Assembled joint being of spatial grid structure and composed of outer ring and hexagonal socket

A space grid, hexagonal technology, applied in building construction, special data processing applications, instruments, etc., to ensure construction quality, unique node form, and reduce the impact of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

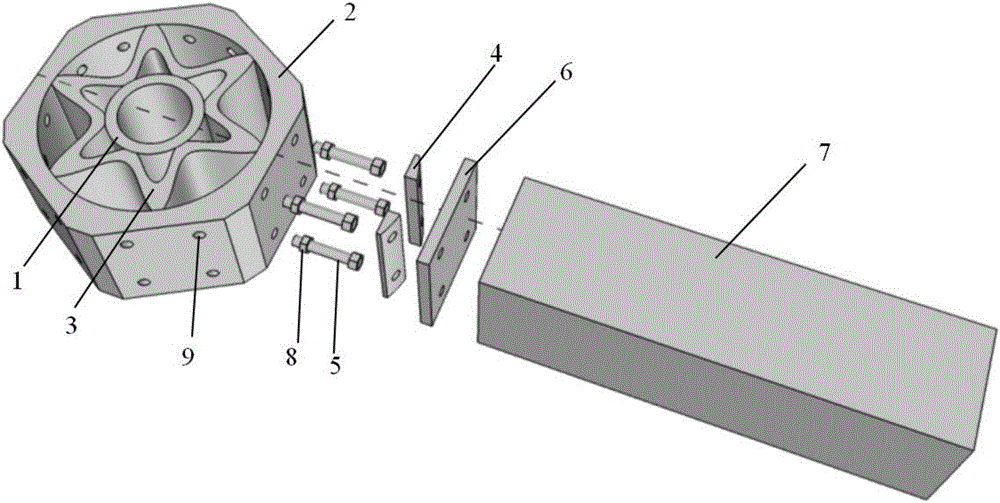

[0034] Such as Figure 1 to Figure 3 As shown, an assembled node with an inner hexagonal space grid structure of an outer ring includes an inner ring 1 , an outer ring 2 , a central ring 3 , bolts 5 , a sealing plate 6 and connecting rods 7 . The sealing plate 6 is a rectangular steel plate, and four third bolt holes 11 are evenly opened on the sealing plate 6 , the connecting rod 7 is a rectangular steel pipe, and the sealing plate 6 and the connecting rod 7 are welded.

[0035] Both the inner ring 1 and the outer ring 2 are cylinders, and the inner ring 1 has a circular hole 1 16 along the central axis, and the outer ring 2 has a circular hole 2 17 along the central axis.

[0036] The central ring 3 is a hexagonal star cylinder, and each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com