Testing device for vertical anti-uplifting test of spiral ground anchor and operation method of testing device

A technology of spiral ground anchor and testing device, which is applied in the testing of basic structures, construction, and basic structure engineering, etc., can solve the problems of inability to design for engineering, large error of test results, strong randomness of results, etc., so as to solve the problems of blindness and The effect of randomness, simple equipment, easy processing and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

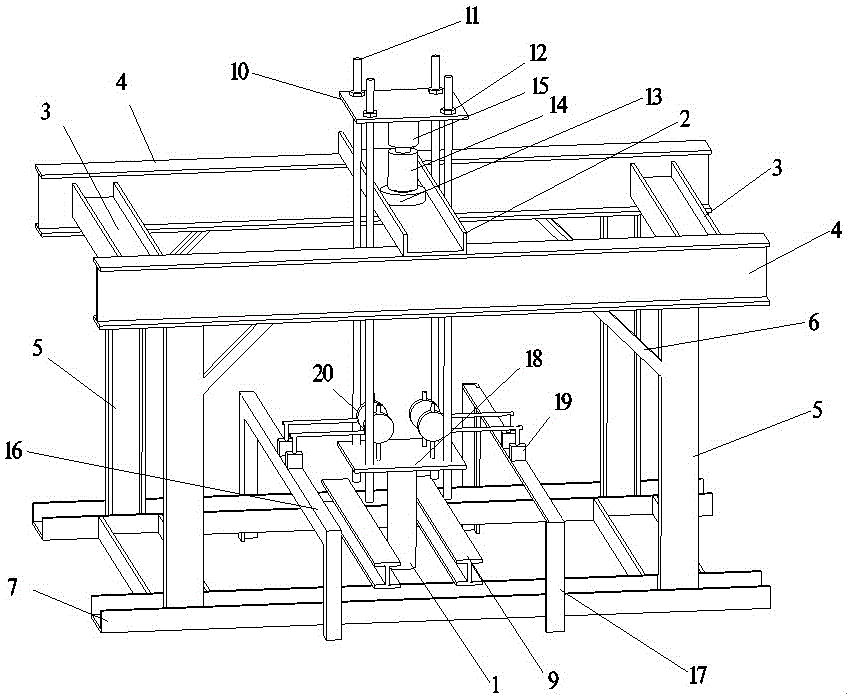

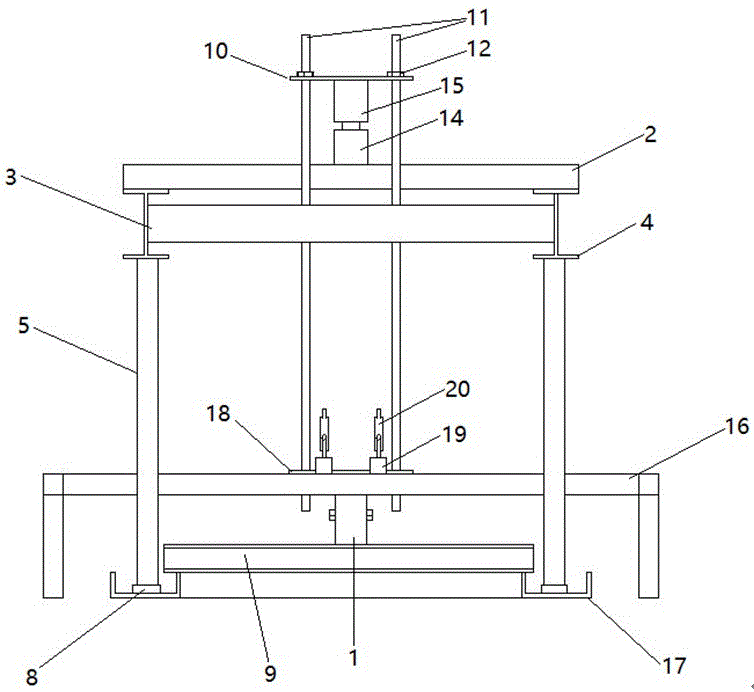

[0027] Example 1: If Figure 1~5 As shown, the test device above the ground pile head 1 of the spiral ground anchor consists of a central reaction beam 2 of the reaction support, a support beam 3, a force transmission beam 4, a force transmission column 5, a support brace 6, a bottom support beam 7, a fixed anchor Nail fixing hole 8, positioning beam 9, supporting top plate 10, continuous threaded rod 11, fixing nut 12, pressure sensor 13, jack 14, supporting pad 15, reference beam 16, reference beam column foot 17, top of pile head connector Square steel plate 18, displacement meter table seat 19, displacement meter 20, support beam 21 at the bottom of the support, four corners of perforation 22 of pile head connector, pile head connector steel cylinder 23 and pile head connection bolt 24 form.

[0028] The structure of the reaction force system is as follows: two force transmission beams 4 and two support beams 3 are connected to form the upper support structure, the central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com