Coordinated mining by trucks with sub-section caving method with pillars

A technology of segmental caving method and truck, which is applied in the field of segmental caving method with pillars in the cooperative mining of trucks, to achieve the effect of improving the degree of mechanization, improving coordination and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

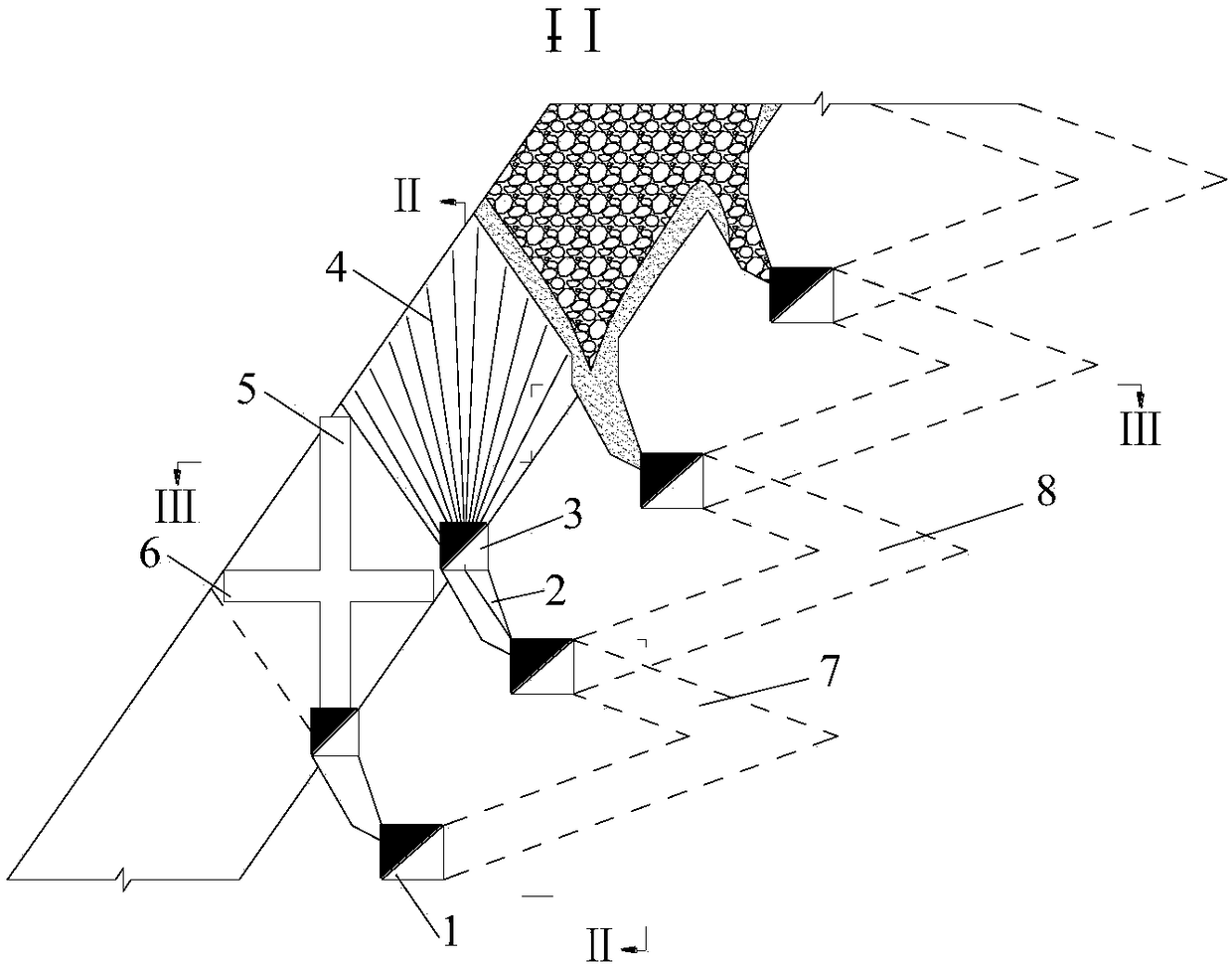

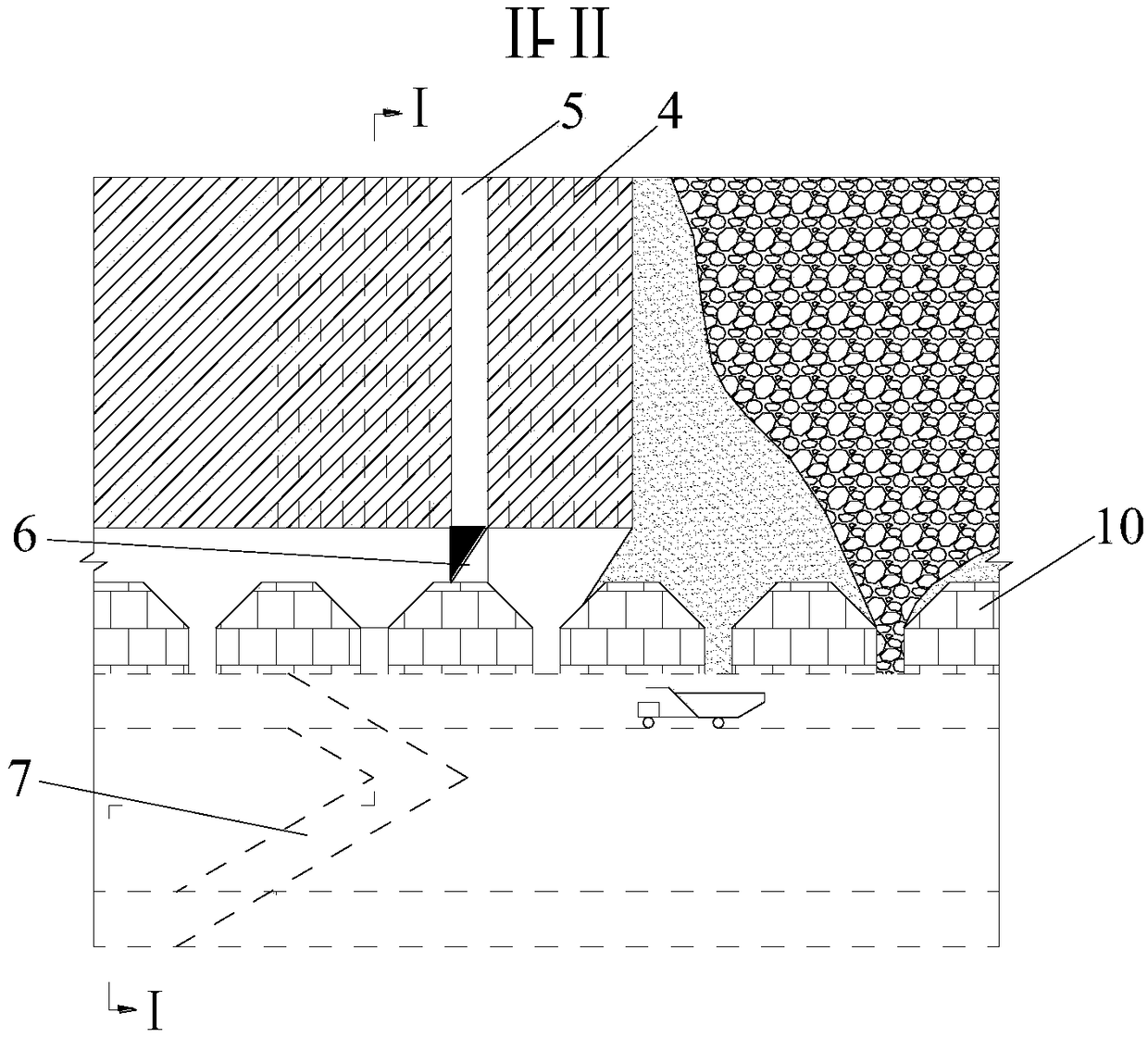

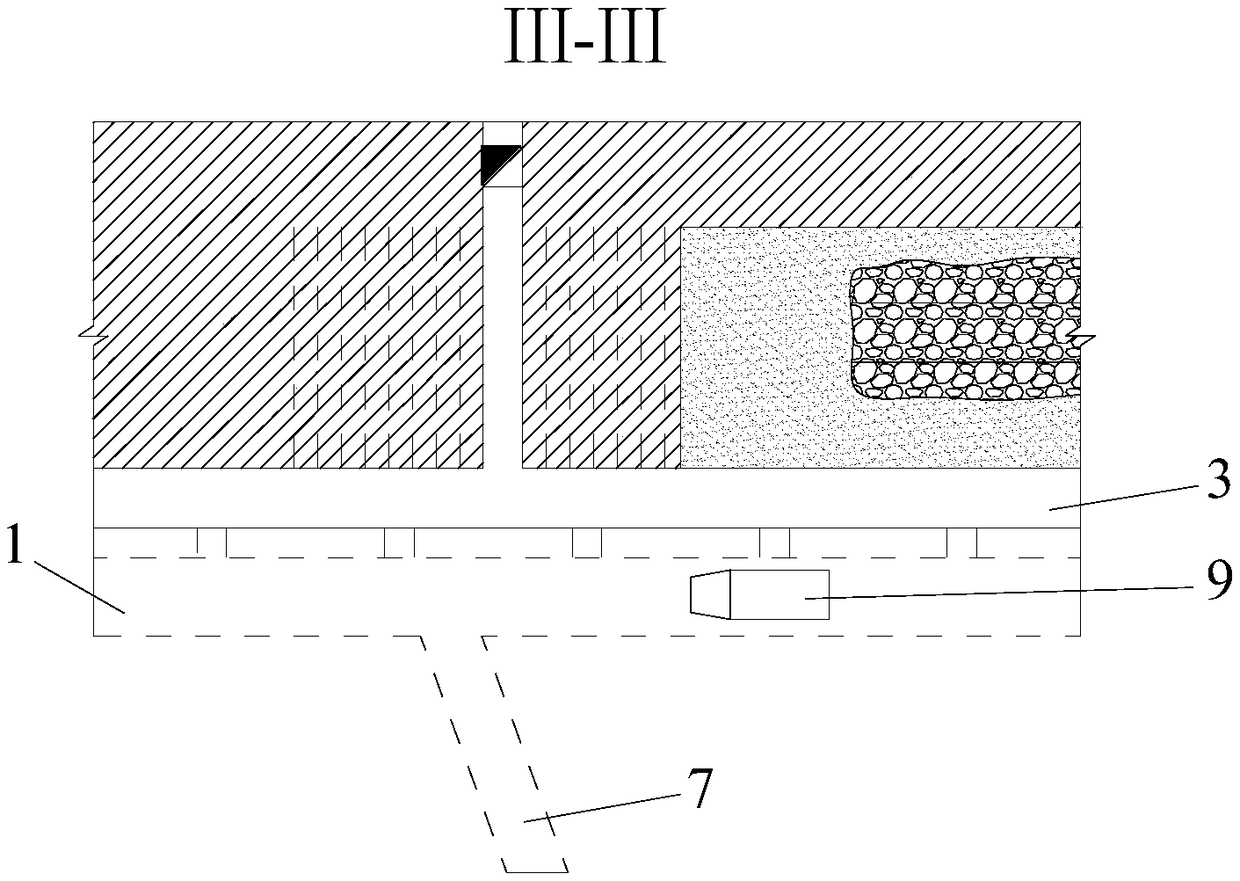

[0026] Such as Figure 1 to Figure 3 As shown, the truck cooperative mining of the present invention has the sub-section caving method of the bottom pillar, comprising the following steps:

[0027] (1) Divide the dipping-steep dipping thick orebodies above moderate stability in the surrounding rocks of the footwall or extremely thick orebodies with arbitrary dip angles into stages. The body tendency is divided into sections, the section height is 10-25m, and the section bottom column is 6-8m high.

[0028] (2) Before mining, dig a transport roadway 1 with a specification of 4m×3m in the surrounding rock of the ore body footwall, and dig a short chute 2 with a specification of 3m×3m in the segmental bottom pillar from bottom to top. Drilling roadway 3, and through rock drilling roadway 3, dig a cutting level entry 6 with a specification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com