Slurry marine gas hydrate mining method and mining device achieved by means of jet breaking and reverse circulation delivering

A technology of jet breaking and mining method, which is applied in the fields of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of complex sand isolation measures, in-hole accidents, damage, etc., and achieve sustainable mining and reduce mining. cost, and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

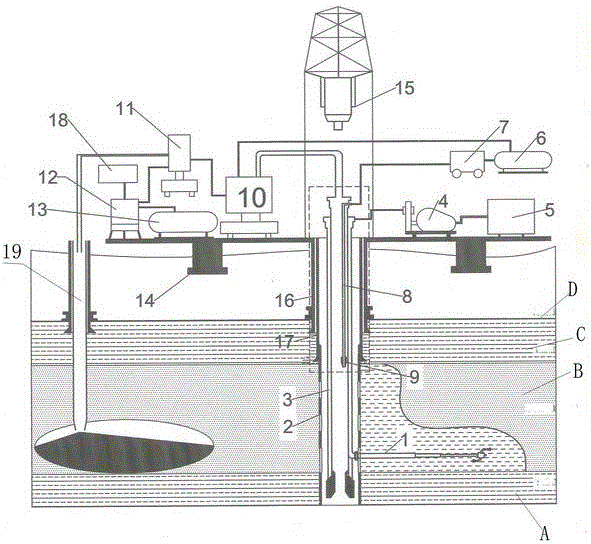

[0043] The extraction method of jet crushing and reverse circulation conveying slurry marine natural gas hydrate of the present invention comprises the following steps:

[0044] (1) The marine natural gas hydrate formation is broken up by high-pressure water jetting, and the jetted water forms a multiphase slurry mixture with the broken rock and soil and the broken hydrate;

[0045] (2) Transport the slurried mixture to the decomposition device and separation device on the sea level by means of reverse circulation;

[0046] (3) The decomposing device and separating device at sea level decompose the slurried mixture under reduced pressure, separate solid and liquid, and separate gas and liquid to obtain gas, solid and liquid respectively, and carry out corresponding utilization and collection.

[0047] The high-pressure water jet method adopts a retractable jet tool, which can move axially and radially, and realize large-scale mining in the horizontal section and the vertical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com