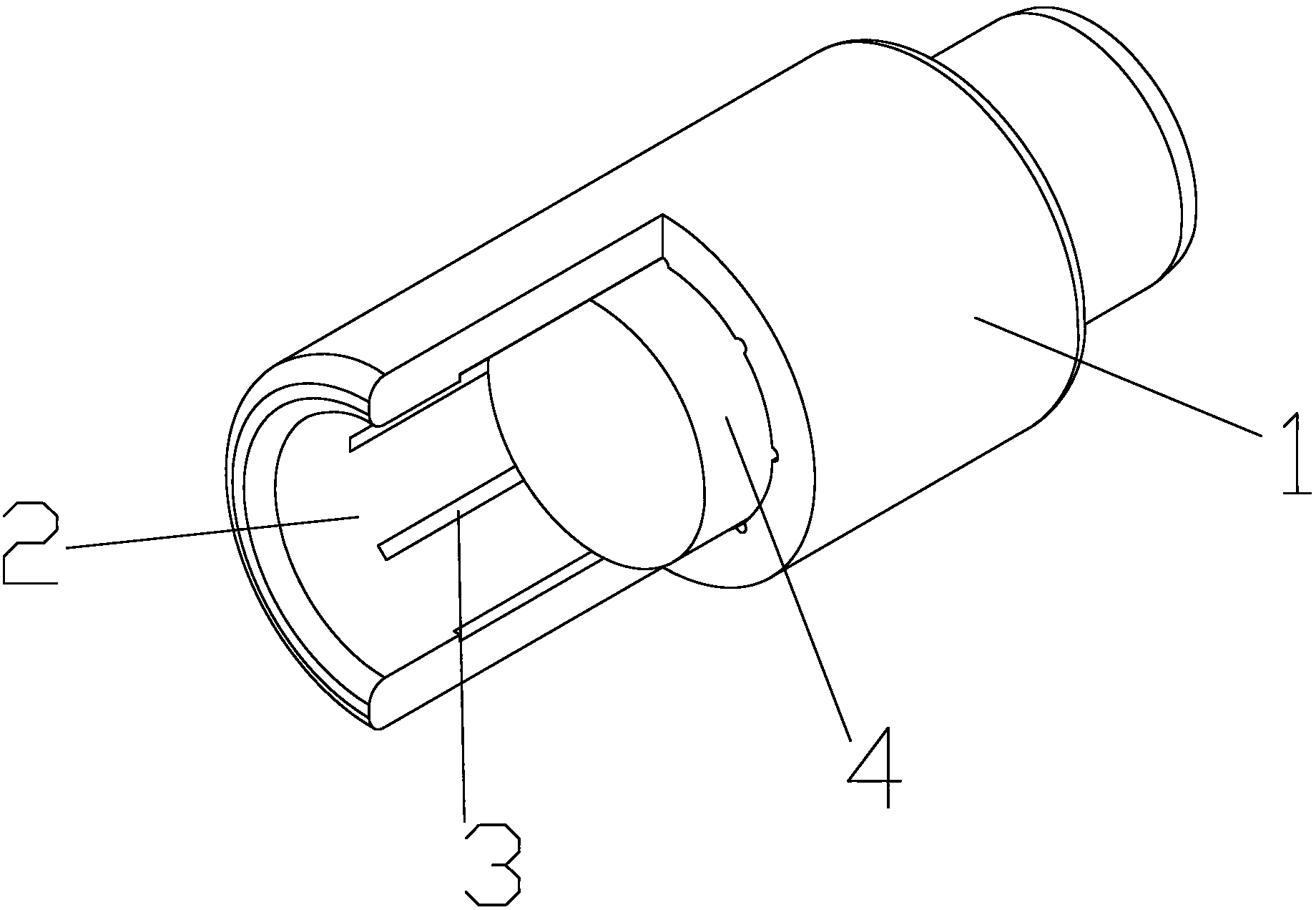

[0014] as attached figure 2 The sleeve of the present invention acts on the chain together with the pin shaft 4, and lubricating oil is added to the sleeve. The lubricating oil can be stored for a long time in the oil storage tank 2 provided on the inner wall of the sleeve. The wear-resistant damage of the chain itself is reduced, thereby prolonging the service life of the chain.

[0015] The above-mentioned embodiments are only to illustrate the technical conception and characteristics of the present invention. Substantial equivalent changes or modifications ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com