Reverse cumulative lifting construction method for single-layer spherical reticulated shell structure

A technology of construction method and reverse method, applied in building structure, construction and other directions, can solve the problems of high difficulty, large number of construction measures for single-layer spherical reticulated shell, long construction period, etc., to achieve simple construction, reduced risk of high-altitude operation, and elimination Rod damage and effects of rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

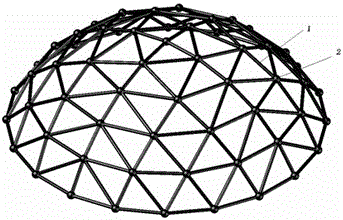

[0023] Such as Figure 1~11 Shown is one of the embodiments of the present invention. A theater in a certain district of a cultural and art center adopts a single-layer spherical reticulated shell structure, mainly composed of welding balls and round tubes. The spherical structure has a diameter of 20.6m, a height of 18.9m, and a height of 1.600m. The section of the components above the elevation is P203X10, and the joints use 500x20 welding balls. The sections of the components below the elevation of 1.600m (including 1.600m) are P245X12, and the nodes use 600x25 welding balls. The bottom is connected to the concrete through the support.

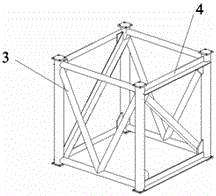

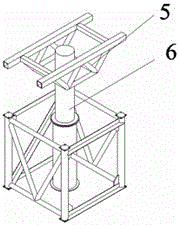

[0024] Using the cumulative jacking construction method, each time jacking up a standard section height of the jacking support frame, docking with the next outer ring until the jacking reaches the designated position, the installation of the structure is completed. The specific steps are as follows:

[0025] (1) Determine the plane position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com